Cemented Carbide: The Ultimate Guide for Buyers in 2025

Cemented carbide is a high-performance material widely used in industrial applications due to its exceptional hardness and wear resistance. Whether you're in mining, manufacturing, or construction, understanding this material can help you make informed purchasing decisions. This guide covers everything from types and features to sourcing tips from China.

How to Find Reliable Cemented Carbide from China in 2025

China remains a leading supplier of cemented carbide, offering competitive pricing and high-quality products. To find reliable suppliers:

- Check certifications like ISO 9001 and RoHS compliance.

- Review supplier history and customer feedback on platforms like Alibaba.

- Request samples to test material quality before bulk orders.

- Negotiate MOQs (Minimum Order Quantities) and lead times.

What Buyers Should Know Before Buying Cemented Carbide from China

Before purchasing, consider:

- Material Composition: Ensure the product meets your required tungsten carbide (WC) and cobalt (Co) ratios.

- Customization Options: Some suppliers offer tailored solutions for specific applications.

- Logistics and Duties: Factor in shipping costs and import regulations.

Types of Cemented Carbide

Cemented carbide comes in various forms, including:

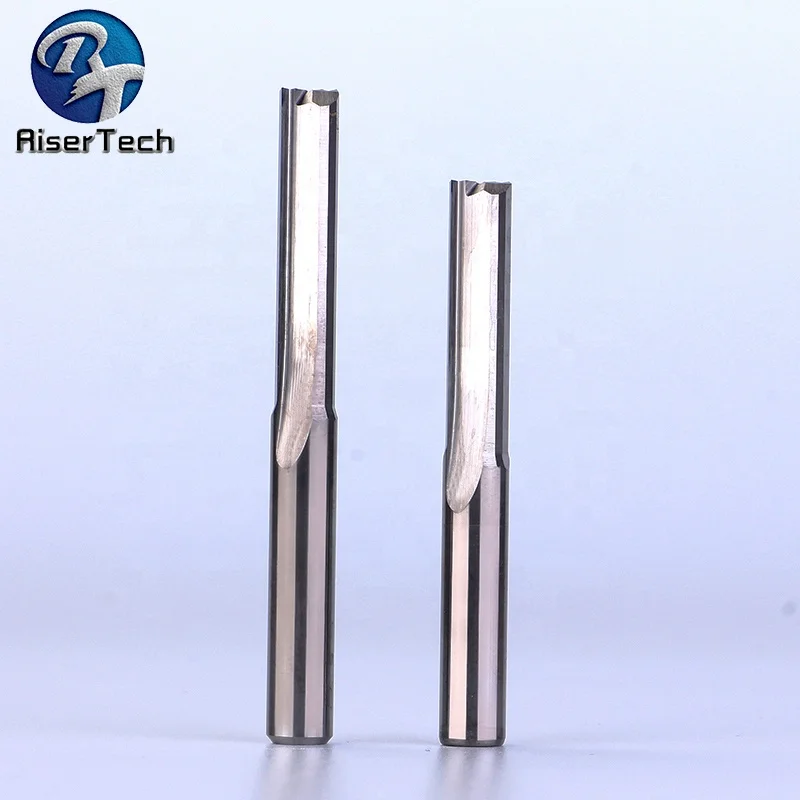

- WC-Co Alloys: The most common type, ideal for cutting tools and wear parts.

- WC-TiC-Co Alloys: Used in high-speed machining.

- Non-Magnetic Grades: Suitable for electronic applications.

