Ti-13Nb-13Zr wire is a near β alloy formulated at the beginning of the 1990s to be used in orthopedic applications due to its low Young’s MODULUS (40-80 GPa) and its non-toxic composition. The main advantage of the Ti-13Nb-13Zr alloy, compared to other titanium alloys, such as Ti-6Al-4V and Ti-6Al-7Nb, widely used as biomaterials, is its low elasticity modulus, closer to that of bone, and the absence of aluminum and vanadium, which have been reported to cause long-term adverse effects. It presents tensile values of approximately 1300 MPa and superior corrosion resistance when compared to Ti-6Al-4V and Ti-6Al-7Nb.

| Standrd | ASTM F1713 |

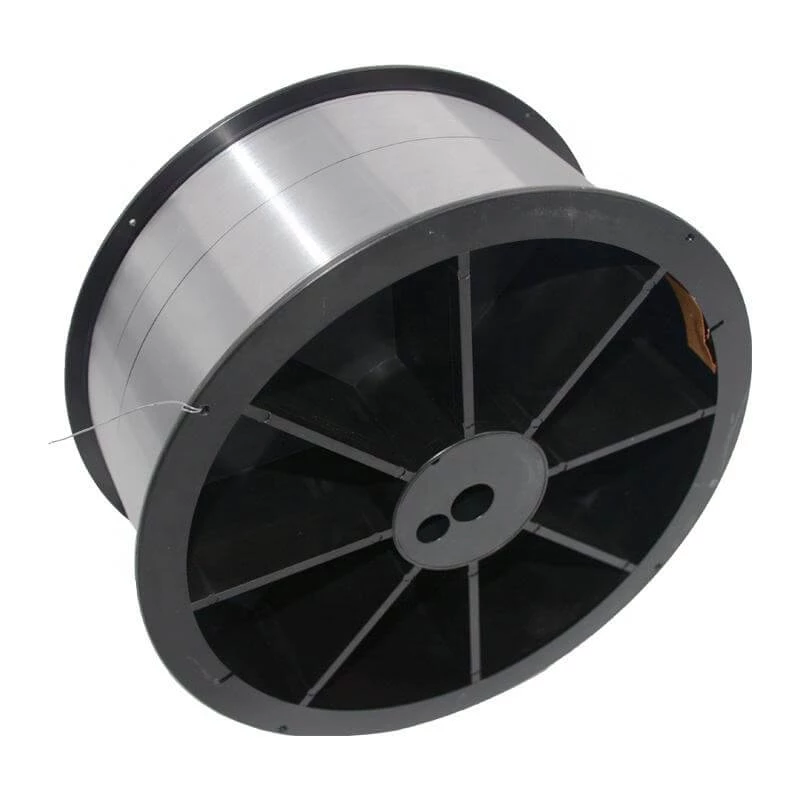

| Specification | Dia<4.76mm |

| Surface | Bright/pickling |

| Technique | Titanium spoonge-Compcating Electrode-Melting-Ingot-Forging-Finish Forging-Bar Billet-Forging--Wire Drawing-Wire-Inspection-Packing-Delivery |

| Application | Surgical implants |

Chemical Component of Ti-13Nb-13Zr Wire

| Grade | Nb | Zr | N(max) | C(max) | H(max) | Fe(max) | O(max) | Ti |

| Ti-13Nb-13Zr | 12.5-14.0 | 12.5-14.0 | 0.05 | 0.08 | 0.012 | 0.25 | 0.15 | Balance |

Mechanical Properties of Ti-13Nb-13Zr Wire

| Grade | Tensile strength,Mpa | Yield strength,MPa | Elongation, % | Reduction of Area,% (min) |

| Capability aged | 860 | 725 | 8 | 15 |

| Solution treated | 550 | 345 | 15 | 30 |

| Unannealed | 550 | 345 | 8 | 15 |

The main characteristics and applications of Ti-13Nb-13Zr wire:

Main features:

1. High strength and low modulus: Ti-13Nb-13Zr alloy possesses high tensile strength while maintaining a relatively low elastic modulus, which helps reduce stress shielding effects, especially in medical implant applications .

2. Excellent corrosion resistance: The alloy has high resistance to corrosion and can maintain stability even in extreme environments, such as chlorine-containing environments.

3. Biocompatibility: Due to its excellent biocompatibility, it will not cause adverse reactions to human tissues and is suitable for long-term implantation in the body.

4. Cold workability: The alloy can increase its strength through cold working and can be made into different shapes such as filaments.

5. Superelasticity: Some β-type titanium alloys exhibit superelastic behavior, that is, they are able to undergo a large amount of elastic deformation after external force is applied, and return to their original shape after the force is removed.

Application areas:

1. Medical implants: Mainly used to produce orthopedic implants, such as joint replacement devices, fracture internal fixators, and surgical needles and threads.

2. Dentistry: Used as dental implants and restorative materials.

3. Medical devices: Manufacture of various surgical tools and equipment, including those requiring high fatigue resistance and good plasticity.

4. Eyewear industry: used to make eyeglass frames with good elasticity, comfort and durability.

5. Sports equipment: In the field of sports equipment, such as golf heads and tennis racket strings, their lightweight and high-strength characteristics are utilized.

6. Aerospace: Although not as widely used in this industry as other specialty alloys, Ti-13Nb-13Zr can also be used to manufacture specific components, especially those requiring extreme reliability and durability.

7. Precision instruments: In precision engineering and instrument manufacturing, this alloy can be used to manufacture parts that require high precision and stability.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.