Turn Key Project Full Automatic Small Scale Beer Bottling Filling Packing Machine/Equipment Plant Line

Glass Bottle Filling Machine

500 to 24000BPH@330ml

PET Bottle Filling Machine

1000 to 40000BPH@500ml

Can Filling Machine

400 to 20000CPH@330ml

5 Gallon Water Filling Machine

100 to 1200BPH@3-5 Gallon

Manual Bottle Filling Machine

150 to 250BPH@330ml

Whole Beer Bottle Filling and Packing Line

1. Monoblock

2. Automatic Washing

3. Automatic Filling

4. Automatic Capping

5. Sterilization

6. Bottle Dryer Machine

7. Adhesive Labeling Machine

8. Date and Batch Coding Machine

9. Case Packing Machine

10. Case Sealing Machine

11. Working Table

12. Collection Table

13. Brewing Equipment

14. CIP Washer

15. Compressor Station

Kynhor Beer Bottle Filling Machine/Craft Beer Bottle Filler(Washing Filling Capping 3 in 1)

Kynhor Beer filling machine is designed for filling all kinds of beer and alcoholic beverages .

Automatic washing machines

1. Safety and hygiene : Stainless steel 304/316L for all components

2. Latest water-saving technology : Saving 30% water consumption

3. Latest Machine Structure : Avoid large amount of water accumulation inside the machine structure

4. Strong and Durable

5. The latest drainage design will not accumulate water

Automatic filling machines

1. 2 times vacuum, 2 times CO2 injection

2. No bottle , no filling

3. Stainless Steel 304/316 high precision filling nozzle

4. Level height can be adjusted , bought from Nanjing , the best valve in China

5. Efficient spray nozzle rinse throughly and save water for flushing

6. The latest drainage design will not accumulate water

Automatic capping machines

1. All 304/316 stainless steel construction

2. No bottle no capping

3. Automatic stop when lack of bottle

4. Capping effect is stable and reliable ,Defective rate ≤0.2% .

5. Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

6. The latest drainage design will not accumulate water

Automatic flat convey

1. Energy saving. High efficient. Adapt to customer factory layout

2. Special lubrication system, keep products clean, health, safety

3. Extended service life

4. Electric eyes design keep whole line running safety and quickly

5. Overload protection mechanism to effectively ensure the safety of the machine

Water treatment system.

1. Raw water tank + Raw water pump

2. Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3. Reverse Osmosis (one level)

4. UV sterilizer

5. Finished water tank + Pure water pump

Spray sterilization.

1. Mainly for bottle warming and sterilization

2. The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation

3. Nozzles are manufactured using U.S. technology and spray water evenly

4. Conveyor belt adopts Rexnor technology, flat surface with small wear

5. Smooth and reliable operation with low energy consumption

Adhesive labeling machine.

This machine adopts international advance technology; Stick the label on the Glass or PET bottle,And then fix on the position which bottle body designated.It is controlled by mirco-computer;automatic detection and position.

This machine's structure is compact,and suitanble for the production line of different direction and different height.

Bottle Packaging Machine.

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

CIP Washing System

The King Machine automatic machines and productions lines are equipped with necessary additional equipment for complex fulfillment of customer's technical tasks.

Shanghai Kynhor Machinery Co., Ltd.

1. Standardized workshop of total 8,000 square meters.

2. The equipment will be tested and run for more than 12 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

3. 2 Years Warranty and 2 Years Spare parts for free .

4. Go through Alibaba.com to ensure the timely delivery and the safety of your funds .

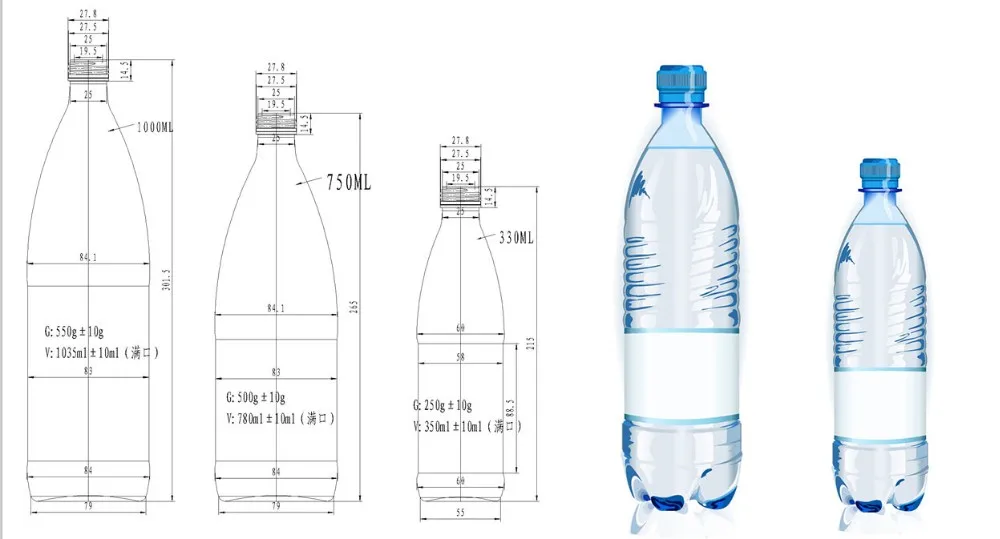

Bottle Design Drawing

Whole Production Line Layout Design Drawing

Turn Key Project

7*24 Hours Service

Q.1.ARE YOU A MANUFACTURER OR TRADING COMPANY?

● Kynhor is a manufacturer with trading company who is registered in the Chinese Business Administration and has the right to operate and sell it legally.

● Kynhor cooperates with Alibaba who will supply you a lot of service to protect you .

● Kynhor has a professional engineer team who all have more than 25 years experience in beverage filling machine manufacturing .

Q.2.HOW TO VISIT OUR FACTORY?

● If you are interested in our products, you may visit our factory at any time , we can pick you up from the station or the airport near our city .

● Seeing is believing , you can see our machine quality after your visit .

Q.3.HOW TO ENSURE THE MACHINE QUALITY?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Before shipping, the whole machine will run more than 12 hours to ensure the stable running in your factory

Q.4.HOW TO GUARANTEE YOUR FUNDS?

● We go through Alibaba.com Guarantee Service, which can protect your funds to be safe.

● We will send you pictures of the machine every week to ensure the delivery.

Q.5.KYNHOR MACHINE AFTER-SALE SERVICE

● We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

● When you finish the preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

● We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

● We provide 2 year warranty with spare parts free and life-long technical support .

Kynhor-Help Each Customer Make Professional Decision !

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.