Drill Bit Blanks: Your Ultimate Guide to Quality and Selection

When it comes to industrial tools and hardware, drill bit blanks are essential components for manufacturing high-performance drill bits. Whether you're a buyer, manufacturer, or DIY enthusiast, understanding the ins and outs of these blanks can help you make informed decisions. This guide covers everything from types and features to sourcing tips and FAQs.

How to Find Reliable Drill Bit Blanks from China in 2025

China remains a top supplier of drill bit blanks, offering competitive prices and a wide variety of options. To ensure reliability:

- Check supplier certifications like ISO 9001.

- Request samples to test quality before bulk orders.

- Read customer reviews and ratings on platforms like Alibaba.

- Verify material specifications (e.g., high-speed steel or carbide).

What Buyers Should Know Before Buying Drill Bit Blanks from China

Buying drill bit blanks from China requires due diligence. Key considerations include:

- Minimum Order Quantities (MOQs) and pricing tiers.

- Shipping and logistics costs.

- Customization options (e.g., coatings or special dimensions).

- Lead times and production capacity.

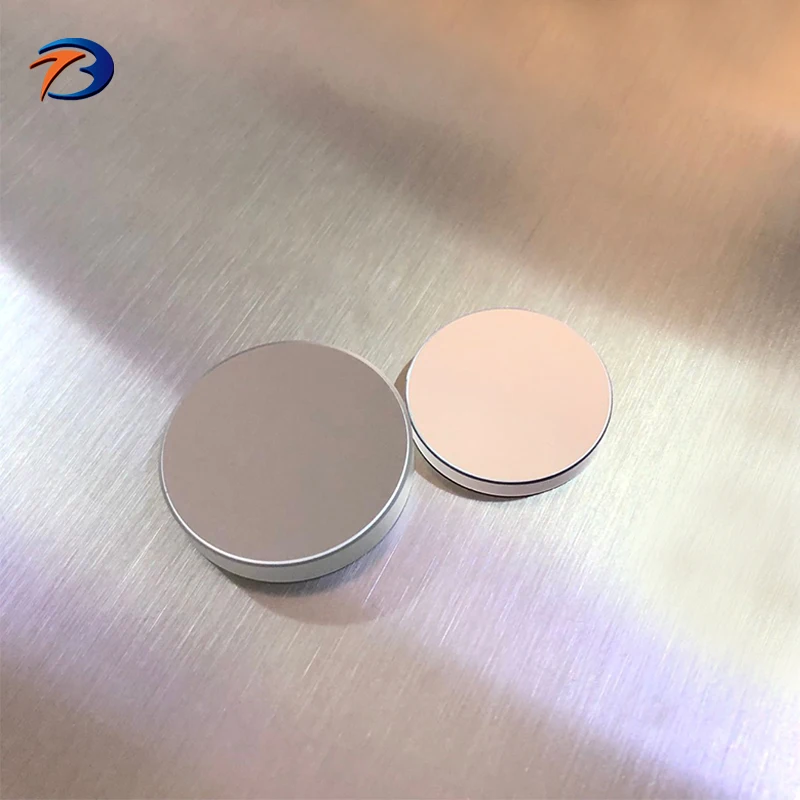

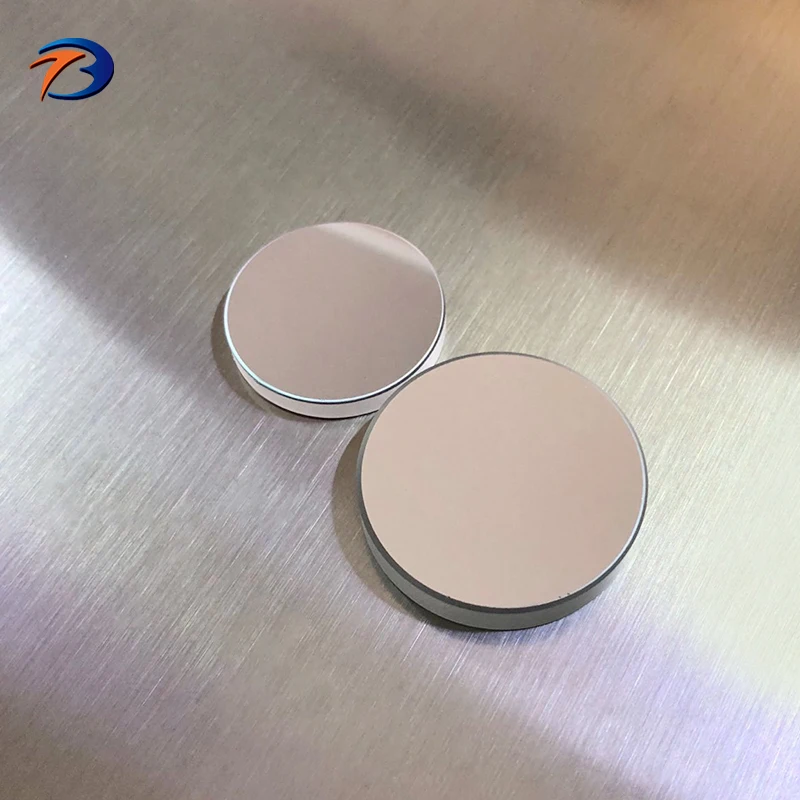

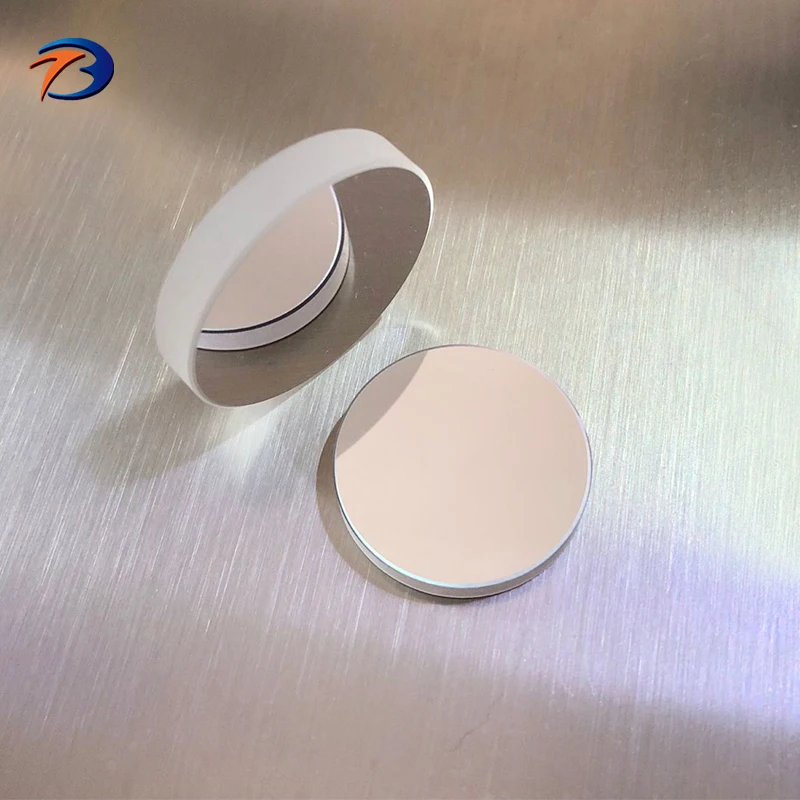

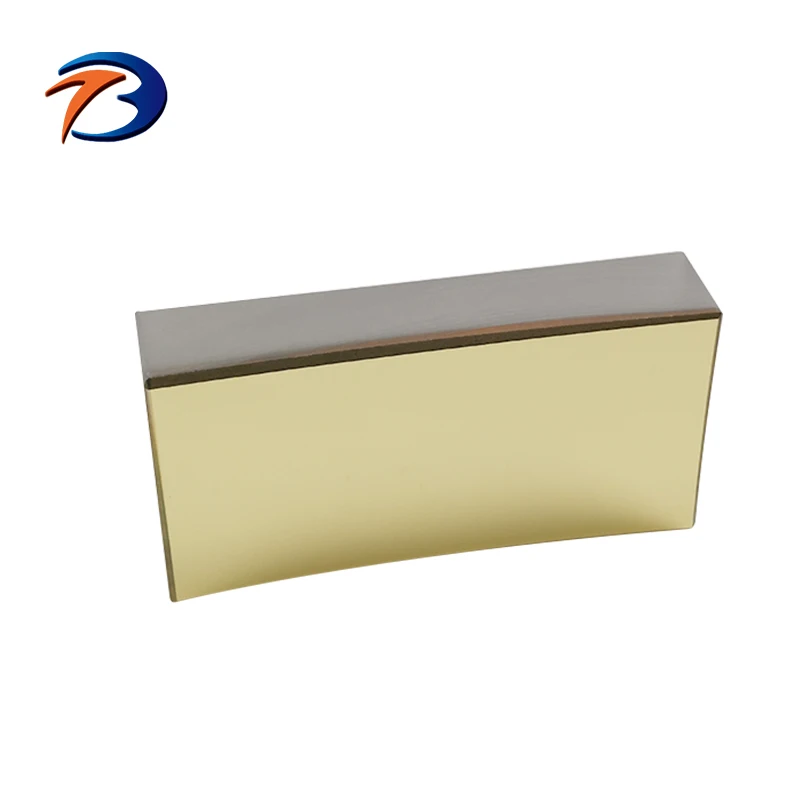

Types of Drill Bit Blanks

Drill bit blanks come in various materials and designs:

