Real stone paint colorful paint cover smooth surface three in one automatic spraying machine

- Turbine worm gear reduction motor

- 0.75KW

- servo motor

- 3KW

- Servo drive

- ASD series

- PLC

- DVP series

- touch screen

- 7 inches

- Variable frequency speed governor

- 0.75KW

- linear guide rail

- QHW

- Upper silver rail slider

- HGW

- Axial flow fan

- 0.75KW

- Planetary gearbox

- PLE series

- Synchronous belt

- STD14M

- Synchronous wheel

- STD14M

- Multi wing centrifugal fan

- 7.5KW

- Genuine Stone Paint Gunrick Spray Gun

- one thousand and five hundred

- Screw pump (real stone paint)

- 5.5KW

- Glossy Iwata Spray Gun

- Caliber 1.5

- Diaphragm pump (glossy cover)

- A-20

- Colorful Lacquer Iwata Spray Gun

- Caliber 3.0

- Pressure tank (colorful paint)

- 80L

- Maximum workpiece length (mm)

- 3000

- Minimum workpiece length (mm)

- 300

- Maximum workpiece width (mm)

- 1300

- Minimum workpiece width (mm)

- 500

- Maximum workpiece thickness (mm)

- 8

- Minimum workpiece thickness (mm)

- 5

- Paint category

- Water soluble paint

- working pressure

- 0.6-0.8MPa

- Air usage

- 2Cubes per minute

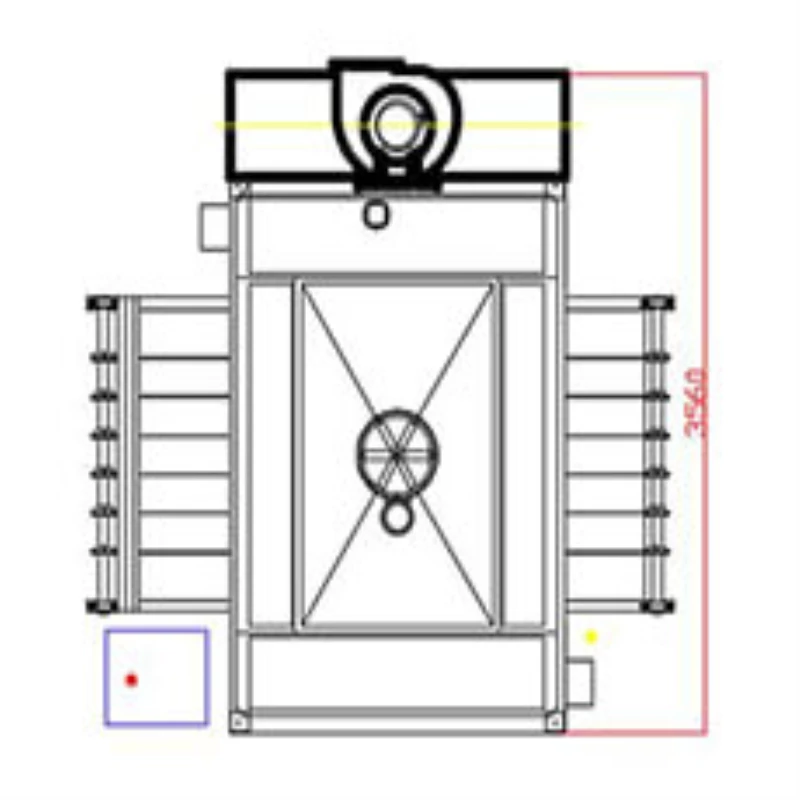

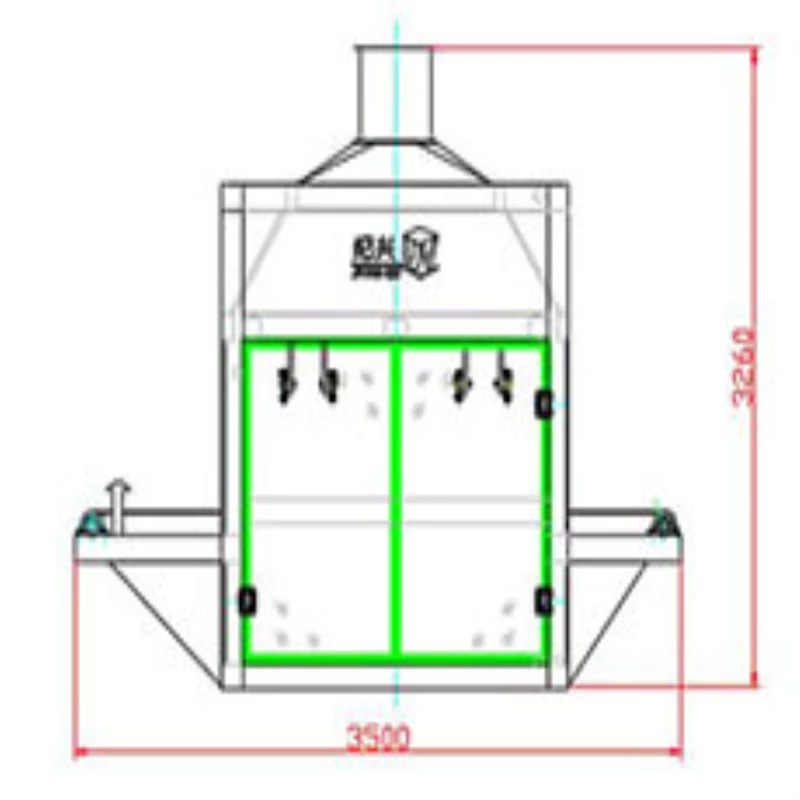

- Dimensions (mm)

- 3500X3560X3260

The Real stone paint, colorful paint, and cover smooth surface three - in - one automatic spraying machine by Jixingyuan is a highly efficient and versatile piece of equipment. It combines the functions of spraying real stone paint, colorful paint, and cover smooth surface coatings, designed to meet various painting needs in different industries.

The conveying device of this spraying machine is a key feature. It uses rubber - coated steel wire ropes, which are highly corrosion - resistant. This not only ensures a long - lasting service life but also prevents secondary pollution on the back of the plates during the spraying process. The conveying speed can be adjusted via frequency conversion, allowing for easy adaptation to different painting requirements. Inside the machine body, stainless - steel recovery troughs are installed on both sides, enabling the recycling and reuse of paint, which is both cost - effective and environmentally friendly. The automatic oil - adding lubrication system and double - linear self - cooling guide rails ensure stable movement of the gun wall, eliminating the need for manual oil injection.

The spraying device is equally impressive. The feeding system is equipped with a modified screw pump, which provides a stable flow of paint. This results in a more stable spraying operation and a fuller paint film. The low - entry feeding method simplifies the operation process and reduces labor requirements. The machine is equipped with high - quality spray guns, including Graco real - stone paint - specific spray guns from the United States, Iwata colorful paint - specific spray guns and Iwata cover - smooth - surface spray guns from Japan. These spray guns can be adjusted according to specific needs, allowing for excellent spraying effects on different - shaped materials. The spraying drive device is precisely driven by a Delta servo motor from Taiwan. With a linear speed of 2.5 meters, it offers accurate, fast, stable, and reliable reciprocating spraying motion, which is among the fastest in the domestic market.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.