Brackets: Essential Hardware for Industrial and Construction Needs

When it comes to industrial and construction projects, brackets play a crucial role in providing structural support and stability. Whether you're working on a small DIY project or a large-scale industrial build, understanding the different types, functions, and sourcing options for brackets can save you time and money.

How to Find Reliable Brackets from China in 2025

China remains a top destination for sourcing high-quality brackets at competitive prices. To ensure reliability, look for suppliers with certifications like ISO 9001 and positive customer reviews. Platforms like Alibaba and Made-in-China offer verified manufacturers. Always request samples before bulk orders to check material quality and durability.

What Buyers Should Know Before Buying Brackets from China

Before purchasing, consider lead times, shipping costs, and minimum order quantities (MOQs). Negotiate terms clearly and confirm payment methods. It's also wise to check if the supplier offers customization options to meet your specific project requirements.

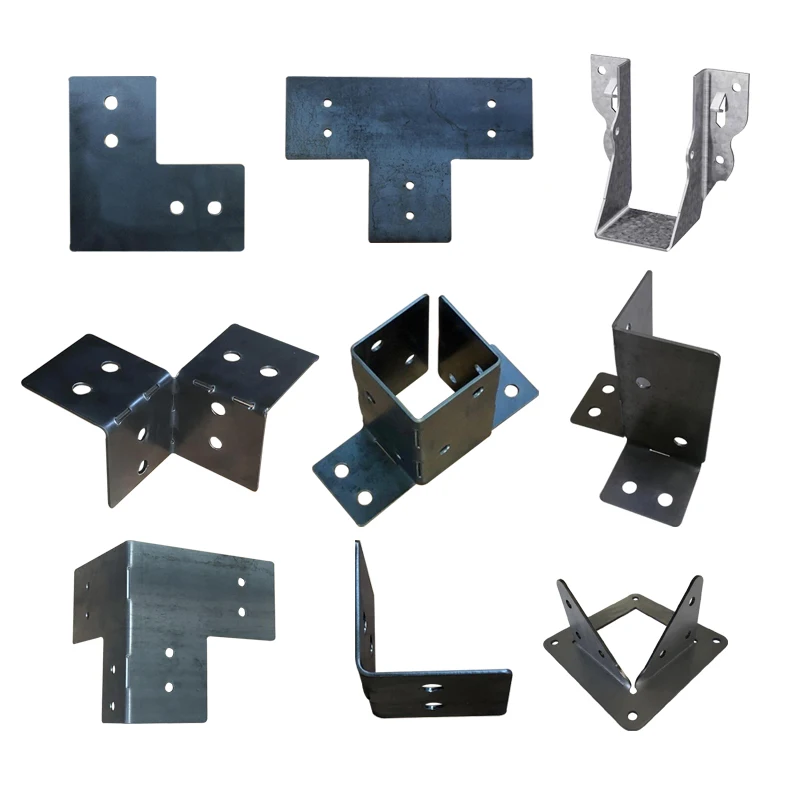

Types of Brackets

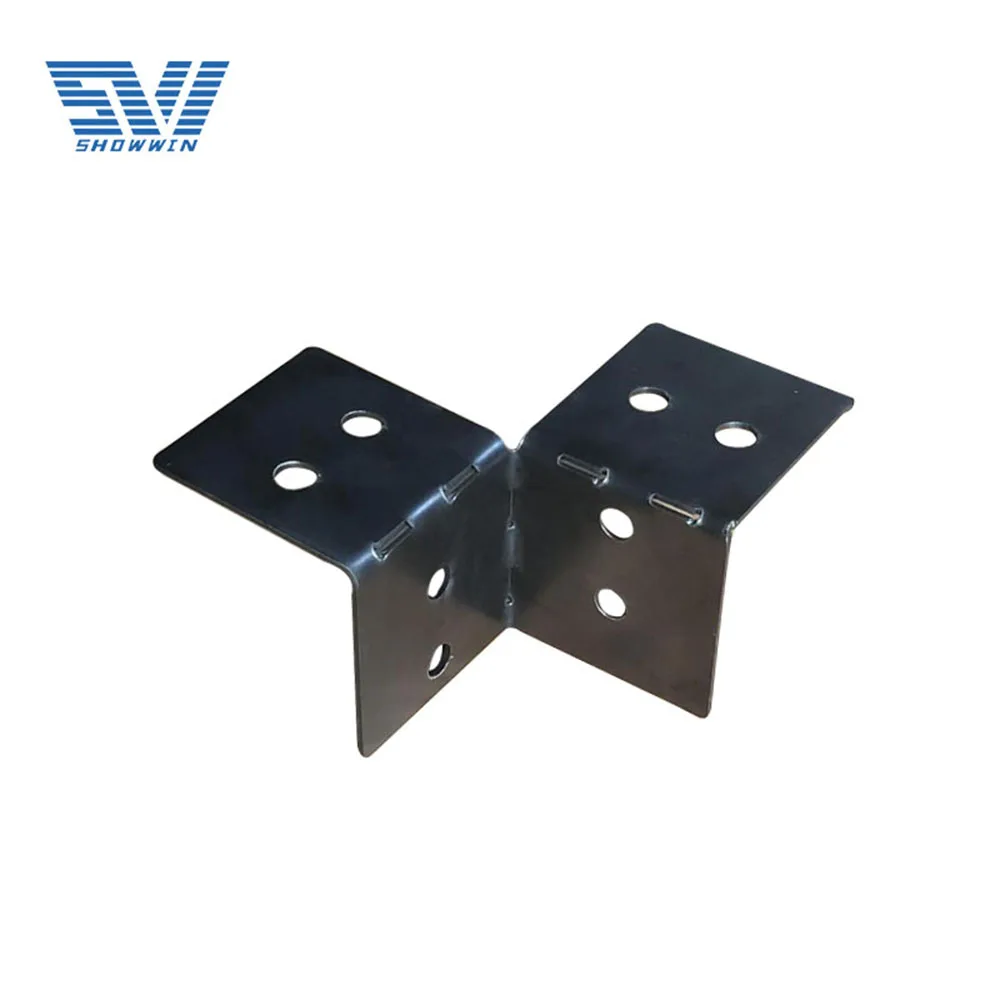

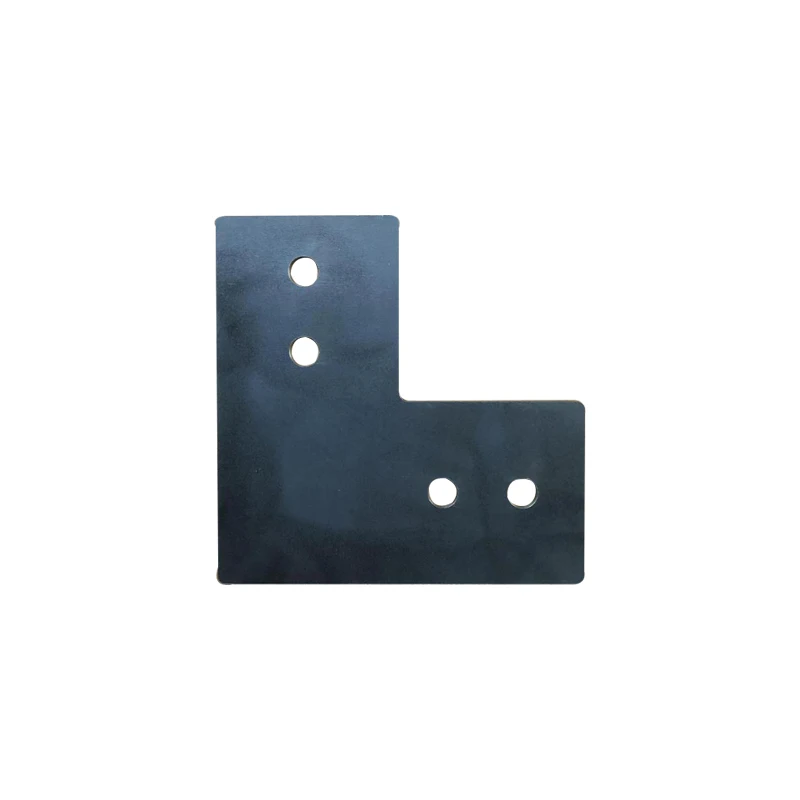

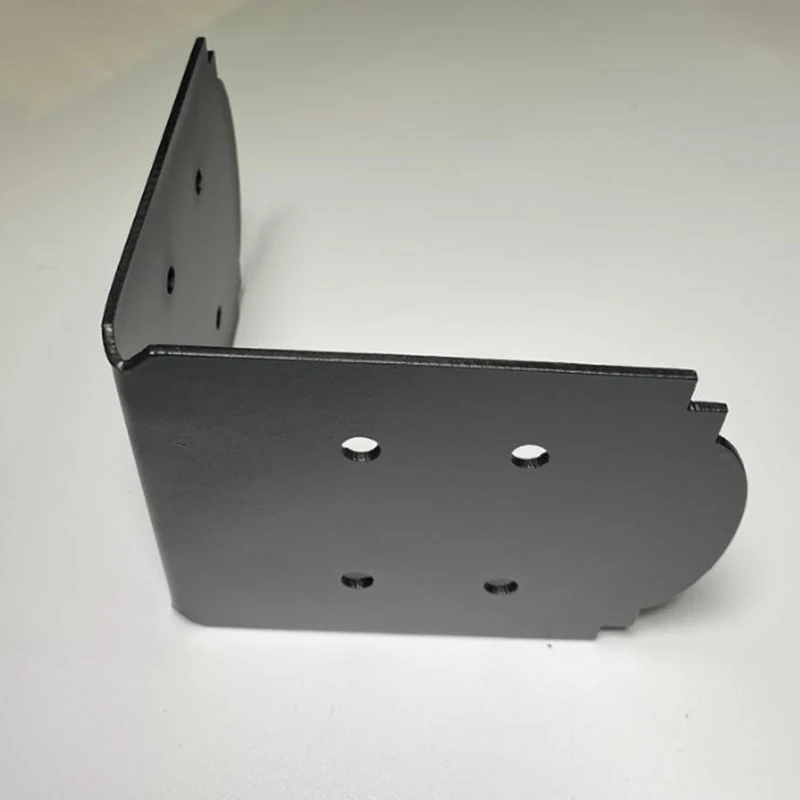

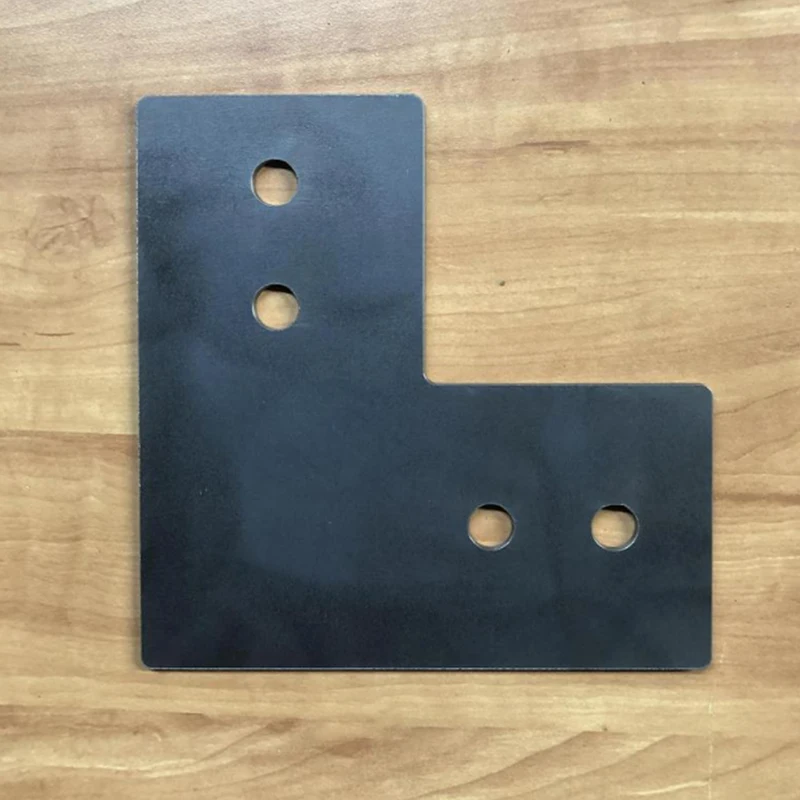

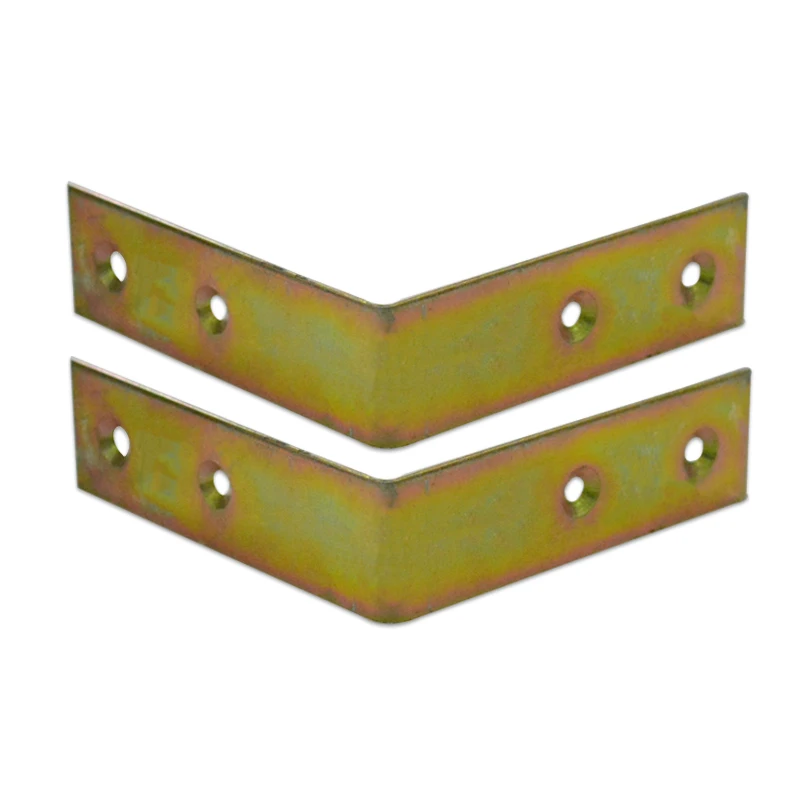

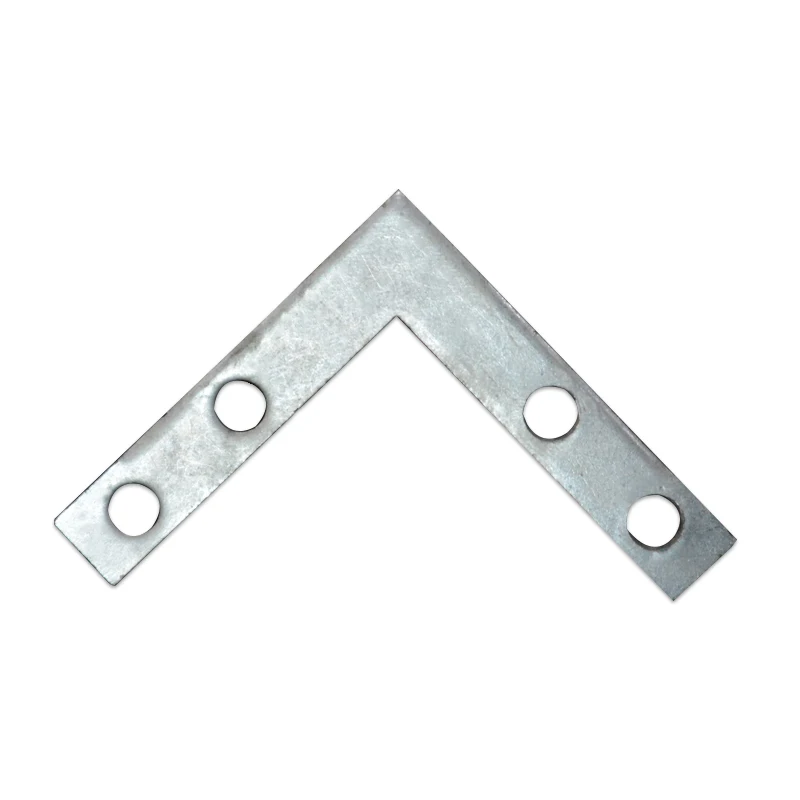

1. L-Shaped Brackets: Ideal for corner joints and right-angle supports.

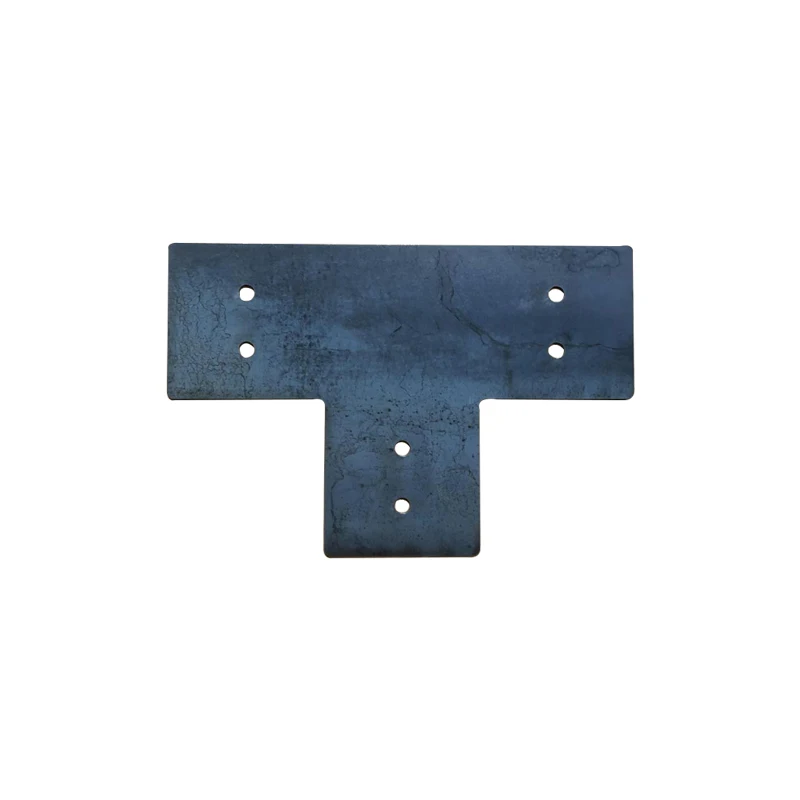

