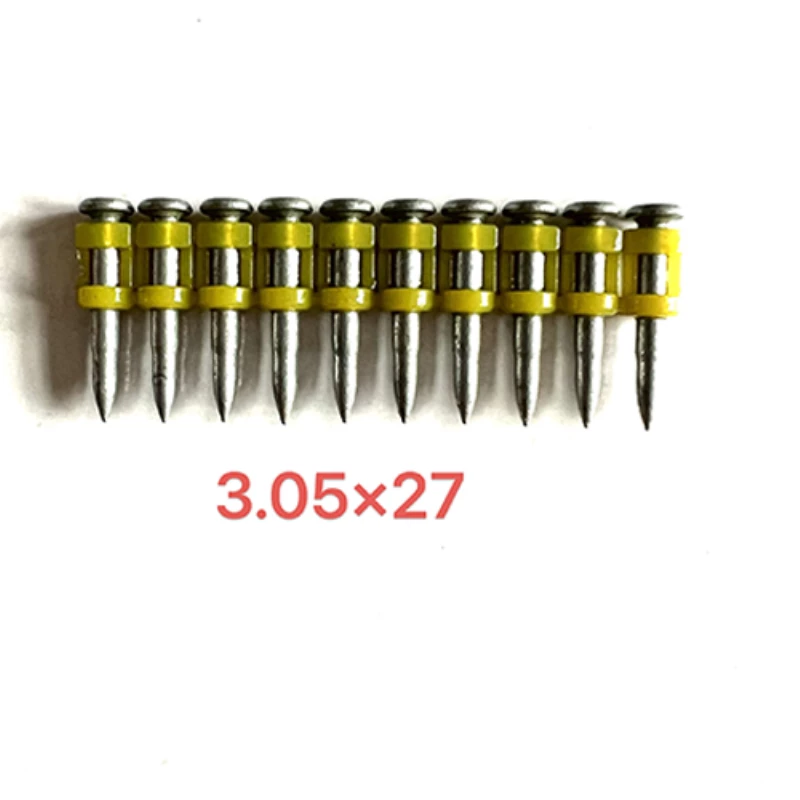

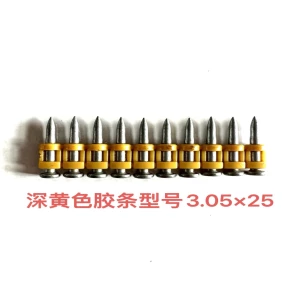

Reinforced nails for concrete metal Toua CN MG Bullet Point - 27 mm

- Length of nails

- 27 mm

- Gross weight

- 19 kg

- Length

- 27 mm

- Section

- 3.05 mm

- Rouble

- 1650

Other recommendations for your business

Bullet Point forged nails, like Toua heavy-duty nails, have a smaller body shape for better integration into high-density materials, and improved plating prevents corrosion, making them more suitable for outdoor installations and wet, corrosive environments such as coastal areas.

These nails have a variable body thickness - the body diameter of the nail is 3.05 mm, which is then reduced to a diameter of 2.7 mm by shrinking the nail.

The reduced nail body provides a "softer" entry point to the material, which improves the zeroing quality of difficult surfaces. The 3.05 mm diameter nail body in turn reduces the effect of bending loads when the nail is driven into a hard material.

Contact Supplier

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.