specifications

|

TRLG insert specifications |

|||||||

|

number |

specification |

tip OD mm |

insert codes |

pad code |

insert screw |

pad screw |

wrench |

|

1 |

TRLG11.52-40 |

Ф11 |

LOGT060204R-IC908 |

GP04-055 |

M2.5×4.5 |

M2x3.7 |

T6/T8 |

|

2 |

TRLG12.02-40 |

Ф11.5 |

LOGT060204R-IC908 |

GP04-055 |

M2.5×4.5 |

M2x3.7 |

T6/T8 |

|

3 |

TRLG12.52-40 |

Ф12 |

LOGT060204R-IC908 |

GP04-055 |

M2.5×5 |

M2x3.7 |

T6/T8 |

|

4 |

TRLG13.02-40 |

Ф12.5 |

LOGT060204R-IC908 |

GP04-055 |

M2.5×5 |

M2x3.7 |

T6/T8 |

|

5 |

TRLG13.52-40 |

Ф13 |

LOGT060204R-IC908 |

GP04-055 |

M2.5×5 |

M2x3.7 |

T6/T8 |

|

6 |

TRLG14.02-45 |

Ф13.5 |

TOGT070304R-DT |

GP05-060 |

M2.5×5 |

M2.2×4.5 |

T7/T8 |

|

7 |

TRLG14.52-45 |

Ф14 |

TOGT070304R-DT |

GP05-060 |

M2.5×5 |

M2.2×4.5 |

T7/T8 |

|

8 |

TRLG15.02-45 |

Ф14.5 |

TOGT070304R-DT |

GP05-060 |

M2.5×6 |

M2.2×4.5 |

T7/T8 |

|

9 |

TRLG15.52-45 |

Ф15 |

TOGT070304R-DT |

GP05-060 |

M2.5×6 |

M2.2×4.5 |

T7/T8 |

|

10 |

TRLG16.02-50 |

Ф15.5 |

TOGT080305R-DT |

GP05-075 |

M2.5×6 |

M2.2×4.5 |

T7/T8 |

|

11 |

TRLG16.52-50 |

Ф16 |

TOGT080305R-DT |

GP05-075 |

M2.5×6 |

M2.2×4.5 |

T7/T8 |

|

12 |

TRLG17.02-50 |

Ф16.5 |

TOGT080305R-DT |

GP05-075 |

M2.5×6 |

M2.2×4.5 |

T7/T8 |

|

13 |

TRLG17.52-50 |

Ф17 |

TOGT080305R-DT |

GP05-075 |

M2.5×6 |

M2.2×4.5 |

T7/T8 |

|

14 |

TRLG18.02-55 |

Ф17.5 |

TOGT090305R-DT |

GP06-085 |

M2.5×6 |

M2.5×5 |

T8 |

|

15 |

TRLG18.52-55 |

Ф18 |

TOGT090305R-DT |

GP06-085 |

M2.5×6 |

M2.5×5 |

T8 |

|

16 |

TRLG19.02-55 |

Ф18.5 |

TOGT090305R-DT |

GP06-085 |

M2.5×6 |

M2.5×6 |

T8 |

|

17 |

TRLG19.52-55 |

Ф19 |

TOGT090305R-DT |

GP06-085 |

M2.5×6 |

M2.5×6 |

T8 |

|

18 |

TRLG20.02-60 |

Ф19.3 |

TOGT100305R-DT |

GP06-085 |

M3x7 |

M2.5×6 |

T8/T10 |

|

19 |

TRLG20.52-60 |

Ф19.8 |

TOGT100305R-DT |

GP06-085 |

M3x7 |

M2.5×6 |

T8/T10 |

|

20 |

TRLG21.02-60 |

Ф20.3 |

TOGT100305R-DT |

GP06-100 |

M3x7 |

M2.5×6 |

T8/T10 |

|

21 |

TRLG21.52-60 |

Ф20.8 |

TOGT100305R-DT |

GP06-100 |

M3x7 |

M2.5×6 |

T8/T10 |

|

22 |

TRLG22.02-65 |

Ф21.3 |

TOGT110405R-DT |

GP06-100 |

M3.5×9 |

M2.5×6 |

T8/T15 |

|

23 |

TRLG22.52-65 |

Ф21.8 |

TOGT110405R-DT |

GP06-100 |

M3.5×9 |

M2.5×6 |

T8/T15 |

|

24 |

TRLG23.02-65 |

Ф22.3 |

TOGT110405R-DT |

GP06-100 |

M3.5×9 |

M2.5×6 |

T8/T15 |

|

25 |

TRLG23.52-65 |

Ф22.8 |

TOGT110405R-DT |

GP06-100 |

M3.5×9 |

M2.5×6 |

T8/T15 |

|

26 |

TRLG24.02-70 |

Ф23.3 |

TOGT110405R-DT |

GP06-100 |

M3.5×9 |

M2.5×6 |

T8/T15 |

|

27 |

TRLG24.52-70 |

Ф23.8 |