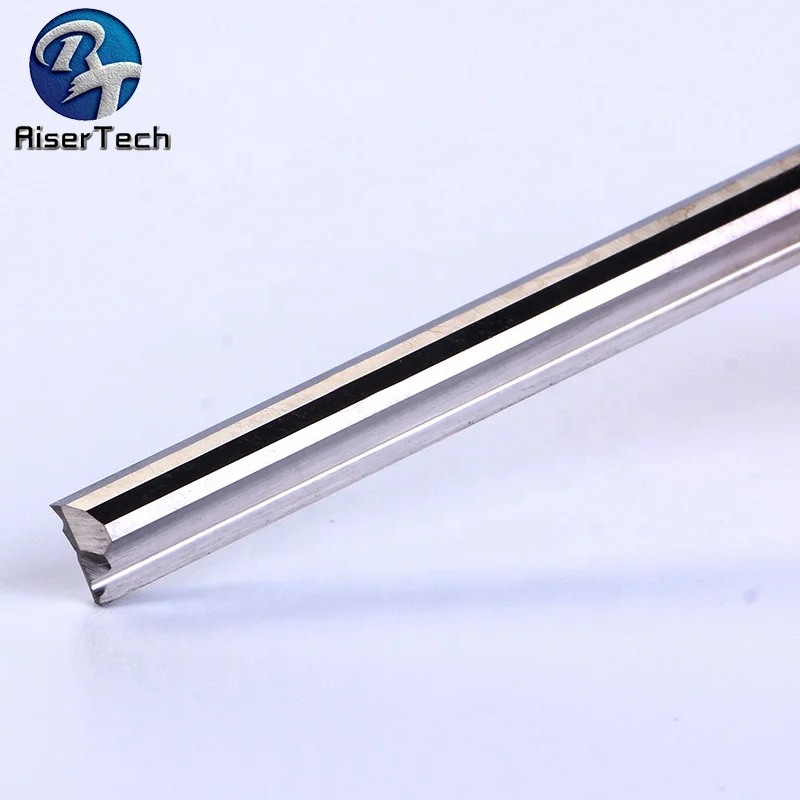

Functions and Features of Cemented Carbide

Key features include:

- High Hardness: Resistant to abrasion and deformation.

- Thermal Stability: Performs well under extreme temperatures.

- Corrosion Resistance: Ideal for harsh environments.

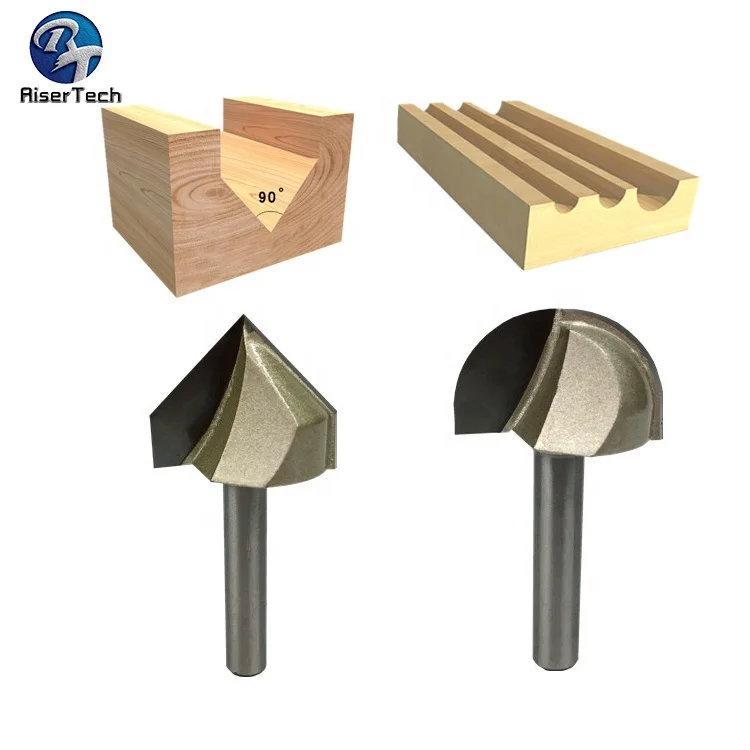

Scenarios of Cemented Carbide

Common applications:

- Mining Tools: Drill bits and cutting edges.

- Industrial Machinery: Inserts for lathes and milling machines.

- Construction: Wear-resistant components.

How to Choose Cemented Carbide

Selecting the right product depends on:

- Application Requirements: Match material properties to your needs.

- Budget: Balance cost with performance.

- Supplier Reputation: Opt for trusted manufacturers.

Cemented Carbide Q & A

Q: What is the typical lifespan of cemented carbide tools?

A: Depending on usage, they can last 5-10 times longer than traditional steel tools.

Q: How do I maintain cemented carbide products?

A: Regular cleaning and proper storage can extend their lifespan.

Q: Can cemented carbide be recycled?

A: Yes, it’s highly recyclable, reducing environmental impact.

Q: What’s the difference between cemented carbide and tungsten carbide?

A: Cemented carbide includes a binder (like cobalt), while tungsten carbide refers to the compound WC.

Q: Are there alternatives to cemented carbide?

A: Ceramics and polycrystalline diamond (PCD) are alternatives but may lack the same durability.