We provide custom cnc machining, cnc milling, cnc turning, sheet metal stamping, sheet metal bending, EDM, extrusion, forging,casting, welding, product assemly & packaging services. We have serviced 3000 buyers from worldwide and helped save 60% cost compare to manufacturing at local.

Other recommendations for your business

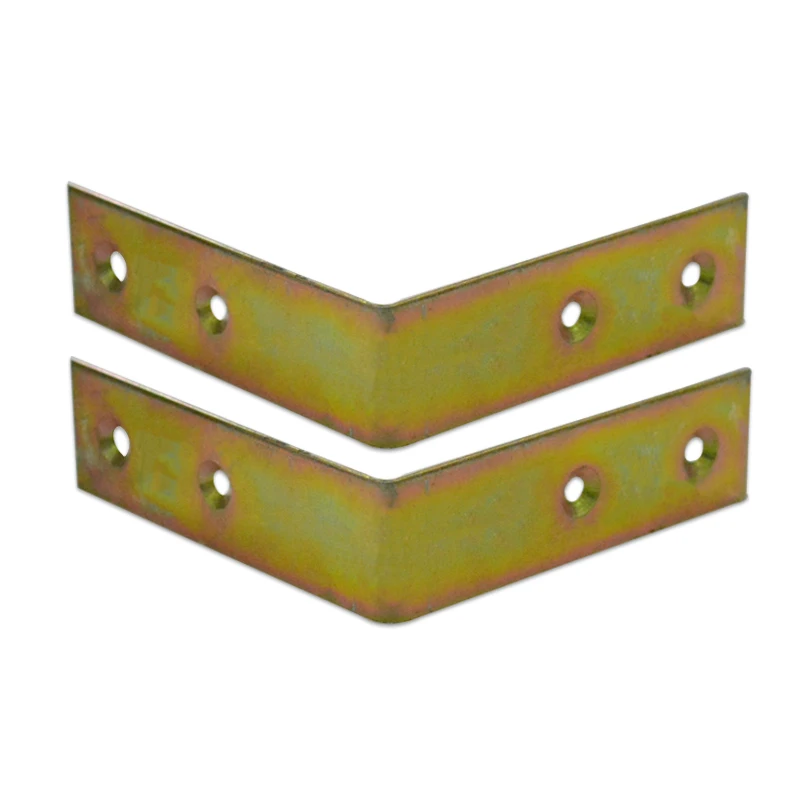

Product Description

Processing | We will provide samples according to customer's drawing for approval. Then arrange the production and confirm the delivery date according to the Purchase Order.Normally, the lead time for production is 15-20 working days. | ||||||

Material range | Stainless Steel, Brass,Copper, Brozone, Aluminum, Steel, Carbon Steel etc. | ||||||

Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc | ||||||

Payment | 30% in advance, 70% before shipment | ||||||

Cases

We invite you to contact us, no order is too big or too small, welcome send drawing or sample to start metal processing fabrication

Company Profile

About us

Shuowei Metal is Specialied in machine manfacturing and custom fabrication of steel, stainless and aluminum. We have an extensive array of equipment and experienced personnel to ensure that your project will be completed to the highest quality standards and on time.

Production Process

CNC Milling

CNC Milling has several advantages over other manufacturing processes. Complex shapes and high dimensional tolerances are possible. Smooth finishes can be achieved. CNC milling can produce almost any 2D or 3D shape provided that the rotating cutting tools can reach the material to be removed. Examples of parts include engine components, mold

tooling, complex mechanisms, enclosures, etc.

tooling, complex mechanisms, enclosures, etc.

CNC Turning

CNC turning produces parts by “turning” rod material and feeding a cutting tool into the turning material. On a lathe the material

to be cut rotates while a cutter is fed into the rotating workpiece. The cutter can be fed at a variety of angles and many tool shapes can be used.

to be cut rotates while a cutter is fed into the rotating workpiece. The cutter can be fed at a variety of angles and many tool shapes can be used.

Metal Stamping

Using progressive tooling and secondary tooling to produce small and large parts, we are able to offer quick turnarounds on prototypes and production runs.

Metal Cutting

Laser cutters produce metal parts from sheet material using a laser beam to vaporize sections of the workpiece.

we offers a cost-effective cutting solution whether you need a single part, batch of prototypes, or a production order.

we offers a cost-effective cutting solution whether you need a single part, batch of prototypes, or a production order.

Our workshop

FAQ

Q1:How about the sample policy?

A1:Samples can talk with customer service

Q2: Can you make my designs?

A2:Yes, customer design,especially OEM, is welcomed.Please feel free to send us your design for development.

Q3: Do you have a preferential policy for brand companies?

A3:Yes, we have certain preferential policies for our own branded company and our VIP customer list.

Q4: What is your minimum order quantity? Can I mix different styles to a start order?

A4:Yes,MOQ is needed and of course you can mix colors and styles. Any question,contact with us.

Q5: Why does the quote on the website not match the actual price?

A5:The price on the website is only a rough quotation.Many factors such as quantity,material cost and exchange rate will affect the price,so the real price will be subject to our final confirmation.

Q6: How can I place orders?

A6:Type,quantity and size are basic elements. Customer must give us these information for making.Any doubts,please contact with us.

Q7: Can I change my order once it is confirmed?

A7:We regret that we are unable to remake it once one order is produced. We don’t have any refund policy for confirmed and

flawless product, but we accept your changes before we send the order to production.

A1:Samples can talk with customer service

Q2: Can you make my designs?

A2:Yes, customer design,especially OEM, is welcomed.Please feel free to send us your design for development.

Q3: Do you have a preferential policy for brand companies?

A3:Yes, we have certain preferential policies for our own branded company and our VIP customer list.

Q4: What is your minimum order quantity? Can I mix different styles to a start order?

A4:Yes,MOQ is needed and of course you can mix colors and styles. Any question,contact with us.

Q5: Why does the quote on the website not match the actual price?

A5:The price on the website is only a rough quotation.Many factors such as quantity,material cost and exchange rate will affect the price,so the real price will be subject to our final confirmation.

Q6: How can I place orders?

A6:Type,quantity and size are basic elements. Customer must give us these information for making.Any doubts,please contact with us.

Q7: Can I change my order once it is confirmed?

A7:We regret that we are unable to remake it once one order is produced. We don’t have any refund policy for confirmed and

flawless product, but we accept your changes before we send the order to production.

Supplier's popular products

Contact Supplier

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.