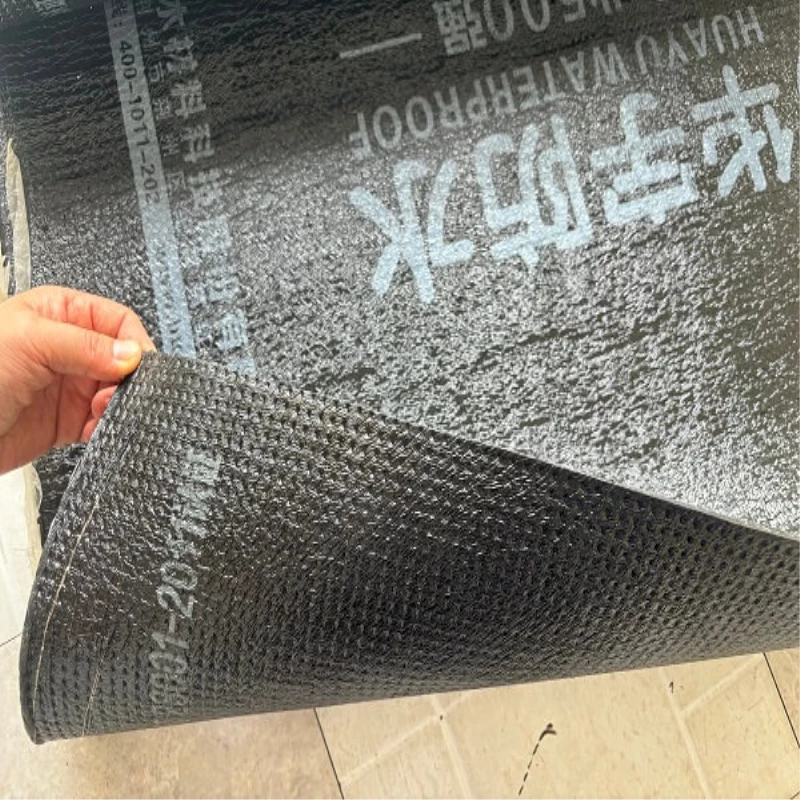

Modified bitumen composite copper tire root&puncture resistant waterproof membrane

- Packaging

- cylindrical shape and packaged with appropriate packing materials.

- Thickness(MM)

- 4.0

- Width(M)

- 1.0

- Length(M/Roll)

- 10.0

- Square Meter(㎡/Roll)

- 10.0

- Upper Surface isolation Material

- Polyethylene film (PE)

- Lower Surface isolation Material

- Polyethylene film (PE)

Product specification:

Packaging: Cylindrical shape and packaged with appropriate materials.

Width (m): 1.0

Thickness (mm): 4.0

Length (m): 10

Area (㎡/roll): 10

Upper surface isolation material: Polyethylene film (PE)

Lower surface isolation material: Polyethylene film (PE)

Product performance:

|

Performance |

Technical Indicators |

Typical values |

|

Soluble Matter Content (4mm) |

≥2900 g/m2 |

3179g/m2 |

|

Heat Resistance |

105℃No flow, no dripping |

Qualified |

|

Low-Temperature Flexibility |

-25℃ No Crack |

Qualified |

|

Tensile Strength |

≥800 N/50mm |

913 N/50mm |

|

oil penetration |

≤2 piece |

1 piece |

|

Lower Surface thickness of bitumen Coating Membrane |

≥1.0 mm |

1.3 mm |

Product Features

1、 The composite copper mat serves as a reinforcement layer, providing resistance to punctures, abrasion, and tearing, enhancing the material's strength and effectively resisting damage and destruction from both the upper and lower surfaces.

2、The copper ions within the composite copper mat help to inhibit the growth of plant root apical meristems, controlling the roots from growing towards the waterproof layer. It offers excellent root penetration resistance without affecting the normal growth of plants while maintaining long-term waterproof functionality. It also has outstanding resistance to corrosion and mold.

3、The product does not flow at high temperatures and does not crack at low temperatures, offering a wide range of usable temperature conditions (high temperature: 105°C, low temperature: -25°C).

How to Use

Hot Melt Construction:

- Construction Process -Subgrade treatment → Additional layer construction → Hot melt large area construction (rolling out the membrane) → Air expulsion and compaction → Water test → Protective layer construction

Construction Key Points:

1、 Subgrade treatment: Clean the surface first; the subgrade should be solid, flat, and clean; apply a primer evenly, ensuring full coverage without missing any spots; wait until the surface is dry before laying the membrane.

2、 Additional layer construction: Additional layers should be applied to areas such as corners, pipe roots, gutters, and expansion joints, by laying pre-cut pieces of membrane onto the subgrade.

3、 Large area construction: Use non-curing coatings for hot adhesive waterproof membrane composite construction, ensuring the coating thickness meets relevant specifications; while brushing the non-curing coating, roll out the waterproof membrane.

4、 Overlap treatment: The overlap width of the membrane should be 100mm; the overlap area should be sealed separately, using the hot melt method for construction, with the overlap of the upper and lower membranes considered adequate if bitumen is squeezed out.

5、 Water test: Conduct a water test according to the construction plan requirements.

6、 Protective layer construction: A protective layer should be set up on the outer surface of the waterproof layer according to relevant specifications or design requirements.

Hot adhesive Construction:

- Construction Process -Sub-grade treatment → Additional layer construction → Hot adhesive large area construction → Air expulsion and compaction → Water test → Protective layer construction

- Construction Key Points -

1、 Subgrade treatment: Clean the surface first; the sub-grade should be solid, flat, and clean.

2、 Additional layer construction: Additional layers should be applied to areas such as corners, pipe roots, gutters, and expansion joints, by pre-cutting the membrane to the appropriate size and shape.

3、 Large area construction: Use non-curing coatings for hot adhesive waterproof membrane composite construction, ensuring the coating thickness meets relevant specifications; while brushing the non-curing coating, roll out the waterproof membrane.

4、 Overlap treatment: The overlap width of the membrane should be 100mm; the overlap area should be sealed separately, using the hot melt method for construction, with the overlap of the upper and lower membranes considered adequate if bitumen is squeezed out.

5、Water test: Conduct a water test according to the construction plan requirements.

6、 Protective layer construction: A protective layer should be set up on the outer surface of the waterproof layer according to relevant specifications or design requirements.

Precautions:

1、 Prohibited from construction during rainy, snowy weather, or when winds exceed force 5.

2、 The construction environment temperature should not be below 0°C.

3、 The distance between the nozzle of the flame heater and the surface of the membrane should be moderate; heating within the width of the membrane should be even, with the membrane surface melted to a bright black color; avoid overheating the membrane.

4、 Ensure full safety protection facilities at the construction site, and place fire-fighting equipment as required.

Product Application:

It suitable for waterproofing projects on green roofs and top slabs of underground structures.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.