TOGT110405R-DT |

GP06-100 |

M3.5×9 |

M2.5×6 |

T8/T15 |

|

28 |

TRLG25.02-70 |

Ф24.2 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

29 |

TRLG25.52-70 |

Ф24.7 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

30 |

TRLG26.02-75 |

Ф25.2 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

31 |

TRLG26.52-75 |

Ф25.7 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

32 |

TRLG27.02-75 |

Ф26.1 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

33 |

TRLG27.52-75 |

Ф26.6 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

34 |

TRLG28.02-80 |

Ф27 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

35 |

TRLG28.52-80 |

Ф27.5 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

36 |

TRLG29.02-80 |

Ф28 |

TOGT120405R-DT |

GP06-120 |

M4x10 |

M2.5×6 |

T8/T15 |

|

37 |

TRLG29.52-80 |

Ф28.5 |

TOGT130408R-DT |

GP06-120 |

M5x11 |

M2.5×6 |

T8/T20 |

|

38 |

TRLG30.02-85 |

Ф29 |

TOGT130408R-DT |

GP07 |

M5x11 |

M3x6.5 |

T8/T20 |

|

39 |

TRLG30.52-85 |

Ф29.5 |

TOGT130408R-DT |

GP07 |

M5x11 |

M3x6.5 |

T8/T20 |

|

40 |

TRLG31.02-85 |

Ф30 |

TOGT130408R-DT |

GP07 |

M5x11 |

M3x6.5 |

T8/T20 |

|

41 |

TRLG31.52-85 |

Ф30.5 |

TOGT130408R-DT |

GP07 |

M5x11 |

M3x6.5 |

T8/T20 |

|

42 |

TRLG32.02-85 |

Ф31 |

TOGT130408R-DT |

GP07 |

M5x11 |

M3x6.5 |

T8/T20 |

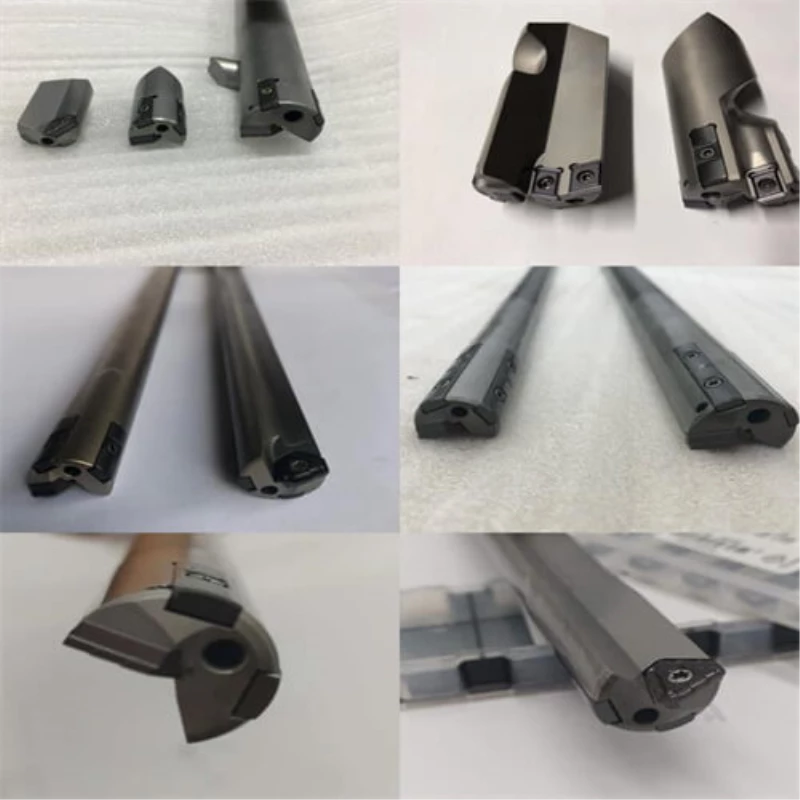

Carbide Indexable Gun Drills

Advantages

Versatility for use on lathe, machining centers and deep hole machines.

High effieciency by specifically developed cutting edge geometry for diea chip formation

Shortens downtime resulting from quick exchange of worn parts

Easy to use, no sharpening, no length adjustment, easy inventory of wear parts.

Lengthens tool life due to full coating, edge treatment and indexable designs

Quick availability due to stocked wear parts and most common boy sizes.

Triangle inserts have 3 cutting edges. Positive rake chip breakers and chip splitting geometries allow the use of feed rates 3 to 4 times greater than that of traditional gun drills. They are manufaturered from micrograin carbide and available in several PVD wear resistant coatings.

Applications

Medical instruments, automotive fuel systems, the glass industry, and many other applications can benefit by gundrilling very small holes with solid carbide flute drills. The strength afforded by the absence of a braze joint at the tip with tubular construction gun drills provides better penetration rates and tool life. However, gun drills of such small diameters require that the specific operating parameters are followed to ensure success. We are pleased to offer expert application engineering to make this happen.

