Recycling tire rubber powder

Ground vulcanized rubber

Recycling tire rubber granules

recycled tire crumb

Description

The tire rubber powder uses 900 to 1200 waste tires as the main raw material, and uses the air turbine refrigeration low-temperature pulverization method to produce 40 mesh (0.425mm) to 200 mesh (0.0750mm) tire rubber powder. It has high fineness, high tear strength and specific gravity. With the characteristics of small size, good fluidity, etc., we can produce various specifications of tire rubber powder, waste tire particles and other products according to customer needs to ensure that the selection of waste tires is genuine and the quality is stable and long-term sufficient supply.

The production process

Comprehensive crusher: crush the waste tires from which the bead wire has been removed into various rubber blocks of required specifications;

Rubber Crusher: Crush a certain size of rubber block into 6-12mm rubber pellets at room temperature;

Rubber fine crusher: crush 6-12mm rubber pellets into 1-3mm rubber pellets, and separate the rubber from the fiber in the tire;

Fiber sorting machine: Separate nylon fibers from waste tires at room temperature;

Fine powder mill: grind 1-3mm rubber particles into 0.75-0.075mm (30-200 mesh) fine rubber powder;

Each particle size application field

5-10 mesh: runway, school sports field, garden trail, bowling alley, sidewalk, composite rubber floor tiles, anti-static floor tiles, artificial turf, playground, artificial grass football field, kindergarten sports field and entertainment field, tennis and basketball field. 10-20 mesh: rubber floor tiles, plastic runways, lawn quartz sand, cottonseed skin pellets, tennis courts, volleyball courts, golf courses, airplane courts, basketball courts and recreational fields, EPDM safety mats, gym mats, various types Stadium mats. 30 mesh: insulating rubber material, waterproof material, shockproof, gasket, waterproof coiled material for roof and wall, modified asphalt additives, reclaimed rubber, livestock grass mat, mudguard, multifunctional mat, stable mat.

40 mesh: reclaimed rubber, waterproof membrane, modified asphalt additives, carpet liners, sleepers, rubber sheets, livestock straw mats, rubber waterstops, gate waterstops, bearings, sealing strips, buffers, brake linings Covers, drain pipes, gloves, rubber bands, elastic bands, roof signs, brick roof liners, sanitary pumps, corner glue, wheels, sand pump rubber pads, mudguards, multifunctional mats, stable mats, flame retardant materials , Sound insulation materials, rubber and plastic bottoms, window sealing tapes and other rubber products and agricultural rubber (latex) rubber products.

60 meshes: sleepers, rubber sheets, waterproof coiled materials, reclaimed rubber, tire inner pads, car body bottom seals, waterproof rings, miscellaneous rubber parts and replacement of virgin rubber to make rubber products.

80 mesh: modified asphalt additives, reclaimed rubber, waterproof membranes, large and small tire additives, sleepers, deceleration road crowns, sealing strips, buffers, foam rubber, pearl cotton pads, rubber pistons, brake bushings and other rubber products.

100 mesh: auxiliary materials for automobile bias tires, special padding for shoe-making, sports equipment tires.

120 mesh: thermal insulation material plastic pipe additives, automotive bias tire auxiliary materials, automotive refurbished outer pads, shoe-making special fillers, chemical sealants, various rubber cements.

200 mesh: building materials coatings, automobile tires, substitute raw rubber to make various rubber products. You can also recycle waste oil and bury it deep underground.

Applicable products

highway asphalt improvement, waterproof coiled materials, modified concrete, modified coatings, railway sleepers, rubber bricks, machine mats, roadbed mats, cushions and other gaskets, as well as mudguards, sound-absorbing materials, road caulking paste , Shoe materials, carpet pads, tire inner pads, car body bottom seals, waterproof rings, miscellaneous rubber parts, etc.

Application details

1. Direct molding production sheet is used to manufacture machine pads, roadbed pads, cushion pads and other types of gaskets, as well as mudguards, sound-absorbing materials and other low-end products that do not require high mechanical properties.

2. Colored elastic floor tiles are made of rubber powder rubber particles regenerated from waste rubber after cleaning, disinfection and processing. They are pressed by a double-layer structure. The bottom layer is the base and the surface layer is colored. The layers are distinct and integrated. They are functional and It is decorative, which overcomes the shortcomings of hard-textured bricks, and enables users to always be in a safe and comfortable physical and psychological state when walking or moving, with comfortable feet and relaxing body and mind.

