Electrolytic Cells: A Buyer's Guide for Industrial Machinery in 2025

In the rapidly evolving industrial sector, electrolytic cells play a crucial role in various applications, from metal refining to chemical production. As we approach 2025, sourcing reliable and high-performance electrolytic cells from China has become a priority for many businesses. This guide will help you navigate the market and make informed decisions.

How to Find Reliable Electrolytic Cells from China in 2025

China remains a global leader in manufacturing industrial machinery, including electrolytic cells. To find reliable suppliers, consider these steps:

- Check certifications like ISO 9001 and CE

- Review supplier history and customer feedback

- Request product samples before bulk orders

- Verify production capacity and lead times

Top platforms like Alibaba and Made-in-China list reputable manufacturers with verified track records.

What Buyers Should Know Before Buying Electrolytic Cells from China

When importing electrolytic cells, consider:

- Shipping costs and import duties

- Voltage compatibility with your local grid

- After-sales support and warranty terms

- Customization options available

Always request detailed product specifications and confirm they meet your operational requirements.

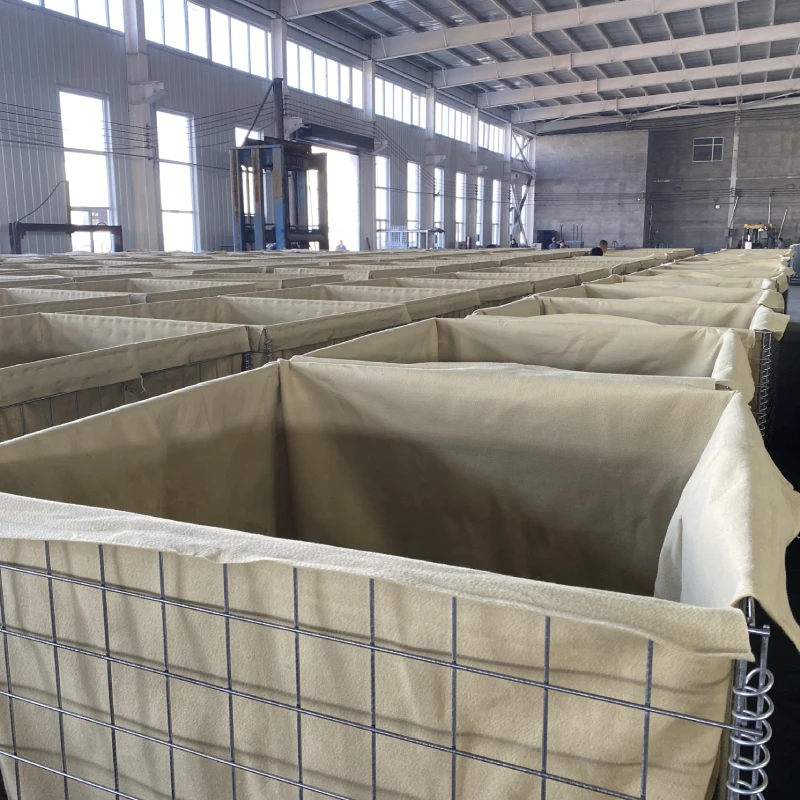

Types of Electrolytic Cells

Common electrolytic cell types include:

- Diaphragm cells: For chlorine and caustic soda production

- Membrane cells: Higher efficiency for chemical processes

- Mercury cells: Used in chlor-alkali processes (being phased out)

- Solid oxide cells: For high-temperature applications

Functions and features of Electrolytic Cells

Modern electrolytic cells offer:

- Energy-efficient designs reducing operational costs

- Corrosion-resistant materials for longer lifespan

- Precision control systems for consistent output

- Modular designs for easy maintenance

Advanced models may include automated monitoring and smart control features.

Scenarios of Electrolytic Cells

Electrolytic cells are essential in:

- Metal extraction and refining (aluminum, copper, zinc)

- Water treatment and purification systems

- Chemical manufacturing (chlorine, sodium hydroxide)

- Battery and energy storage technologies

How to Choose Electrolytic Cells

Selecting the right electrolytic cell depends on:

- Your specific industrial application

- Required production capacity

- Available space and installation requirements

- Budget and long-term operational costs

Consult with technical experts to match the cell specifications with your process needs.

Electrolytic Cells Q & A

Q: What's the typical lifespan of industrial electrolytic cells?

A: Quality cells last 5-8 years with proper maintenance, though membranes may need replacement sooner.

Q: How much energy do electrolytic cells consume?

A: Consumption varies by type, with modern membrane cells using 2,200-2,500 kWh per ton of product.

Q: Can electrolytic cells be customized for specific processes?

A: Yes, many Chinese manufacturers offer customization for electrode materials, cell size, and control systems.

Q: What safety features should I look for?

A: Prioritize cells with temperature controls, pressure relief systems, and leak detection.

Q: How do I maintain electrolytic cells?

A: Regular cleaning, membrane inspection, and electrolyte monitoring are essential for optimal performance.