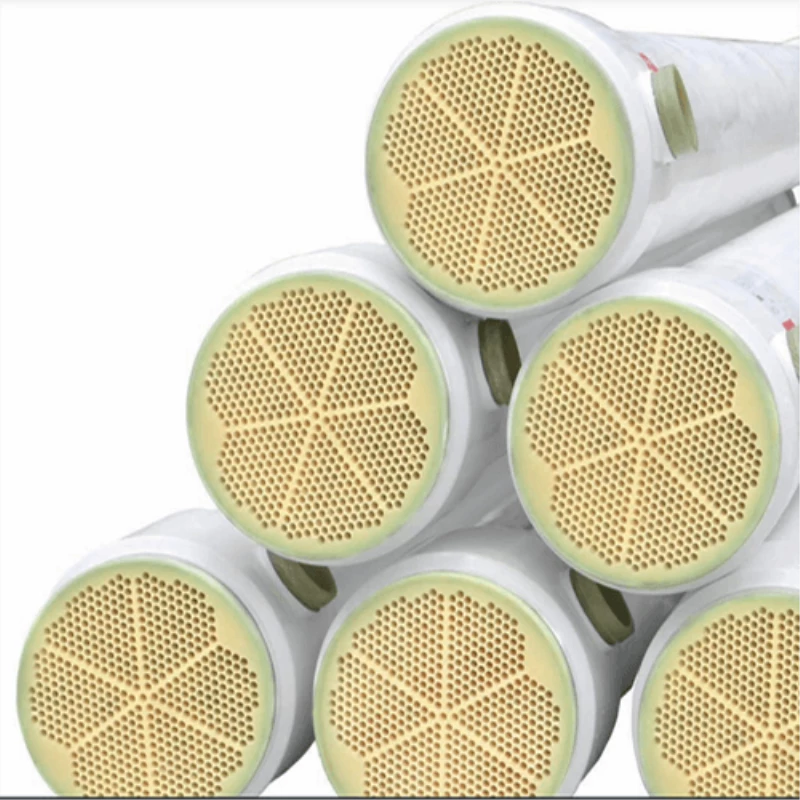

Xinsiwen electrophoresis equipment accessories ultrafiltration tube conductive ion anode membrane roll ultrafiltration membrane tube

- Tubular membrane material

- PVDF、PES、PAN、PS

- Molecular weight cut-off

- 5

- Membrane tube diameter (inner diameter)

- 000-250

The tubular membrane system is an external filtration system. For high solid content and high SS liquids, we use adjustable cross-flow speed to make the membrane operate under optimal conditions and extend the service life of the membrane. At the same time, it has the characteristics of easier cleaning and maintenance, independent closed pipeline operation, and overall system independence. SUN tubular membranes first recommend cross-flow filtration technology, which can reduce the number of cleaning times and downtime, thereby maintaining a higher water flux. Some membrane products can also be backwashed. When necessary, permeate or chemical cleaning agents can be used for backwashing to effectively extend the life of the membrane. Main application areas of SUN tubular membranes/Product range of SUN tubular membranes:

High-concentration sewage treatment● Garbage leachate treatment

● Alkali recovery pretreatment

● Special chemical wastewater

(coking, leather, textile, etc.) treatment

● Oilfield produced water reinjection

● Emulsified oil treatment of low-concentration sewage

● Electronic wastewater treatment

● Municipal sewage, etc.

Material separation

● Food, biopharmaceutical fermentation broth clarification

● Electrophoretic paint and other material recovery

● Tea beverage, juice clarification and concentration

Product parameters:

Tubular membrane material: PVDF, PES, PAN, PS

Molecular weight cutoff: 5,000-250,000Da

Membrane tube diameter (inner diameter): 5-12.7mm

Industrial membrane assembly conventional diameter: 3', 4', 6', 8', 10, length: 3m, 3.66m, 4m Experimental membrane assembly conventional diameter: 1~3", length 0.5~1.5m

At the same time, it has high strength, anti-pollution, anti-oxidation (PVDF material chlorine resistance 250,000ppm·h), acid and alkali resistance (tolerance to 20% NaOH) membrane, pure water flux up to 800LMH, some membrane products can work at a pressure of up to 10bar, working temperature up to 90℃. Even if the concentration of activated sludge is as high as 40g/L, the flux is still as high as 70-150LMH.

8" and 10" large membrane components can greatly reduce the investment and operation costs of large projects, and are widely used in high-concentration industrial wastewater such as landfill leachate, pharmaceutical wastewater, alkali recovery, oily wastewater, electronic wastewater, coking wastewater, and food, fermentation broth, tea beverages and other material separation fields.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.