Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

1. Application of Solar Powered LED Street Lighting

LED lighting offers high efficiency, long operating life and low voltage operation which ideal for solar

Solar street lights were initially used in remote locations and disaster prone areas

As LED efficacy and light output have improved, they are becoming mainstream.

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

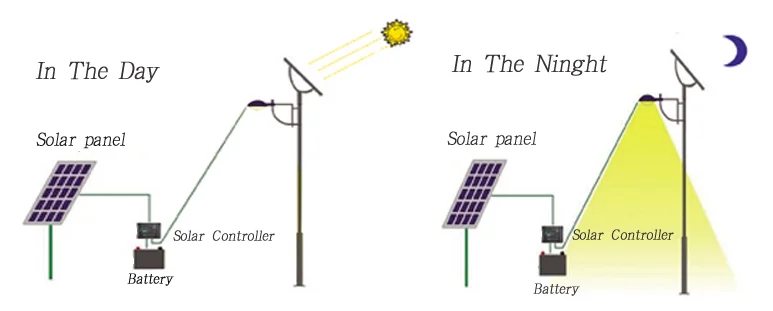

How solar street light works?

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Working principle of solar street lamp: under the control of intelligent controller, solar energy street lamp absorbs solar energy and converts it into electric energy after being illuminated by sun light in the daytime. Solar cell module charges battery pack in the daytime, and battery pack provides power to LED light source in the evening to realize lighting function. The DC controller can ensure that the battery is not damaged due to overcharge or overdischarge, and has the functions of light control, time control, temperature compensation, lightning protection, reverse polarity protection, etc

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

2.Advantages of Solar Powered LED Street Lighting

1. Solar street lights are independent of the utility grid. Hence, the operation costs are minimized.

2. Solar street lights require much less maintenance compared to conventional street lights.

3. Since external wires are eliminated, risk of accidents are minimized.

4. Electricity produced from solar panels is non-pollutive.

5. Separate parts of a solar panel system can easily be transported.

6. Energy costs can be saved.

It is mainly suitable for lighting of urban roads, community squares, industrial parks, tourist attractions, park green belts and other places.

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

3. Components of Solar Powered LED Street Lighting

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

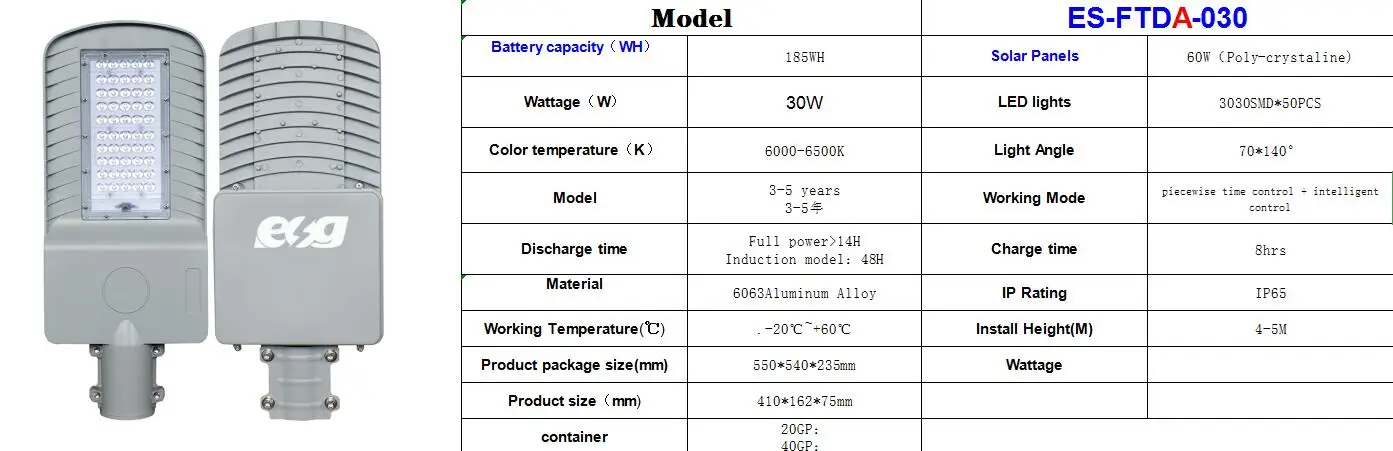

4. Parameter of Solar Powered LED Street Lighting

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

| SOLAR PANEL (different types optional) | |

| MONO SOLAR PANEL, efficiency up to 18.5% | 1. Grade A high efficiency solar panel 2. high strenth aluminum frame and fine surface treatment 3. Optical tempered glass to enhance the charging performance |

| MONO SOLAR PANEL, efficiency up to 18.5% | |

| Battery (different types optional) | |

| LEAD ACID BATTERY | 1. Deep cycle 800 times at 50% discharging 2. 2% low self-discharge per month 3. 5-8 years life span |

| LITHIUM BATTERY | 1. 2000 cycle times at 80% discharge 2. deep discharging performance 3. Small and light |

| LED lamp | 1. >150lm/W CREE LED light source with life >50,000hrs 2. individual lamp body with high heat dissipation aluminum material for an advanced heat management 3. professional optical lenses for high surface lux level |

| Controller | 1. LED driver built-in with intellectual working functions 2. Dimming based on time phase and automatic dimming function 3. MPPT type available for higher efficiency 4. with remote control |

| Pole | 1. high thiness Q235 steel 2. hot-dip galvanization and powder coating for high anti-corrosion performance 3. high strength foundation cage included 4. high strength full frame solar panel mounting bracket with wind resistant design |