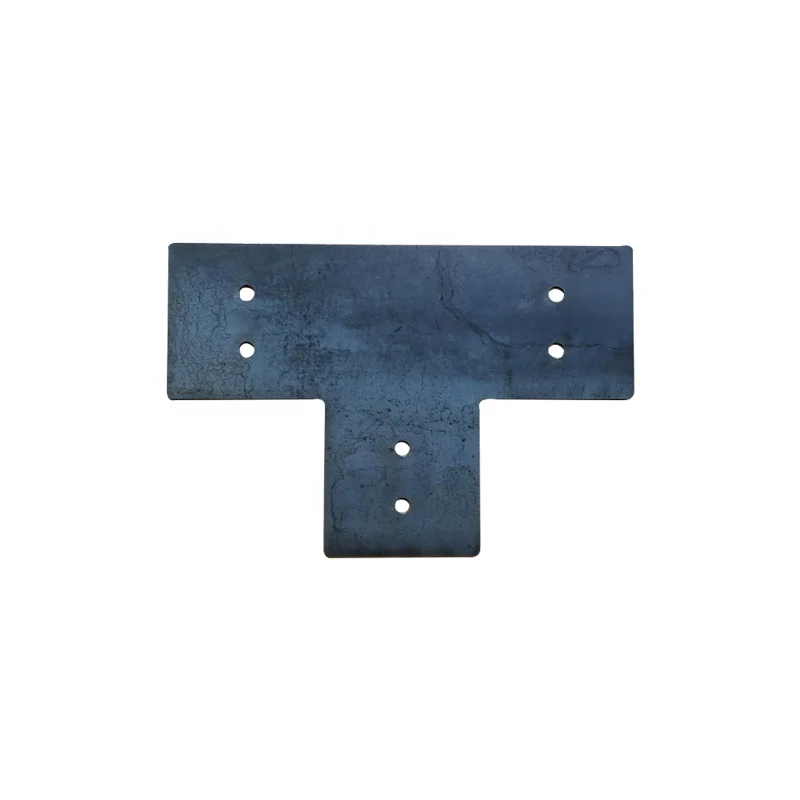

2. T-Shaped Brackets: Used for T-joints in framing and structural applications.

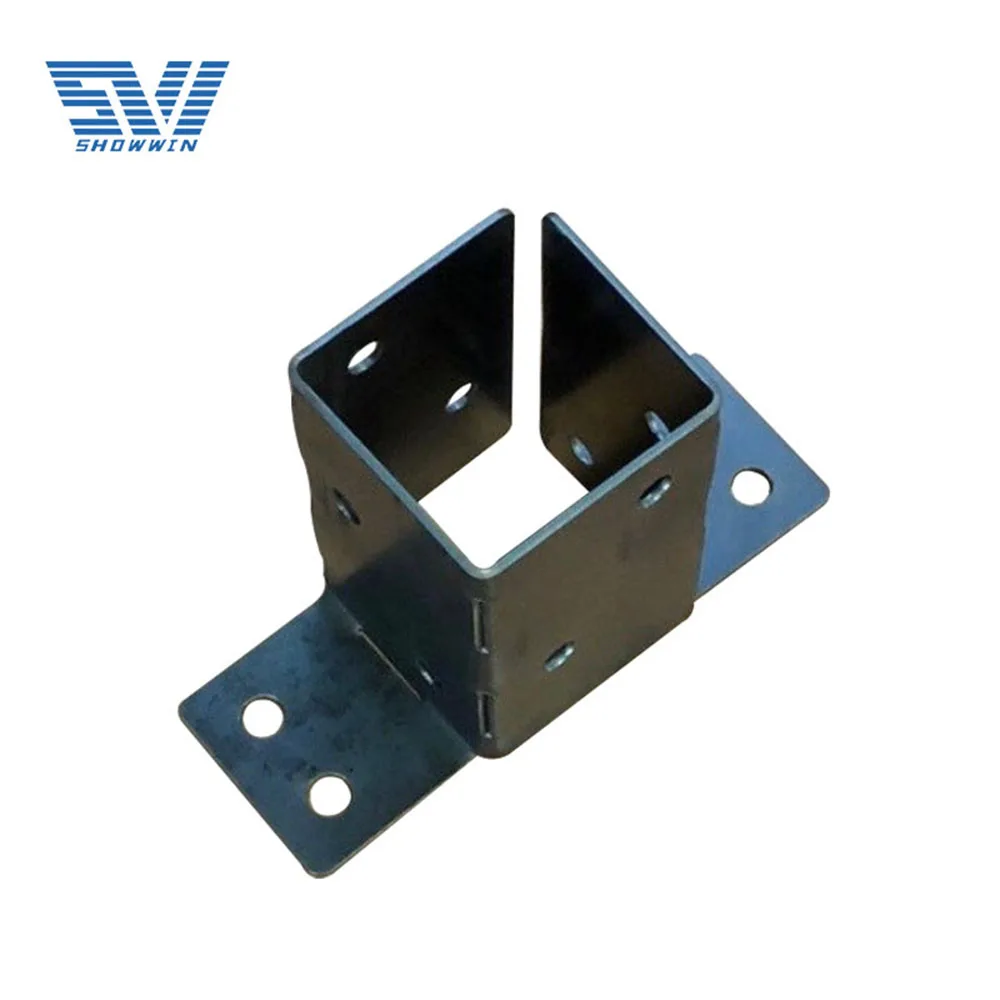

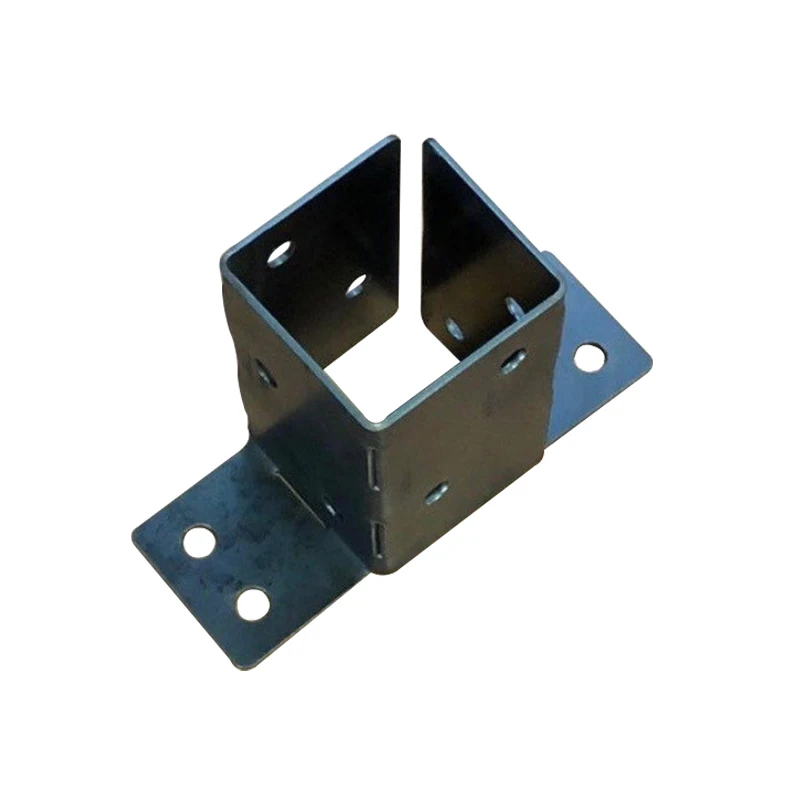

3. U-Shaped Brackets: Perfect for clamping or holding pipes and rods.

4. Flat Brackets: Versatile for mounting and securing flat surfaces.

5. Heavy-Duty Brackets: Designed for high-load applications in construction and machinery.

Functions and Features of Brackets