- High-Speed Steel (HSS): Affordable and versatile for general-purpose drilling.

- Carbide: Superior hardness and heat resistance for heavy-duty applications.

- Cobalt: Enhanced durability for tough materials like stainless steel.

- Diamond-Coated: Ideal for precision drilling in ceramics and glass.

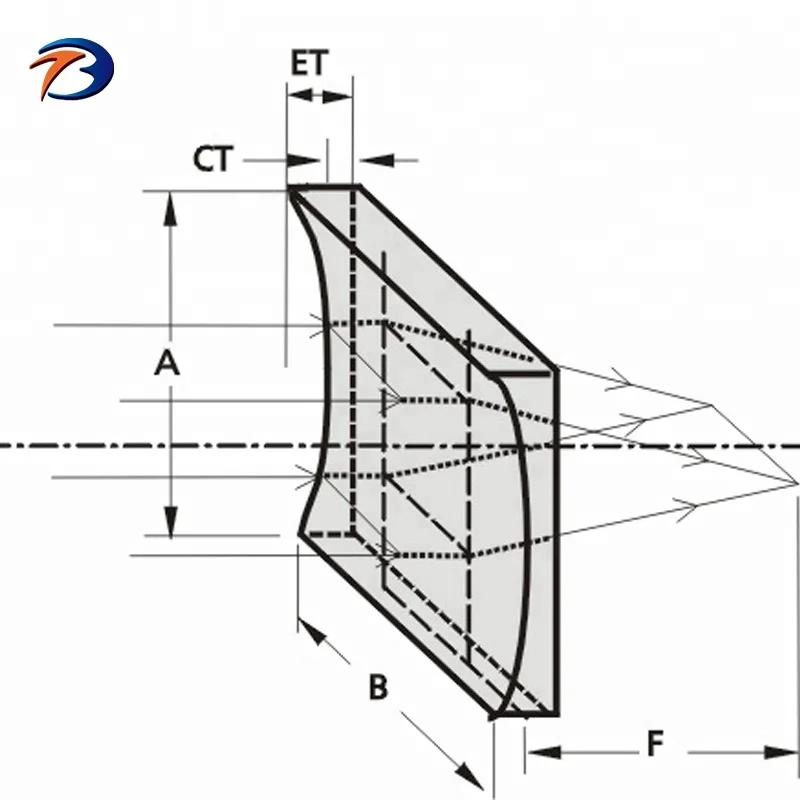

Functions and Features of Drill Bit Blanks

These blanks serve as the foundation for creating custom drill bits. Key features include:

- Precision-ground surfaces for accurate bit shaping.

- Heat-treated materials for extended tool life.

- Compatibility with CNC grinding machines.

- Customizable lengths and diameters.

Scenarios of Drill Bit Blanks

Drill bit blanks are used across industries:

- Automotive: Manufacturing engine components.

- Aerospace: Crafting precision parts.

- Construction: Creating masonry and wood drill bits.

- DIY Projects: Custom bit solutions for hobbyists.

How to Choose Drill Bit Blanks

Selecting the right blank depends on:

- Material: Match the blank to the workpiece (e.g., carbide for metals).

- Size: Ensure compatibility with your drilling equipment.

- Coating: Opt for coatings like TiN for reduced friction.

- Supplier Reputation: Prioritize vendors with proven track records.

Drill Bit Blanks Q & A

Q: What’s the difference between HSS and carbide blanks?

A: HSS is cost-effective for general use, while carbide excels in high-wear applications.

Q: Can I customize drill bit blanks?

A: Yes, many suppliers offer custom dimensions, coatings, and materials.

Q: How do I verify blank quality?

A: Request material certifications and conduct hardness tests.

Q: What’s the typical MOQ from Chinese suppliers?

A: MOQs vary but often start at 100–500 units for standard blanks.

Q: Are diamond-coated blanks worth the cost?

A: Only if drilling ultra-hard materials like glass or composites.