Seals: Essential Tools for Industrial and Home Applications

Seals are critical components in both industrial and home improvement projects, ensuring durability and efficiency. Whether you're working on machinery or household repairs, understanding the right type of seal can save time and money. This guide covers everything from types to selection tips.

How to Find Reliable Seals from China in 2025

China remains a leading supplier of high-quality seals. To find reliable manufacturers, check certifications like ISO 9001, read customer reviews, and request samples. Platforms like Alibaba offer verified suppliers with detailed product descriptions.

What Buyers Should Know Before Buying Seals from China

Before purchasing, consider material compatibility, load capacity, and environmental conditions. Always verify supplier credibility and negotiate bulk pricing for cost savings. Shipping times and customs regulations are also key factors.

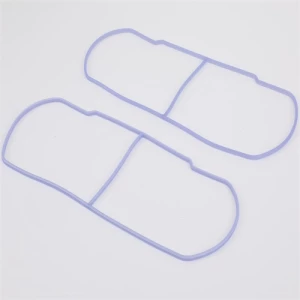

Types of Seals

Common types include O-rings, gaskets, and lip seals. Each serves a unique purpose, from preventing leaks in pipes to ensuring smooth machinery operation. Material choices range from rubber to silicone, depending on the application.

Functions and Features of Seals

Seals provide leak-proof connections, reduce friction, and extend equipment lifespan. Features like temperature resistance and chemical compatibility make them versatile for various industries, including automotive and plumbing.

Scenarios of Seals

From hydraulic systems to kitchen faucets, seals are everywhere. Industrial applications demand high-performance seals, while home projects often require cost-effective solutions. Understanding the scenario helps in selecting the right seal.

How to Choose Seals

Consider the operating environment, pressure requirements, and material durability. For example, silicone seals are ideal for high-temperature settings, while nitrile seals excel in oil-resistant applications.

Seals Q & A

Q: What is the lifespan of a typical seal?

A: Depending on material and usage, seals can last from a few months to several years. Regular maintenance can extend their lifespan.

Q: Are Chinese seals reliable?

A: Yes, many Chinese manufacturers produce high-quality seals that meet international standards. Always verify certifications and reviews.

Q: Can I reuse seals?

A: Some seals are reusable, but most are designed for single use to ensure optimal performance.

Q: How do I know if a seal is failing?

A: Signs include leaks, increased friction, or visible wear and tear. Replace seals immediately to prevent damage.

Q: What’s the difference between static and dynamic seals?

A: Static seals are used in non-moving parts, while dynamic seals are designed for moving components like shafts and pistons.