Brackets provide stability, distribute weight, and reinforce joints. Key features include corrosion resistance (galvanized or stainless steel), load capacity, and ease of installation. Some advanced models come with pre-drilled holes for quick assembly.

Scenarios of Brackets

Construction: Used in framing, roofing, and scaffolding.

Furniture: Essential for assembling shelves, cabinets, and tables.

Machinery: Support heavy equipment and industrial machines.

DIY Projects: Handy for home repairs and custom builds.

How to Choose Brackets

Consider the material (steel, aluminum, or plastic), load requirements, and environmental conditions (indoor vs. outdoor). For heavy-duty applications, opt for steel brackets with anti-rust coatings. Always match the bracket type to your specific use case.

Brackets Q & A

Q: What materials are best for outdoor brackets?

A: Stainless steel or galvanized steel brackets are ideal for outdoor use due to their rust resistance.

Q: Can I customize brackets for unique projects?

A: Yes, many suppliers offer custom sizes, shapes, and finishes to meet specific needs.

Q: How do I verify a supplier's reliability?

A: Check certifications, customer reviews, and request product samples before placing large orders.

Q: What’s the average lead time for orders from China?

A: Typically 15-30 days, depending on order size and shipping method.

Q: Are plastic brackets durable for heavy loads?

A: No, plastic brackets are best for lightweight applications. Opt for metal brackets for heavy-duty use.