Transmission Belts: Your Guide to Sourcing and Selecting the Right Type

Transmission belts are essential components in power transmission systems, widely used in industries like automotive, manufacturing, and agriculture. Choosing the right belt ensures efficiency, durability, and cost-effectiveness. This guide covers types, functions, selection tips, and sourcing advice for buyers.

How to Find Reliable Transmission Belts from China in 2025

China remains a top supplier of transmission belts, offering competitive prices and quality. To find reliable manufacturers:

- Check certifications like ISO 9001 to ensure quality standards.

- Read customer reviews and request samples before bulk orders.

- Verify production capacity and lead times to avoid delays.

Platforms like Alibaba and Made-in-China list verified suppliers, making it easier to compare options.

What Buyers Should Know Before Buying Transmission Belts from China

Before purchasing, consider:

- Material quality: Rubber, polyurethane, and nylon are common. Ensure the material suits your application.

- Customization: Some suppliers offer tailored solutions for specific needs.

- Shipping costs: Factor in logistics to avoid unexpected expenses.

Negotiate MOQs (Minimum Order Quantities) and payment terms to align with your budget.

Types of Transmission Belts

Common transmission belts include:

- V-belts: Ideal for high-torque applications like industrial machinery.

- Timing belts: Used in engines for precise synchronization.

- Flat belts: Suitable for high-speed, low-power transmissions.

- Ribbed belts: Provide better grip and efficiency in automotive systems.

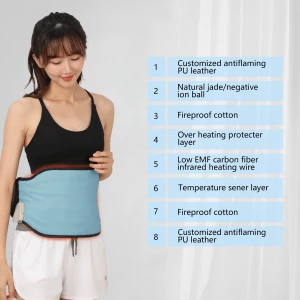

Functions and Features of Transmission Belts

These belts transfer power between shafts, ensuring smooth operation. Key features:

- Durability: Resistant to wear, heat, and chemicals.

- Flexibility: Adapts to pulley systems without slipping.

- Noise reduction: High-quality belts operate quietly.

Scenarios of Transmission Belts

Used in:

- Automotive: Timing belts in engines.

- Agriculture: Conveyor belts in harvesting equipment.

- Manufacturing: Powering assembly lines.

How to Choose Transmission Belts

Consider:

- Load capacity: Match the belt to your machinery's power requirements.

- Environment: Choose belts resistant to oils, heat, or moisture if needed.

- Size and fit: Ensure compatibility with existing pulleys.

Transmission Belts Q & A

Q: How long do transmission belts last?

A: Typically 50,000-100,000 miles in vehicles, but varies by usage and maintenance.

Q: Can I replace a transmission belt myself?

A: Yes, with basic tools, but consult a manual or professional for complex systems.

Q: What causes belt slippage?

A: Wear, improper tension, or misalignment. Regular inspections prevent this.

Q: Are Chinese transmission belts reliable?

A: Yes, many meet international standards. Always verify supplier credentials.

Q: How do I maintain transmission belts?

A: Keep them clean, check tension regularly, and replace if cracked or worn.