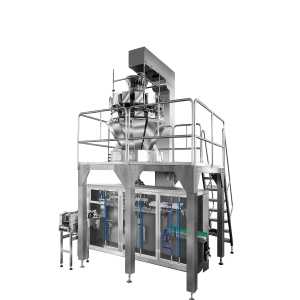

4 Nozzle Track Piston Filling Machines

- Filling Nozzel

- 4

- Filling Range(L)

- 1-5

- Filling Speed(BPH)

- 3000

- Voltage(V/HZ)

- 220/50

- Power(kW)

- 2.8

- Air Pressure(MPa)

- 0.4-0.6

- Dimension(mm)

- 4000×1350×2100

- Weight(Kg)

- 1000

Functional Features:

1) Fast machine adjustment: the speed of changing bottle-type products is fast, and it has the function of saving formula. After saving parameters, one button can complete the machine adjustment, which is very convenient and practical to save time.

2) A wide range of bottle types: as long as all kinds of special-shaped bottles standing on the line and vertically upward are also applicable, without special adjustment, the bottles can be put up and transported at will, which can greatly reduce the labor intensity of workers.

3) Double head up and down movement filling, effectively prevent foam formation.

4) The filling accuracy can reach ±1%. The metering cylinder body is treated by hard chromium and internal grinding, combined with the unique rotary valve design, accurate measurement, no leakage.

5) Sensor monitoring, no bottle, no canning, bottle accumulation automatic stop function.

6) The material contact part of the equipment adopts a live connecting mechanism, which can be disassembled and assembled without the help of any tools, so it is more convenient to clean.

7) The whole machine is made of 304 stainless steel (metal wire drawing panel), and the aluminum-magnesium alloy parts are anodized, which has the advantages of strong wear resistance, good insulation, strong corrosion resistance and so on.

8) This machine can store 8 groups of bottle data, change the bottle type only need to choose which group of parameters, the machine can automatically adjust according to the data; to achieve one-button adjustment, intelligent and efficient.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.