Seals: A Comprehensive Guide for Buyers in 2025

Seals are essential components in various industries, ensuring the efficiency and longevity of machinery and equipment. Whether you're in manufacturing, automotive, or construction, understanding the different types of seals and their applications can help you make informed purchasing decisions. This guide covers everything from how to find reliable seal suppliers in China to the key factors to consider before buying.

How to Find Reliable Seals from China in 2025

China remains a leading supplier of high-quality seals, offering competitive prices and a wide range of options. To find reliable suppliers, start by researching manufacturers on platforms like Alibaba, where you can compare products, read reviews, and verify certifications. Look for suppliers with a proven track record, such as those with Gold Supplier status or ISO certifications. Additionally, request samples to test the quality before placing bulk orders.

What Buyers Should Know Before Buying Seals from China

Before purchasing seals from China, consider factors like material quality, customization options, and lead times. Ensure the supplier uses durable materials like nitrile rubber or silicone, depending on your application. Discuss customization needs, such as size or color, and confirm production and shipping timelines to avoid delays. It's also wise to negotiate pricing and payment terms to secure the best deal.

Types of Seals

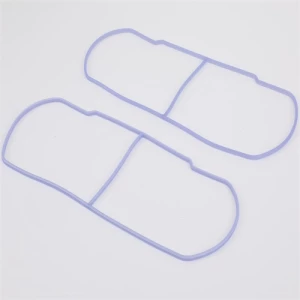

Seals come in various types, each designed for specific applications. Common types include:

- O-Rings: Used for static and dynamic sealing in hydraulic and pneumatic systems.

- Gaskets: Ideal for sealing joints between two surfaces, such as in pipelines.

- Lip Seals: Designed to prevent lubricant leakage in rotating shafts.

- Mechanical Seals: Used in pumps and compressors to prevent fluid leakage.

Functions and Features of Seals

Seals play a critical role in preventing leaks, reducing friction, and protecting machinery from contaminants. Key features to look for include:

- Durability: Resistant to wear, temperature extremes, and chemicals.

- Flexibility: Adapts to varying pressures and movements.

- Compatibility: Suitable for specific fluids or environments.

Scenarios of Seals

Seals are used across industries, including:

- Automotive: Engine components, transmissions, and fuel systems.

- Manufacturing: Hydraulic systems and machinery.

- Construction: Heavy equipment and pipelines.

How to Choose Seals

Selecting the right seal involves evaluating:

- Application Requirements: Consider pressure, temperature, and fluid compatibility.

- Material: Choose based on environmental conditions.

- Size and Design: Ensure a proper fit for your equipment.

Seals Q & A

Q: How do I know if a seal is high quality?

A: Look for certifications like ISO 9001 and request material test reports.

Q: Can I customize seals for specific needs?

A: Yes, many suppliers offer customization for size, material, and design.

Q: What is the typical lead time for orders from China?

A: Lead times vary but generally range from 2-6 weeks, depending on order size.

Q: How do I maintain seals to extend their lifespan?

A: Regularly inspect for wear, clean surfaces, and replace seals as needed.

Q: Are Chinese seals reliable for industrial use?

A: Yes, many Chinese manufacturers produce high-quality seals that meet international standards.