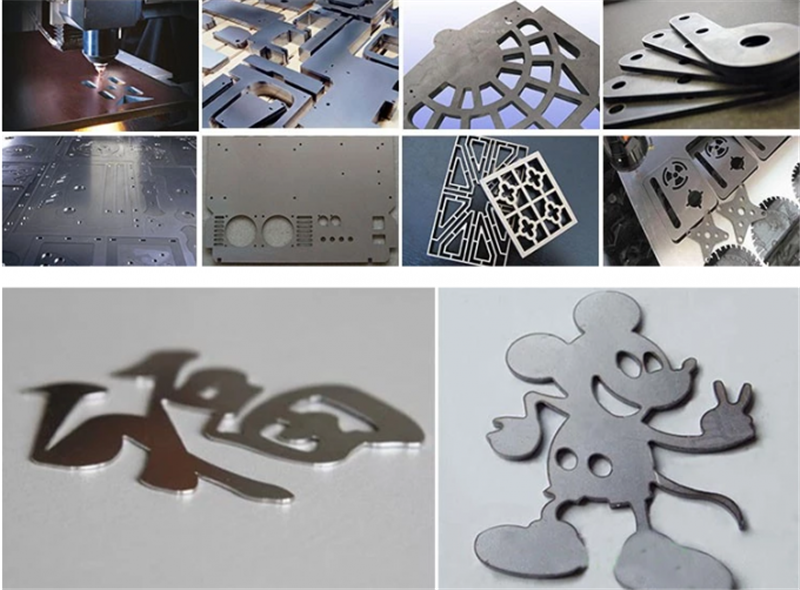

Sheet Metal Laser Cutter and Round Tube Pipe CNC Precision Fiber Laser Cutting Machine

Configuration and Technical Data

◆ Adopt industrial heavy duty steel structure,plate steel joint welding with square pipe steel,under heat treatment,will not deform after long time using.

◆ Adopt NC pentahedron machining,milling,boring,tapping and other machining processes to ensure high processing accuracy.

◆ Configure with Japan THK linear rail for all axis,to ensure durable and high precision for long time processing.

◆ X,Y axis configure with high accuracy grinding type gear rack,Japan Shimpo reducer,high speed and precision can be ensured.Z axis is transmitted by high accuracy rolling ball screw.

◆ Adopt France Schneider AC servo system,larger power,stronger torque force,working speed is more stable and faster.

◆ Adopt Japan SMC intelligent gas group,dual gas control,automatic adjustment for gas type and gas software.

◆ Adopt professional WSX,Raytools laser cutting head,imported optical lens,focus spot smaller,cutting lines more precise,higher efficiency and better processing quality can be ensured.

◆ Configure with non-contact auto follow function,ensure the best focal length and cutting effect.

◆ Fiber laser transmitting,flexible processing,realized high accuracy cutting on every point.

◆ Professional laser cutting CNC controlling system,connected with computer,simple operation.

◆ Configure with professional industrial chiller with double temperature control molds,high cooling efficiency and high transferring ratio of laser.

◆ Compatible with multiple software,can design ant graphic and letters as you like,operating simple,flexible and easy.

◆ Wide application:can be widely used in processing any stainless,carbon steel,alloy steel,silicon steel,spring steel,pickling steel plate,galvanized sheet,etc.

Keyi Laser is a world famous manufacturer of laser equipments focusing on the development and production of various types of laser machinery and CNC equipments. We strive to support you with acquiring the best laser marking machine, laser engraving machieor cutting machine for your unique application. Whether it's laser engraving, cutting, or marking we are here to help you advance your dreams. We strictly maintain quality assurance standards with our overseas suppliers. This allows us to offer a good compromise between quality and affordability.

2012 - Established in Wuhan , started to produce kinds of laser machienry such as laser marking machiners, laser cutting machiens, laser engraving machines .

2013 - adding three production lines due to the expand of the markets , Our products are wideley sold in domestic market and OEM for some trade company .

2014 - Start to export European market , such as Italy , Germany , Finland , Sweden .

2015 - Start to sold all over the world , emply more and more engineeers to offer overseas service .

2016 - rebuild a research and development department about cleaning machines

2017 - Keyilaser moved to new location due to scale expansion

2018 - Going to the world participate in the exhibition

1.Q:Are you a factory or trading company?

A:We are factory. located in 1ST FLOOR,BLOCK D,NO.7 BUILDING, CHANGZUI OPTOELECTRONIC INDUSTRIAL PARK, GAOXIN 6TH ROAD, ECONOMIC DEVELOPMENT ZONE JIANGXIA DISTRICT, WUHAN, HUBEI PROVINCE,CHINA..

2.Q:The material is harmful to the environment or not?

A:It is non-toxic and Eco-friendly.

3.Q:How can I get some samples?

A:(1)We can provide some small samples in stock, but you need to pay the freight.

(2)You need to pay the sample fee and freight for some samples.

4.Q: What is your shipping way?

A:We will help you to choose the best shipping way according to your detail requirements.

By sea, by air or by express, etc.

5.Q: What is the normal lead time?

A:(1)For stock products, about 7 days after we receive your payment.

(2)OEM/ODM product delivery date requires negotiation.

6.Q:Can I visit your factory?

A:Of couse, customers are welcome to visit our factory.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.