High-Quality Cages for Power Transmission

When it comes to power transmission systems, cages play a crucial role in ensuring smooth and efficient operations. Whether you're sourcing for industrial applications or specialized machinery, understanding the types, features, and buying considerations of cages is essential. This guide covers everything you need to know to make an informed decision.

How to Find Reliable Cages from China in 2025

China remains a leading supplier of industrial components, including high-quality cages. To find reliable manufacturers, consider these steps:

- Verify certifications like ISO 9001 to ensure quality standards.

- Check customer reviews and testimonials for credibility.

- Request samples to evaluate material and build quality.

- Compare pricing and lead times from multiple suppliers.

What Buyers Should Know Before Buying Cages from China

Before placing an order, buyers should be aware of:

- Material specifications (e.g., steel, aluminum, or composite).

- Customization options for unique industrial needs.

- Shipping and import regulations to avoid delays.

- After-sales support and warranty policies.

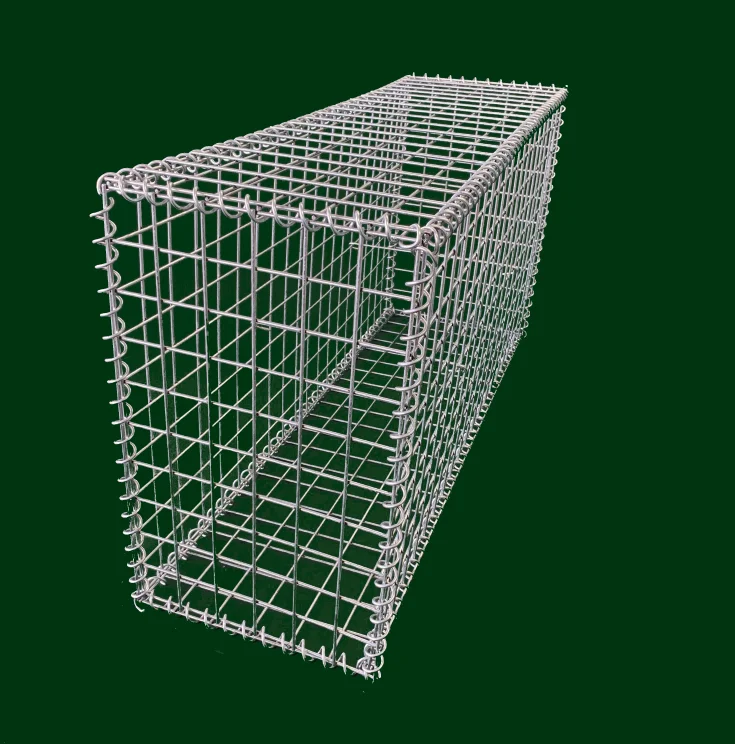

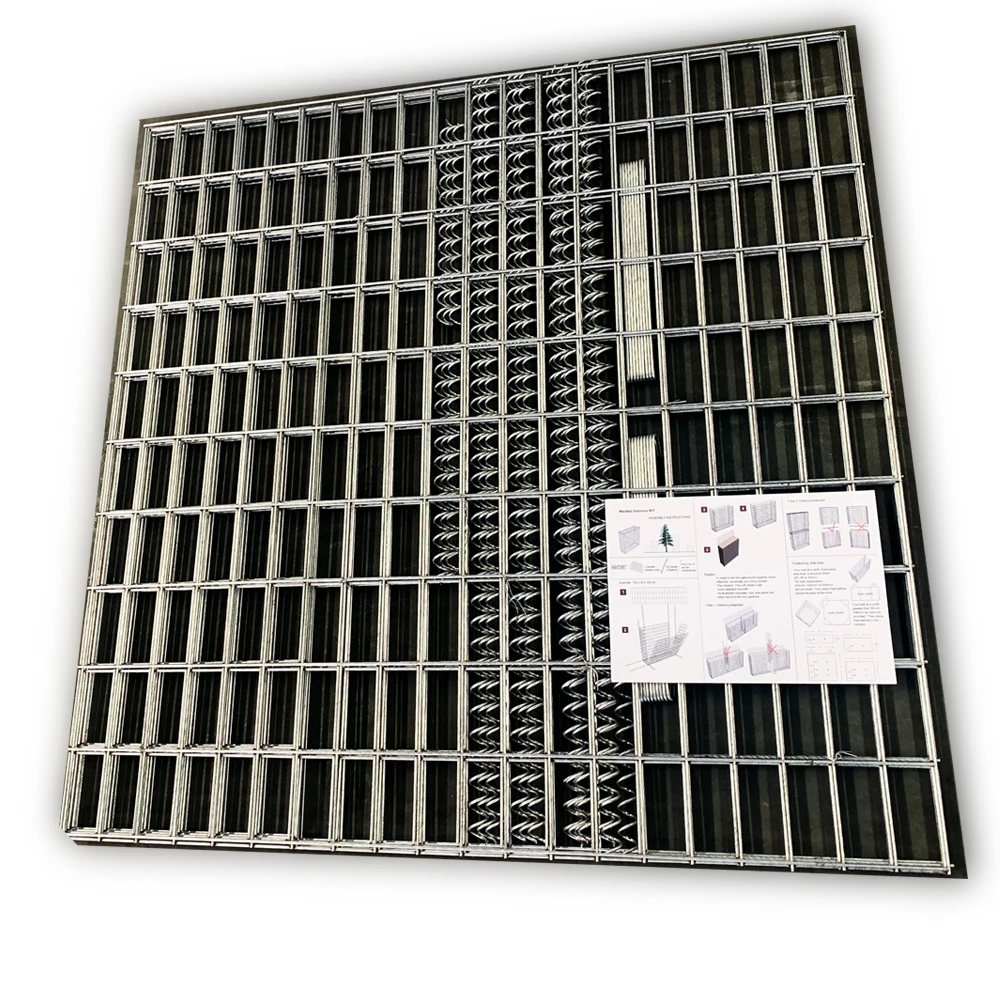

Types of Cages

Different applications require specific types of cages:

- Roller Cages: Ideal for high-load bearing systems.

- Ball Cages: Used in precision machinery for smooth motion.

- Composite Cages: Lightweight and corrosion-resistant.

- Custom Cages: Tailored for specialized industrial needs.

Functions and Features of Cages

Cages are designed to:

- Maintain alignment of rolling elements in bearings.

- Reduce friction and wear in power transmission systems.

- Enhance durability with high-grade materials.

- Support high-speed operations with minimal maintenance.

Scenarios of Cages

Common applications include:

- Automotive and aerospace industries.

- Heavy machinery and conveyor systems.

- Renewable energy equipment like wind turbines.

- Robotics and automation technology.

How to Choose Cages

Selecting the right cages involves:

- Assessing load capacity and operational speed.

- Choosing materials based on environmental conditions.

- Ensuring compatibility with existing systems.

- Prioritizing suppliers with proven track records.

Cages Q & A

Q: What materials are best for high-temperature applications?

A: Steel or ceramic cages are ideal for high-heat environments due to their thermal resistance.

Q: How do I maintain cages for longevity?

A: Regular lubrication and inspection for wear can significantly extend their lifespan.

Q: Can cages be customized for unique machinery?

A: Yes, many manufacturers offer bespoke solutions tailored to specific requirements.

Q: What’s the lead time for bulk orders from China?

A: Typically 4-6 weeks, but this can vary based on customization and supplier capacity.

Q: Are there eco-friendly cage options?

A: Composite and recycled material cages are available for sustainable operations.