Essential Guide to Other Hand Tools for Every Workshop

When it comes to completing tasks efficiently in any workshop or job site, having the right Other Hand Tools is crucial. These tools, often overlooked, can make a significant difference in productivity and precision. Whether you're a professional tradesperson or a DIY enthusiast, understanding the various types, features, and applications of these tools will help you make informed purchasing decisions.

How to Find Reliable Other Hand Tools from China in 2025

China remains a leading manufacturer of high-quality Other Hand Tools, offering competitive prices and a wide range of options. To find reliable suppliers, consider platforms like Alibaba, which vet manufacturers and provide customer reviews. Look for suppliers with certifications such as ISO 9001, which ensures quality control. Additionally, request samples to test the tools before placing bulk orders.

What Buyers Should Know Before Buying Other Hand Tools from China

Before purchasing Other Hand Tools from China, buyers should be aware of shipping costs, import duties, and lead times. It's also essential to verify the supplier's reputation and read customer feedback. Ensure the tools meet international safety standards and come with warranties. Communication with the supplier is key to avoiding misunderstandings about specifications and delivery timelines.

Types of Other Hand Tools

There are several types of Other Hand Tools, each designed for specific tasks. Common categories include:

- Clamps and Vises: Used for holding materials securely during work.

- Files and Rasps: Ideal for shaping and smoothing surfaces.

- Punches and Chisels: Essential for making precise holes and cuts.

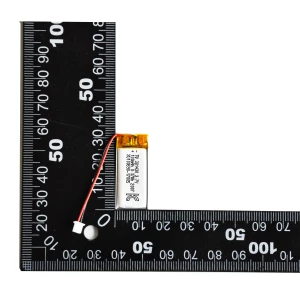

- Measuring Tools: Include calipers and rulers for accurate measurements.

- Striking Tools: Such as mallets and hammers for forceful applications.

Functions and features of Other Hand Tools

Other Hand Tools are designed to perform specific functions with precision and durability. Key features to look for include ergonomic handles for comfort, high-quality materials like carbon steel for longevity, and anti-corrosion coatings for extended use. Some tools also come with adjustable settings to enhance versatility.

Scenarios of Other Hand Tools

These tools are indispensable in various scenarios, from woodworking and metalworking to automotive repair and construction. For example, clamps are vital in carpentry for securing joints, while punches are crucial in metal fabrication for marking drill points. Understanding the right tool for the job can save time and improve results.

How to Choose Other Hand Tools

Selecting the right Other Hand Tools depends on the task at hand. Consider the material you'll be working with, the required precision, and the tool's durability. Opt for tools with comfortable grips to reduce fatigue during prolonged use. Additionally, check for warranties and after-sales support to ensure long-term satisfaction.

Other Hand Tools Q & A

Q: What are the most durable materials for Other Hand Tools?

A: Carbon steel and chromium-vanadium alloys are among the most durable materials, offering strength and resistance to wear.

Q: How can I verify the quality of tools from Chinese suppliers?

A: Request product certifications, read customer reviews, and order samples to test the tools before committing to a large purchase.

Q: Are there eco-friendly options for Other Hand Tools?

A: Yes, some manufacturers offer tools made from recycled materials or with eco-friendly coatings.

Q: What’s the average lifespan of high-quality Other Hand Tools?

A: With proper maintenance, high-quality tools can last for decades, even with regular use.

Q: Can I customize Other Hand Tools for specific needs?

A: Many suppliers offer customization options, including sizes, materials, and handles, to meet unique requirements.