Horizontal form fill seal packing machine for pharmaceutical powder, pesticide powder, salt, liquid product

|

Parameter |

UN-110 |

UN-130 |

UN-180 |

UN-180D(T) |

|

Bag Min size(W*H) |

50*70mm |

60*80mm |

75×85mm |

70×90mm |

|

Bag Max size(W*H) |

110*130 |

130*180 |

180×225mm |

90×180mm |

|

Bag volume |

70 ml |

200ml |

400ml |

100ml |

|

Machine Speed |

≤60 bag/m |

≤60 bag/m |

≤60 bag/m |

≤100 bag/m |

|

film thickness |

60-180μ |

60-180μ |

60-180μ |

60-180μ |

|

Outer roll diameter |

500㎜ |

500㎜ |

500㎜ |

500㎜ |

|

Inner roll diameter |

70-80㎜ |

70-80㎜ |

70-80㎜ |

70-80㎜ |

|

Machine dimension |

2650*970*1450 |

3000*970*1450 |

3500×970×1450 |

4850×1000×1450 |

|

Machine weight |

700 kg |

800kg |

900kg |

2000kg |

|

Room temperature |

-10℃—+55℃ |

-10℃—+55℃ |

-10℃—+55℃ |

-10℃—+55℃ |

|

Volt |

AC380V、50Hz |

AC380V、50Hz |

AC380V、50Hz |

AC380V、50Hz |

|

work air pressure |

0.6Mpa |

0.6Mpa |

0.6Mpa |

0.6Mpa |

|

air consumption |

200L/min |

200L/min |

200L/min |

600L/min |

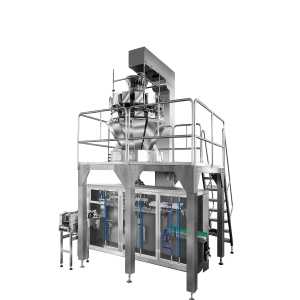

Product Description:

It is an ideal bag packaging equipment that meets the requirements of high-quality packaging and small bags, with fast packaging speed, and can be sealed on three sides and four sides: suitable for powder, particle, liquid, paste, solid and other material packaging requirements.

The machine includes film release structure, film drawing mechanism, bag forming mechanism, shear structure, filling mechanism, heat sealing, cold sealing shaping and other mechanisms.Under the programmable control of PLC, the integrated automatic production function of bag-making "open bag" detection "filling" and "sealing" finished product output is realized

Bag Application

Option Filler Device

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.