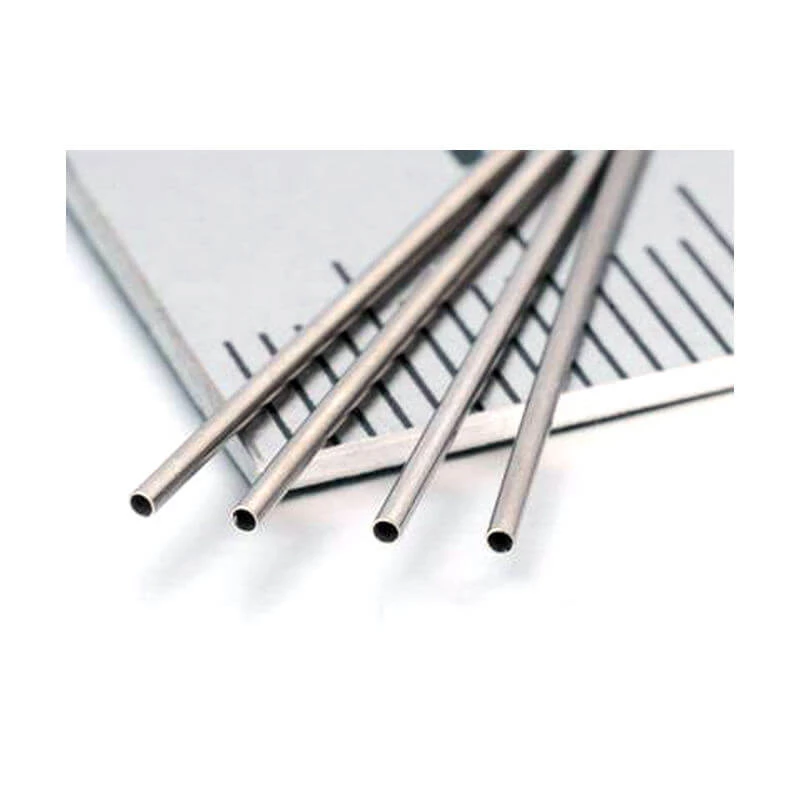

Titanium tubes have the feature of light weight, high strength and superior mechanical properties. Titanium tubes are widely used in heat-exchange equipment, such as tube type heat-exchanger,coiled type heat-exchanger,coil heat-exchanger, condensator,evaporator and transmission pipeline. Many nuclear power industry ues titanium tubes as the unit standard tubes.

| Product Name | Cp1 Cp2 seamless titanium tubes |

| Material | Pure titanium and Titanium alloy |

| Titanium Grade | Grade 1—Unalloyed titanium |

| Grade 2—Unalloyed titanium | |

| Grade 3—Unalloyed titanium | |

| Grade 7—Unalloyed titanium plus 0.12 to 0.25 %palladium | |

| Grade 9—Titanium alloy (3 % aluminum, 2.5 % vanadium) | |

| Grade 12—Titanium alloy (0.3 % molybdenum, 0.8 % nickel), | |

| Standard | ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862,AMS4911,AMS4928 |

| Shape | Round Square Rectangle |

| Type | Seamless/Welded |

| Processing | Seamless titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Bar billets—Extruding—Rolled—Straightening—Seamless tube |

| Welded titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Plate billets—Hot rolled—Cold rolled—Titanium scrap—Welded—Welded tube | |

| Surface | Polishing, picking, acid washed, black oxide |

| Application | 1) General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear |

| 2) Fluid, gas and oil transport | |

| 3) Pressure and heat transmission | |

| 4) Construction and ornament | |

| 5) Boiler heat exchangers | |

| 6) Motorbycle and bike | |

| Material Milling Certificate | According to. EN 10204.3.1 |

| Including Chemical composition and Mechanical property |

| Standard | ASTM B337, ASTM B338, ASTM B861, ASTM B862 |

| Specification | OD5.0-114.0mm x WT0.5-7.0mm x 1000-12000mm |

| OD55mm-914mm x WT1.0-10.0mm x 1000-6000mm | |

| Or according to customer’s requirement. | |

| Payment | T/T, L/C ,Paypal, as your inquiry |

| Technique | Rolled |

| Condition | Annealed(M) |

| Application | a) General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear) |

| b) Fluid, gas and oil transport | |

| c) Pressure and heat transmission | |

| d) Construction and ornament | |

| e) Boiler heat exchangers | |

| f) motorbycle and bike | |

| Certificate | ISO9001:2008, TUV, EN10204.3.1 |

| Mechanical Properties(>%) | |||||||

| Grade | Tensile Strength(min) | Yeild Strength(0.2% offset)) | Elongation(%) | ||||

| ksi | MPa | Min | Max | ||||

| Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 25 | 170 | 45 | 310 | 24 |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 9 | 90 | 620 | 70 | 483 | - | - | 15 |

| 12 | 70 | 483 | 50 | 345 | - | - | 18 |

Titanium tube uses

1. Aerospace field: The strength and toughness of titanium tubes can meet the high strength, high temperature, and high pressure requirements of aircraft, rockets, satellites, etc. Titanium tubes have excellent corrosion resistance and corrosion resistance and can be used to produce various structures and components, such as engine components, cylinders, landing gear, seat frames, oxygen bottles, rocket sealing structures, etc.

2. Marine engineering field: The water pressure in the depths of the ocean is huge, and corrosion-resistant materials have become a necessary condition for marine engineering. Titanium tubes are also widely used in this field, such as the production of submarine pipelines, submarine oil wells, support structures for marine wind turbines, and marine biological resource survey equipment.

3. Chemical industry: Titanium pipes have excellent corrosion resistance and high temperature resistance, and can withstand corrosion from various acids, alkalis, salts, oxidants, and high-temperature steam, water, gas and other media. In the chemical industry, titanium tubes are commonly used to produce various chemical equipment, such as evaporators, heat exchangers, reactors, catalytic converters, centrifuges, etc.

4. Medical field: Titanium tubes have good biocompatibility, are not likely to cause rejection in the human body, and have excellent corrosion resistance and strength. They have gradually become the material of choice in the medical field. Titanium tubes can be used to make medical devices such as artificial joints, dental implants, skull repair materials, and internal stents.

5. Sporting Goods: Titanium tubes have the characteristics of high strength, light weight, and corrosion resistance. They are very suitable as materials for making high-quality irons, golf clubs, bicycle frames and other sports equipment.

6. Other fields: In addition to the above fields, titanium tubes are also widely used in automobiles, textiles, electronics and other fields, such as automobile exhaust pipes, textile machinery parts, electronic component brackets, etc.

[Summary] Titanium tubes have excellent characteristics and are widely used in various fields such as aerospace, marine engineering, chemical industry, medical treatment, and sports. As technology continues to advance, the uses of titanium tubes will continue to expand.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.