Everything You Need to Know About Cages for Power Transmission

Cages are essential components in power transmission systems, ensuring smooth operation and longevity of machinery. This article explores their types, features, and practical applications to help you make the right choice.

How to Find Reliable Cages from China in 2025

China remains a leading manufacturer of cages for power transmission. To find reliable suppliers:

- Verify certifications like ISO 9001

- Check customer reviews on Alibaba

- Request material test reports

- Ask for production capacity details

Top manufacturers often offer OEM services with minimum order quantities as low as 50 pieces.

What Buyers Should Know Before Buying Cages from China

When sourcing cages from China, consider:

- Lead times (typically 15-30 days)

- Shipping costs and import duties

- Payment terms (30% deposit is standard)

- Quality control processes

Always request samples before bulk orders to verify quality.

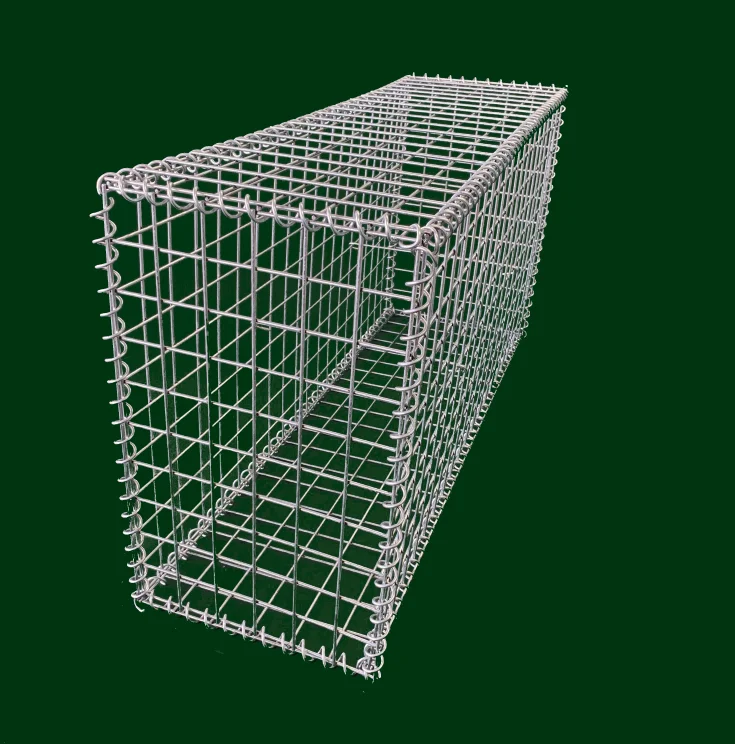

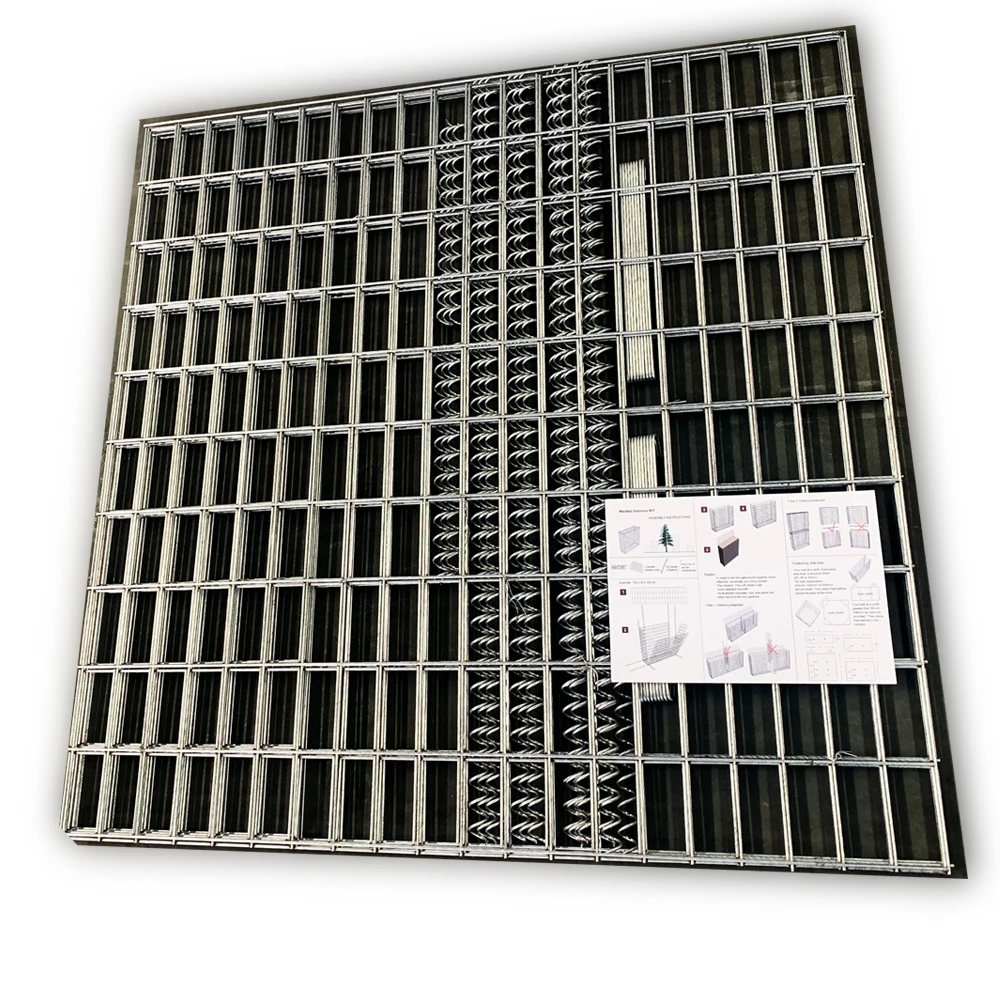

Types of Cages

Common cages include:

- Ball bearing cages: For high-speed applications

- Roller bearing cages: Handle heavier loads

- Polymer cages: Corrosion-resistant

- Steel cages: Maximum durability

Functions and Features of Cages

Cages perform critical functions:

- Maintain proper bearing element spacing

- Reduce friction and heat generation

- Prevent element contact during operation

- Extend bearing service life

Premium features include self-lubricating materials and noise reduction designs.

Scenarios of Cages

Cages are used in:

- Electric motors (60% of applications)

- Industrial gearboxes

- Automotive transmissions

- Wind turbine generators

A case study showed properly specified cages increased motor lifespan by 40%.

How to Choose Cages

Selection criteria:

- Match cage material to operating environment

- Consider speed requirements (RPM limits)

- Verify load capacity

- Check compatibility with bearing type

- Evaluate maintenance requirements

Cages Q & A

Q: What's the typical lifespan of a bearing cage?

A: 3-5 years in standard applications, but premium cages can last 7+ years.

Q: Can polymer cages handle high temperatures?

A: Special high-temp polymers work up to 250°C, beyond which steel is recommended.

Q: How do I know when to replace a cage?

A: Look for visible wear, increased vibration, or unusual noise during operation.

Q: Are Chinese cages comparable to European quality?

A: Many Chinese manufacturers now produce to ISO standards matching European quality at 30-50% lower cost.

Q: What's the cost difference between steel and polymer cages?

A: Polymer cages typically cost 20-30% less but may not suit all applications.