Standard automatic bottle shrink label sleeve trapping labeling machine

Product Description:

1.Whole machine use quantity of stainless steel and good-quality Aluminium alloy ,reasonable fracture,compact,convenient to adjust;

2.Shrinkage film volume label rack, match with adjustable device, convenient to adjust according to differ volume label 5″~10″paper tube.

3.Simply installation, then can convenient for square and round bottle.

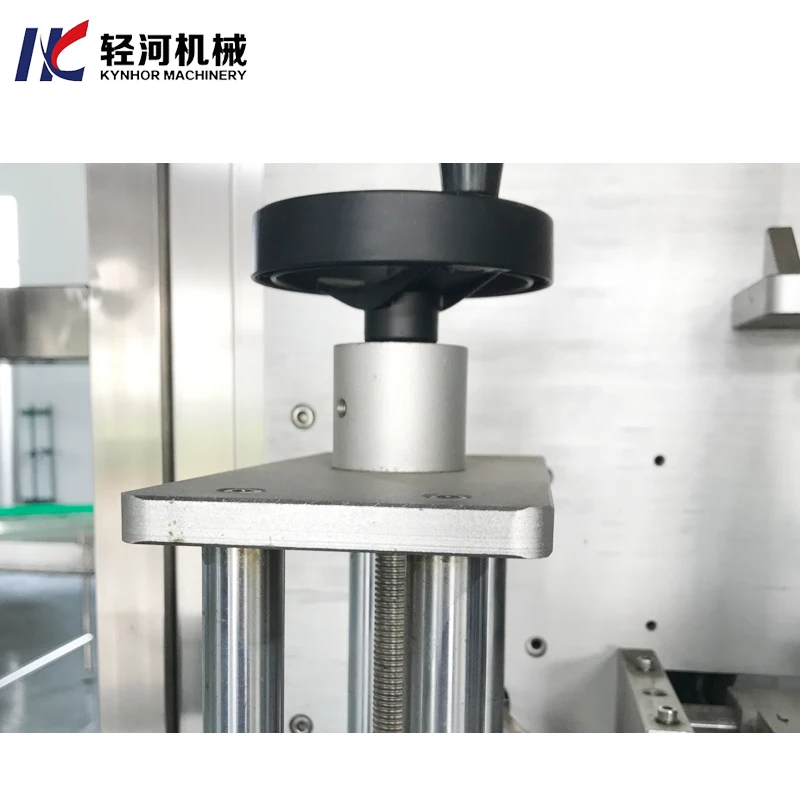

4.No need of instrument, rotary mechanism is convenient to adjust, apply to differ bottle type.

5.Unique sleeve labeling method, adopt to pressing sleeve labeling method, not only convenient but also reasonable.

6.Auto controlling feeding system, level-off shrinkage film materials .

7.Unique design knife plate, within specification scope, can avoid changing knife base.

8.Middle guide-pole clip system, mould changing is more quick, no need any instrument.

9.Label location system, can promote and adjust location according to specific bottle type requirement.

Our advantages:

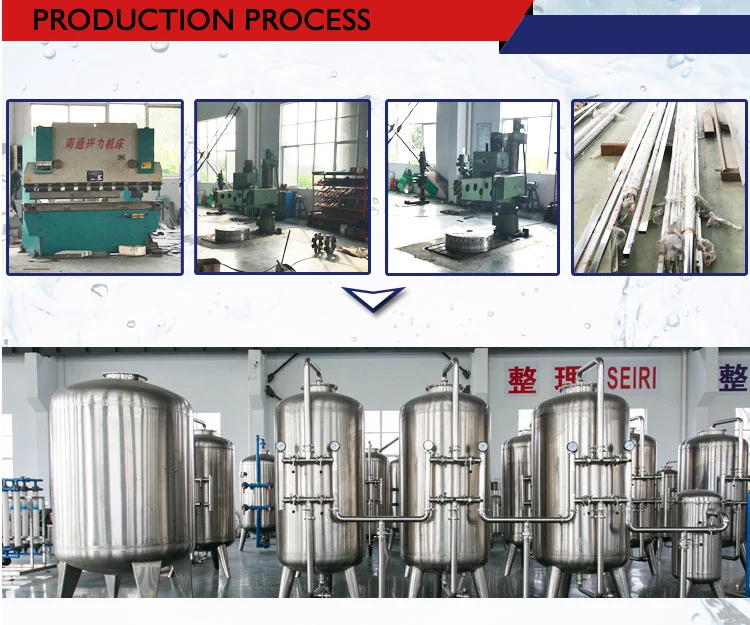

1.The high stability of the mechanical structure: the whole machine made of stainless steel and aluminum alloy frame cover protective rigid frame, solid does not rust.

2.More flexibility to choose the bottle: You can set round bottles, square bottles, elliptical bottle, bottle or bottle can also choose to set.

3.Highquality positioning accuracy: fully mechanical transmission design, the use of forced sets of standard, film thickness of various membrane materials 0.030MM above are applicable, the membrane material adjustable inner diameter of 5 - 10 range.

| Item | Technical data |

| Import Power | 3.0KW |

| Import Voltage | 3, 380/220 VAC |

| Capacity(production speed) | 400 bottles per min |

| Dimension of Host Machine (mm) | L2100× W850 × H2000 |

| Applicable Diameter Container (mm) | φ28 mm ~ φ120mm |

| Applicable Label Length (mm) | 30~250 mm |

| Applicable Thickness Label (mm) | 0.03~0.13 mm |

| Applicable Inner Diameter of Paper Tube | 5''~10'' |

How to trust us!

1.Kynhor cooperates with Alibaba who will supply you a lot of service to protect you .

2.Kynhor is registered in the Chinese business administration and has the right to operate and sell it legally.

3.Kynhor has a professional engineer team who all have more than 15 years experience in beverage filling machine manufacturing .

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station or the airport near our city.

3.If we get the permission of the customer who has brought the machines from us,we can tell you our customers' contact information,you can go to visit their factory.

4.We provide you with free debugging .

Customized service

1.We can design the machines according your requirements(material,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

2. We can offer free technical support and consultation such as design your factory,draw the factory layout and so on.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty with spare parts free and life-long technical support .

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.