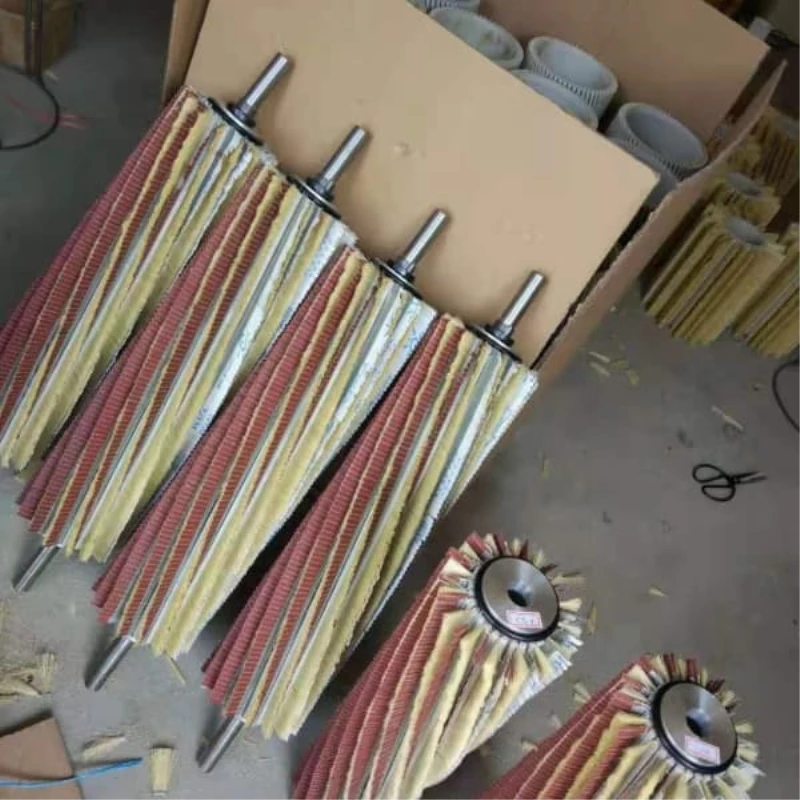

Sanding machine brush roller

- Length

- 300-1500

- Outer diameter

- 200-300

- Materials

- sisal and sandpaper

Other recommendations for your business

The sanding machine brush roller adopts advanced manufacturing technology and high-quality materials. The materials of its brushes are diverse, such as nylon, sisal, etc. These materials have good flexibility and wear resistance, and can tightly adhere to the surface of the processed material during the sanding process. Whether it is wood, metal or other materials, the sanding machine brush roller can achieve precise polishing effect, remove surface defects, burrs, etc., and achieve the ideal smoothness of the material surface.

During the sanding process, it is inevitable to produce some debris and dust. The special structure of the sanding machine brush roller not only enables sanding operations, but also effectively cleans the work area. The gap between the brushes can collect the debris generated by sanding, preventing it from accumulating inside the sanding machine and affecting the sanding effect or damaging other components of the sanding machine. This cleaning function helps to maintain the good working condition of the sanding machine, reduce maintenance costs, and improve production efficiency.

The sanding machine brush roller has multiple specifications to choose from, with a wide range of sizes, such as inner diameter x outer diameter x length (ф 8- ф 150) x (ф 25- ф 800) x (L10-L5000), and can also be customized according to customers' special needs. This means that whether your sanding machine is a large industrial equipment or a small processing tool, you can find a matching brush roller. At the same time, different sanding processes and processed materials can also achieve the best sanding effect by selecting appropriate brush rollers.

During the sanding process, it is inevitable to produce some debris and dust. The special structure of the sanding machine brush roller not only enables sanding operations, but also effectively cleans the work area. The gap between the brushes can collect the debris generated by sanding, preventing it from accumulating inside the sanding machine and affecting the sanding effect or damaging other components of the sanding machine. This cleaning function helps to maintain the good working condition of the sanding machine, reduce maintenance costs, and improve production efficiency.

The sanding machine brush roller has multiple specifications to choose from, with a wide range of sizes, such as inner diameter x outer diameter x length (ф 8- ф 150) x (ф 25- ф 800) x (L10-L5000), and can also be customized according to customers' special needs. This means that whether your sanding machine is a large industrial equipment or a small processing tool, you can find a matching brush roller. At the same time, different sanding processes and processed materials can also achieve the best sanding effect by selecting appropriate brush rollers.

Supplier's popular products

Contact Supplier

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.