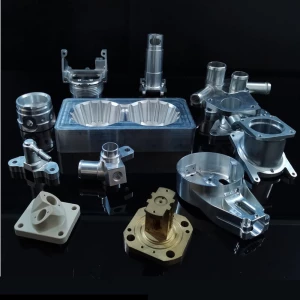

This process is used to produce a short production run or duplicated products, using the part produced via CNC, or SLA as a master to produce a silicone rubber mold. This silicone rubber mold is used in vacuum casting machine to produce accurate duplicate of original products. RTV equipment has several advantages including high production speeds, good accuracy (including the surface finish) and much lower costs. We are able to duplicate the product in a range of different materials, ABS, clear PC, PMMA, PP, PA simulant, etc.

We have 4 Vacuum Machines with a maximum size of 1200mmx800mmx800mm

Silicone tool – liquid silicone is poured around the master model and cured. Once dry the master is cut from the mold to leave the cavity

Castings – the resin is poured into the cavity to create a production like replica

Advantages of Vacuum Casting

Great for low volumes

Self-coloured parts

Low upfront investment

Production like parts

Massive range of materials

Rubber like parts and over molds

Used for

Low volume prototypes, low volume production, rubber parts, market testing, rapid iterations

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.