Best Pumps for Industrial and Home Use in 2025

Pumps are essential tools in various industries and households, serving multiple purposes from water supply to chemical processing. Whether you're looking for industrial-grade pumps or simple home solutions, understanding the types, features, and selection criteria is crucial. In this guide, we'll explore the best pumps available in 2025, how to source reliable options from China, and what to consider before making a purchase.

How to Find Reliable Pumps from China in 2025

China is a leading manufacturer of pumps, offering a wide range of options at competitive prices. To find reliable pumps from China, consider the following:

- Supplier Reputation: Check reviews and ratings on platforms like Alibaba to ensure the supplier has a good track record.

- Certifications: Look for ISO or CE certifications to guarantee quality and safety standards.

- Samples: Request samples to test the pump's performance before placing a bulk order.

- Customization: Many Chinese suppliers offer customization options to meet specific requirements.

What Buyers Should Know Before Buying Pumps from China

Purchasing pumps from China can be cost-effective, but buyers should be aware of potential challenges:

- Shipping Costs: Factor in shipping and import duties to avoid unexpected expenses.

- Lead Times: Production and shipping can take several weeks, so plan accordingly.

- Communication: Ensure clear communication with the supplier to avoid misunderstandings.

- Warranty: Verify the warranty terms to protect your investment.

Types of Pumps

Pumps come in various types, each designed for specific applications:

- Centrifugal Pumps: Ideal for transferring low-viscosity fluids like water.

- Diaphragm Pumps: Suitable for handling corrosive or abrasive fluids.

- Submersible Pumps: Used for draining water from basements or pools.

- Gear Pumps: Perfect for high-pressure applications like hydraulic systems.

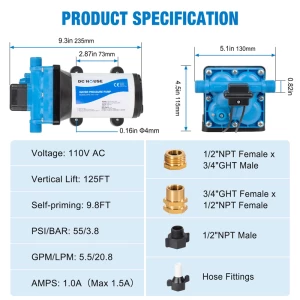

Functions and Features of Pumps

Modern pumps come with advanced features to enhance performance and durability:

- Energy Efficiency: Many pumps are designed to consume less power, reducing operational costs.

- Self-Priming: Some models can start pumping without manual priming.

- Corrosion Resistance: Stainless steel or coated materials prevent rust and extend lifespan.

- Smart Controls: IoT-enabled pumps allow remote monitoring and control.

Scenarios of Pumps

Pumps are used in diverse scenarios, including:

- Agriculture: Irrigation systems rely on pumps to distribute water efficiently.

- Manufacturing: Industrial pumps handle chemicals, oils, and other fluids.

- Home Use: Sump pumps prevent basement flooding, while booster pumps improve water pressure.

- Mining: Heavy-duty pumps are used to dewater mines and handle slurry.

How to Choose Pumps

Selecting the right pump depends on several factors:

- Flow Rate: Determine the required flow rate (gallons per minute) for your application.

- Head Pressure: Consider the height the pump needs to lift the fluid.

- Material: Choose materials compatible with the fluid being pumped.

- Maintenance: Opt for pumps with easy maintenance features to reduce downtime.

Pumps Q & A

Q: What is the lifespan of a typical pump?

A: Depending on usage and maintenance, pumps can last anywhere from 5 to 15 years.

Q: How do I know if my pump is failing?

A: Signs include reduced flow rate, unusual noises, and frequent overheating.

Q: Can I use a water pump for chemicals?

A: Only if the pump is specifically designed for chemical handling, as standard water pumps may corrode.

Q: What’s the difference between a centrifugal and a positive displacement pump?

A: Centrifugal pumps use rotational energy to move fluid, while positive displacement pumps trap and displace fixed amounts of fluid.

Q: How often should I service my pump?

A: Annual servicing is recommended, but high-usage pumps may need more frequent checks.