3. Production of waterproof coiled materials, waterproof coatings, waterproof sealing materials and other waterproof building materials. The special rubber powder for waterproof coiled materials has good mixing performance with other raw materials such as asphalt and resin. The manufactured waterproof coiled materials have excellent aging resistance and good mechanical properties. , Cold flexibility and light stability.

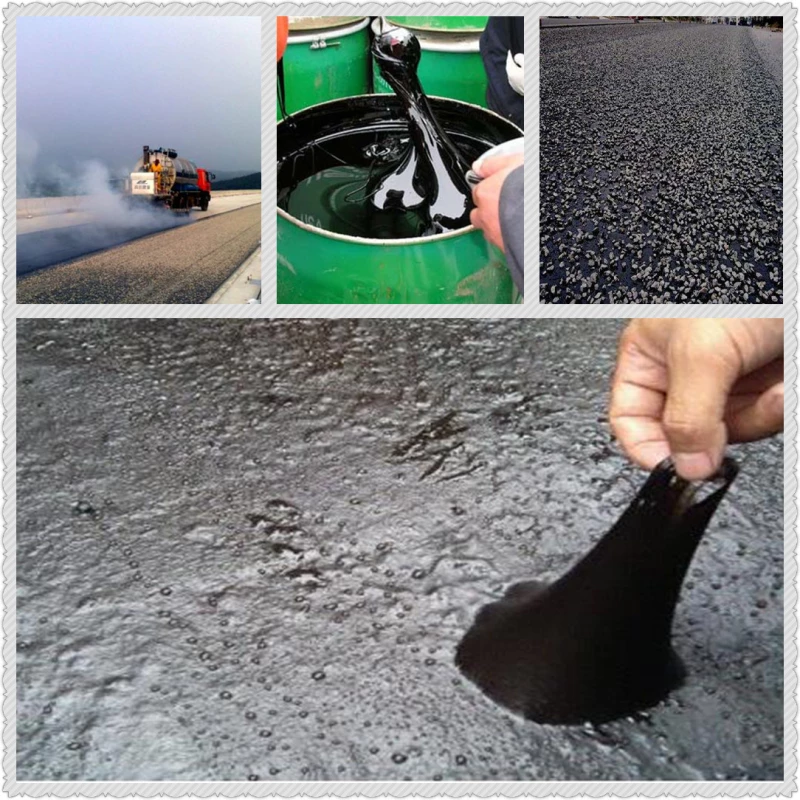

4. The use of rubber powder modified asphalt for road paving materials to pave high-grade highways and airstrips has entered the practical stage in developed countries and has been rapidly developed. Because the rubber powder contains antioxidants, it can significantly slow down the aging of the road surface, make the road surface elastic, reduce noise, and the road surface has abrasion resistance, water spalling resistance, and abrasion life 2-3 times that of ordinary roads. The maintenance cost of the road surface is reduced, and the braking distance of the vehicle is shortened by 25%, which improves the safety.

5. Used for Modified Asphalt When using asphalt modified rubber powder to make modified asphalt, it has good blending and combination with asphalt, asphalt oil, and coagulant. The abrasion resistance and peeling resistance of the pavement paved by the manufactured modified asphalt are greatly improved, and the abrasion resistance life is 2-3 times that of ordinary pavements, and the maintenance cost of the pavement is reduced by 30-50%. According to the test: after 5 years of use with 8,000 vehicles per day, there is no whitening, softness, crowding and cracking, and the braking distance of the vehicle can be shortened by 25%, which can significantly improve driving safety. The asphalt caulking ointment made with this product effectively increases the softening point of the product and increases the low temperature extensibility.

6. It can be directly extruded after mixing with plastics in a certain proportion for modified plastics. Experiments: the mixing and extrusion process performance of the modified plastic is improved; the applicability of the product is greatly improved.

7. Used to construct plastic sports fields, runways and artificial turf. The current usage is increasing exponentially.

8. It is used in oilfields to plug leaks and solid walls. In practice, it has good bonding performance with other bonding and aggregate materials.

9. It is used to add concrete to railway tracks before adding prefabricated mixtures, adding various high-grade concrete products that need to be added in a certain proportion, and casting directly. At present, it is used to manufacture railway tracks, isolation walls for special occasions, and foundations for special occasions.

10. High-grade highway caulking paste.

Add: Jingsan Road, Zhengzhou 450008, China

Tel/Mob/Wechat:+86-13213087830

Email: sinoaca@139.com

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.