Rotary Automatic Packing Machine for premade bags

Function and Characteristics——Model of DC8-300 Rotary packing machine

1.Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

2.Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production.

3. Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

4. Safty device: Machine stop at abnormal air pressure, heater disconnection alarm.

5. Horizontal conveyer style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

6. The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clips, easily operate, and save time.

7.It matchs with the glass safty door. The machine will stop working when you open the door. So that it could protect the safty of operators. At the same time, it could prevent dust.

8. Use the plastic bearing, don’t need put on oil, less pollution.

9. Use no oil vacuum pump, avoid polluting the environment in the production.

10.The opening zipper framework is special in the feature of zipper bag,it can avoid distortion or destroy when opne the zipper.

11.The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification.

12.Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food.

13.With different metering device changed to pack granular,liquid,paste,powder and so on.

14.The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.

Function and Characteristics—— Model of M-10 10-head weigher

1.It can apply in:Dry & Processed Foods, Fresh Foods. Fox example: Sank Foods, Seeds(Pulses),Coffee(granules/beans), Tea, Sugar, Grated Cheese, Bakery Products, Candies & Confectionery, Rice, Nuts & Dried Fruits, Spices, small Pasta pieces, Pet Food(pellets) etc.

1.It can apply in:Dry & Processed Foods, Fresh Foods. Fox example: Sank Foods, Seeds(Pulses),Coffee(granules/beans), Tea, Sugar, Grated Cheese, Bakery Products, Candies & Confectionery, Rice, Nuts & Dried Fruits, Spices, small Pasta pieces, Pet Food(pellets) etc.

2. Use the digital sensors to enhance speed, precision and anti-jamming capatiblity.

3.Optional language of operation. English ,Japanese,Chines,Italian ,German,Spanish,Russian etc.

4.Frame with IP65 protection.

5.Statistical Data-Inspect on screen and via optional printer output.

Function and Characteristics—— Model of DT5 Bucket elevator(Include Feeder)

This kind of elevator is used mainly to convey the solid food ,such as rice, chip potato ,candy ,etc.it composes the automatic quantitative packing system combined with the weigher and packing machine, which is applying widely. Be made of 304 stainless steel and plastic (PP) which is hygienicand healthy .the elevator is controlled automatically.

Function and Characteristics—— Working platform(Carbon steel or 304 stainless steel)

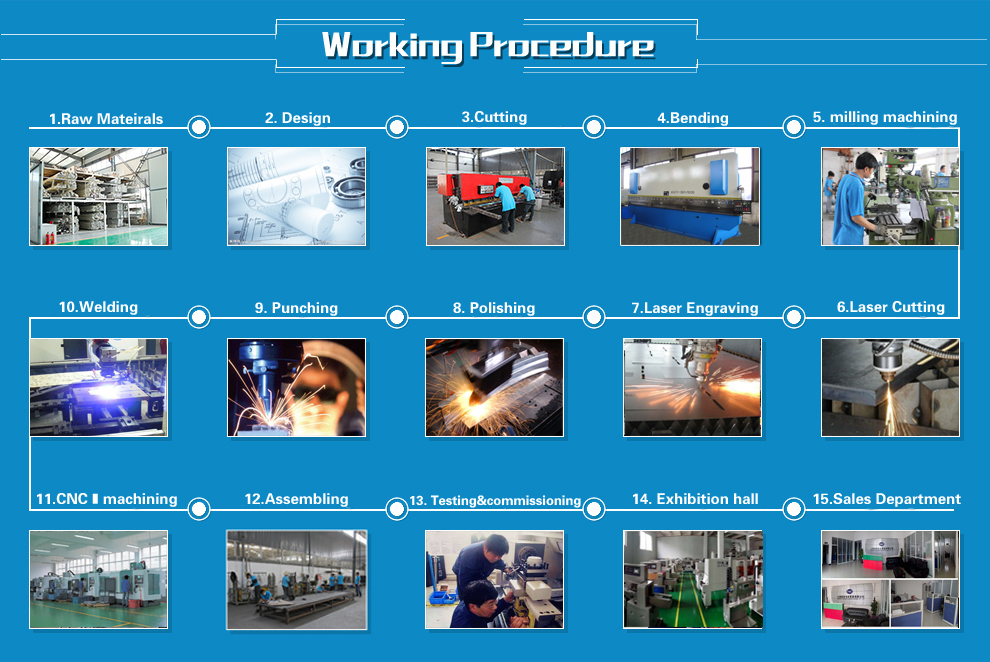

Working process

15 years manufacturing experence,your best choice.

Packing:

Machine packing inside is plastic films and outside is fumigation wooden case.Our wooden case is very strong,it can bear long time shipping on the sea.And machine with preservative film,it can stop the salt sea water enter into the machine and make the machine corrosion.

Shipping:

Upon receipt of payment , delivery date will be in 25-30days

By Air, by Sea or by Express (UPS,DHL etc.)

Shipment cost will depend on the destination, shipment way,size and the weight of the goods.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.