Dezhou Kabaide Cutting Tool Co.,Ltd is a manufacturer of gun drills, located in Dezhou,Shandong which is a base city for deep hole drilling. Our brand is “KBD". We can produce many sizes of gun drills as well as non standard gun drills according to clients' special requirements.

We focus on gun drill production business. We have special deep hole drilling tool machines.

Our company invites famous cutting tool professors in this industry to instruct the research and development.With many years development,we have our own technique process, and registered our own brand.Nowadays,our products are sold well in domestic market and overseas,and are highly praised by our customers.

As a good private owned company, we have innovative,capable and flexible structure,and complete and scientific quality control system.Our gun drills are high hardness,good rigidity,high accuracy,long lasting,and good cost performance.

Continuous improvement of the process, solid progress to produce the gun drills, creating a national brand,and to pursue the excellence is our eternal goal.

Q: Do you sell parts?

A: If you ordered an item from us and need a replacement part outside of warranty coverage, we are happy to help you place a replacement parts order!

Q: Do you only sell genuine products?

A: Yes! We are proud to only sell only the best quality authentic products. Counterfeits are not allowed on our website.

Q: What is the warranty coverage for the items I’m interested in?

A: Most of our products have warranties on manufacturing defects. Some products also offer a complete warranty from 1-5 years from the date of purchase. These warranties vary from

item to item! Which may be mentioned on the product listing, for any further queries, contact us regarding this and we will be happy to help.

Q: How do I know if your product listings are accurate?

A: We have a lot of item data constantly being updated! Sometimes this may lead to issues like inaccurate product information, incorrect pricing or outdated product availability. We apologize for those issues.

Q: I checked out the shipping ETA on the product page, but I need this item sooner! Can you ship it any faster?

A: If you need your product faster than what is estimated, we may be able to offer overnight or two-day delivery at an additional charge. You can raise such a request and our team can update the shipping options on the phone and can choose the suitable option by paying the corresponding charges.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.