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

ry sing separaed Ip65 DC split outdoor solar LED street light with lithium batter

5.More LED lights for Solar Powered LED Street Lighting to choose

We can provide a variety of lamps, nearly 200 styles, power support 30W ~ 200W. Here below are just some lamps for your reference. For more details, more choices, just contact with us without any hesitation.

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

6.Different component designs for different Solar Powered LED Street Lighting

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

| Item | Product Name | System type | COMPONENTS | Working time | |||

| Solar Panel | Controller | Battery | LED light | Hours | |||

| 1 | 30W Solar Street Lights | off grid | 100W * 1 | 12V 10A | 12V 80AH * 1 | 30 W | 12 |

| 2 | 50W Solar Street Lights | off grid | 150W * 1 | 12V 10A | 12V 100AH * 1 | 50 W | 12 |

| 3 | 60W Solar Street Lights | off grid | 180W * 1 | 12V 10A | 12V 120AH * 1 | 60 W | 12 |

| 4 | 80W Solar Street Lights | off grid | 130W * 2 | 24V 10A | 12V 80AH * 2 | 80 W | 12 |

| 5 | 100W Solar Street Lights | off grid | 150W * 2 | 24V 10A | 12V 100AH * 2 | 100 W | 12 |

| 6 | 120W Solar Street Lights | off grid | 200W * 2 | 24V 20A | 12V 150AH * 2 | 120 W | 12 |

Please contact with us for detailed quotations!!!

7. LED Street Lighting Certification

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

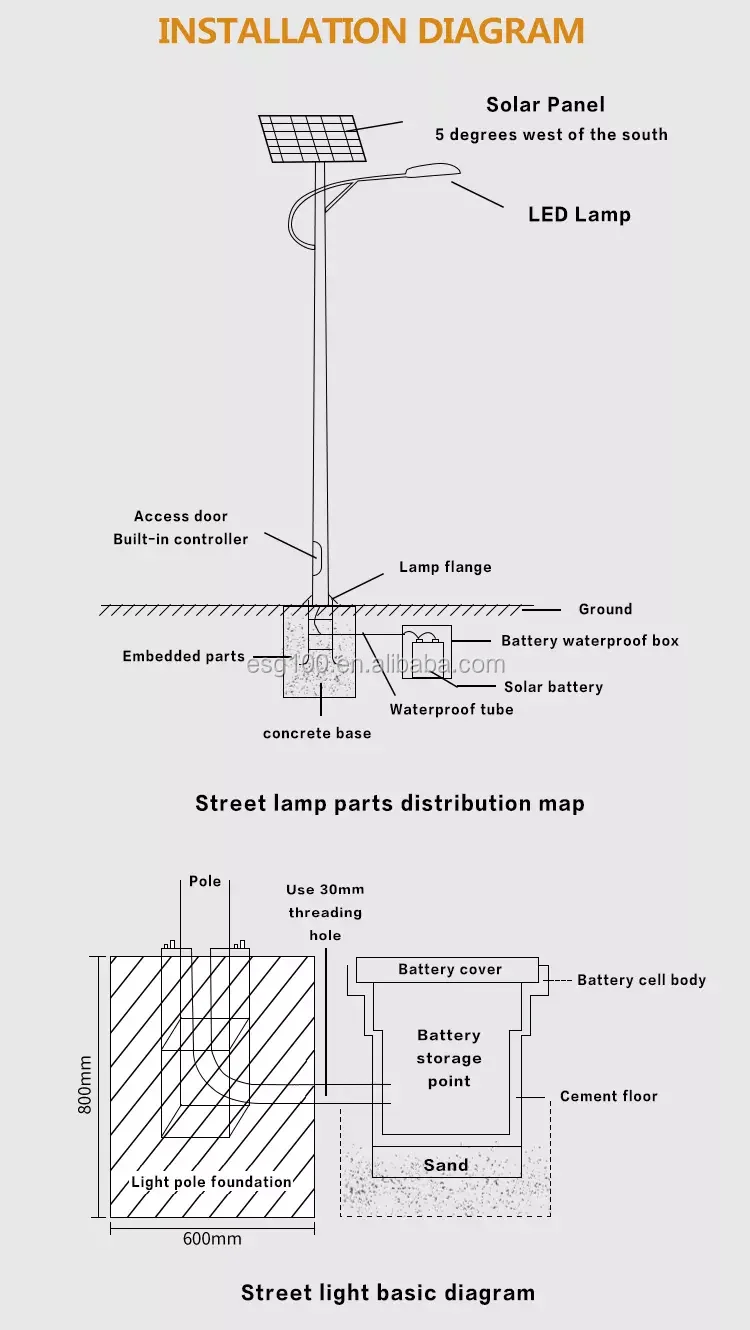

8.Installation Diagram for Solar Powered LED Street Lighting

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

9.Solar Powered LED Street Lighting

Foundation pouring

1. Determine the position of the vertical lamp; survey the geological conditions. If the surface is 1 m 2 soft soil, the excavation depth should be deepened; at the same time, make sure that there are no other facilities (such as cables, pipes, etc.) below the excavation position, and there is no long-term sunshade object on the top of the street lamp, or change the position properly.

