| Grades | RO5200, RO5400, RO5252, RO5255 |

| Standard | ASTM B365 |

| Size | Dia.: 0.1mm-5.0mm ( tolerance: +/-0.05mm ) |

| Condition | Hot rolled, Cold drawn, Annealed |

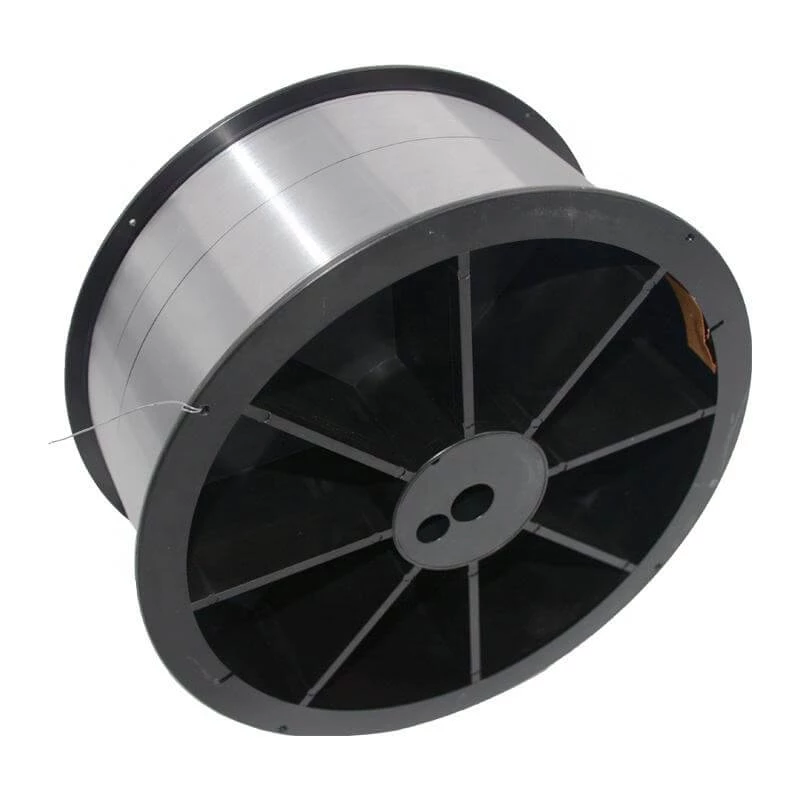

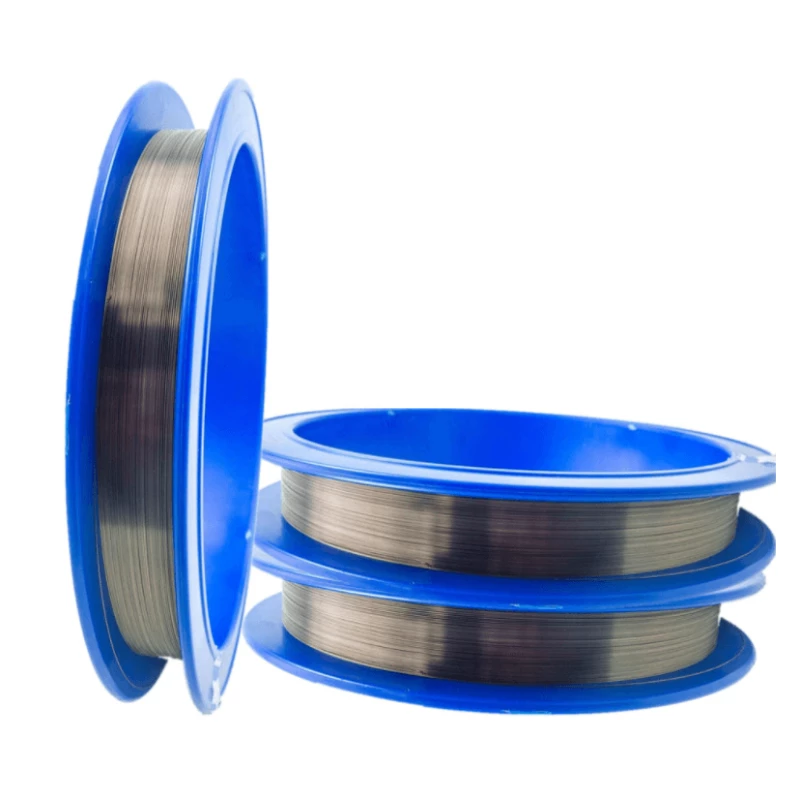

| Shape | Coils or Customers’ Requests |

| Surface | Black, Pickled, Polished ( For Dia. >1mm ) |

| Packing | Standard seaworthy packages or as your requests |

Tantalum exhibits high reactivity towards interstitials elements like Hydrogen, Nitrogen and Oxygen. Also it may react with Hydrocarbons. Its recrystallization temperature varies between 900 °C and 1450 °C. Vacuum and dry inert gases are most suitable as heat treatment atmospheres. The duration of the heat treatment may depend on the equipment, the process and the experience with the material. Lubricants should be completely removed prior to the heat treatment. If not, they may react with the Tantalum and cause embrittlement of the material.

Remark: Special requirements of tantalum wire will to be agreed on by the supplier and buyer of negotiations.

Applications:

Size

Material

Tantalum

Grade

Ta1,Ta2,TaW2.5,TaW7.5,TaW10,TaNb3,TaNb20,TaNb40

Purity

99.95%

Size

Different size are available

Application

Industrial, Electronic, Medical

Packaging

Standard export plywood case or as per order

Mechanical Property

Diameter mm

Ø0.10~Ø0.15

Ø0.15~Ø0.30

Ø0.30~Ø0.10

Tolerance

±0.006

±0.007

±0.008

Ovality

0.004

0.005

0.006

State

MPa

%

Mild (M)

300-750

10-30

Semihard(Y2)

750-1250

1-6

Hard(Y)

>1250

1-5

Tantalum wire is widely used in electronic industry. It is mainly used as anodic lead wire of tantalum electrolytic capacitor. Tantalum wire was the first material used for filaments in light bulbs. Tantalum wire is also used in the electronics industry in the manufacture of rectifiers and capacitors. Other applications include medical devices, chemical processing, and lighting applications. Whether in the cold and hot conditions, hydrochloric acid, concentrated nitric acid or in "aqua regia", tantalum wire has no chemical reaction. In medicine, tantalum is used to make flakes or sewing thread to mend the destructive tissue.

Specification

Manufacture Technique

1. Powder Metallurgic Method:

Tantalum powder---Mixing---Molding---Melting---Rotary Forging---Mid annealing---Drawing---Final Annealing---Inspecition---Packing

2. Melting Process Method:

Tantalum Powder---Mixing---Molding---Pre-sintering---Electron beam melting---Forging---Mid Annealing---Rotary Forging---Mid Annealing---Drawing---Final Annealing---Inspecition---Packing

Feature:

1. Good ductility

2. Small coefficient of thermal expansion

3. High temperature resistance

4. Good corrosion resistance

5. Good biological adaptation

Application

1.Solid electrolytic capacitor

2.Radar,aerospace, medical, biomedical, electronic,

3.Aircraft

4.Electronic computer

5.Heat exchanger, Heater, Evaporaator

6.Part of reactive tank

7.Electronic transmitting tube

8.Part of high temprature electronic tube

9.Bone plate for medical, bolt for medical, suture needles

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.