2. Reserve (excavate) 1 m 3 pits that meet the standard at the position where the lamps are erected; place the embedded parts. The embedded parts are placed in the middle of the square pit, one end of the PVC conduit is placed in the middle of the embedded parts, and the other end is placed in the storage place of the battery (as shown in the above figure). Pay attention to keep the embedded parts, foundation and original ground on the same horizontal plane (or the top of screw and original ground on the same horizontal plane, depending on the needs of the site), one side should be parallel to the road; in this way, the lamp post can be upright without deflection after being erected. Then, C20 concrete shall be poured and fixed. During the pouring process, the vibrating rod shall not be stopped to vibrate to ensure the overall compactness and firmness.

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

3. After the construction, clean up the residual sludge on the positioning plate in time, and clean the impurities on the bolts with waste oil.

4. In the process of concrete solidification, the concrete shall be watered regularly for maintenance; the chandelier can be installed only after the concrete is completely solidified (generally more than 72 hours)

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Installation of solar panel components

1. Before connecting the positive and negative poles of the solar panel to the controller, measures shall be taken to avoid short circuit;

2. The connection between the solar panel and the bracket shall be firm and reliable;

3. The output line of the component shall not be exposed, and shall be firmly tied with a cable tie;

4. The orientation of the battery assembly shall be toward the south, subject to the direction of the compass

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Battery installation

1. When the battery is placed in the control box, it shall be handled with care to prevent damaging the control box;

2. The connecting wire between the batteries must be pressed on the battery terminal with bolts and copper gasket to enhance the conductivity;

3. After the output line is connected to the battery, it is forbidden to short circuit under any circumstances to avoid damage to the battery;

4. When the output line of the battery is connected with the controller in the pole, it must pass through the PVC conduit;

5. After the completion of the above, check the wiring at the controller end to prevent short circuit. Close the door of the control box after normal operation

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Lamp installation

1. Fix the components of each part: fix the sun plate on the sun plate bracket, fix the lamp cap on the cantilever, then fix the bracket and the cantilever to the main pole, and lead the connecting wire to the control box (battery box).

2. Before lifting the lamp pole, check whether the fasteners at all parts are firm, whether the lamp head is installed correctly, and whether the light source works normally. Then, whether the simple debugging system works normally or not; release the connecting line of the solar panel on the controller, and the light source works.

3. Pay attention to safety precautions when lifting the main light pole; the screws shall be absolutely tightened. If the sunrise angle of the component is deviated, it is necessary to adjust the sunrise direction of the upper end to the south.

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

4. Put the battery into the battery box, and connect the connecting wire to the controller according to the technical requirements; connect the battery first, then the load, and then the solar panel; during the wiring operation, it must be noted that the wiring of each circuit and the wiring terminal marked on the controller cannot be connected wrongly, the positive and negative polarity cannot be collided, or connected reversely; otherwise, the controller will be damaged.

5. Debug whether the system works normally; release the connecting line of the solar panel on the controller, and the light will be on; connect the connecting line of the solar panel, and the light will be off; at the same time, carefully observe the changes of the indicator lights on the controller; only when everything is normal, can the control box be sealed.

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

10.Installation Suggestion for Solar Powered LED Street Lighting

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

| Street lamp height from the ground | power | Effective illuminated Area | Pole Spacing |

| 3~4m | 20~30w | 20 m² | 10~15m |

| 5~6m | 50~60w | 45~55 m² | 15~20m |

| 7~8m | 80~100w | 60~80 m² | 18~24m |

| 9~10m | 120~150w | 90~100 m² | 24~30m |

| 11~12m | 180~200w | 120 m² | 30~36m |

11.Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light process

12. Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light Packing

13.Solar Powered LED Street Lighting and other kind More related products

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

solar wind hybrid street lights all-in-one solar street lights other split solar street lights

Wind turbines and wind systems Solar Systems Solar Panels

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

14.Company Profile

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

15.Contact information

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

16.FAQ

Q 1: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q 2: What is the lead time?

A: Samples need 3-5 working days, mass products need 7-15 days.

Q3:How do you ensure the quality

A: We get three QC processes:1.For raw materials;2.During the half of production; 3.Final QC test one by one after aging 12 hours.

Outdoor Highway parking lot Ip65 DC 30w Aluminum Alloy split solar LED street light

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.