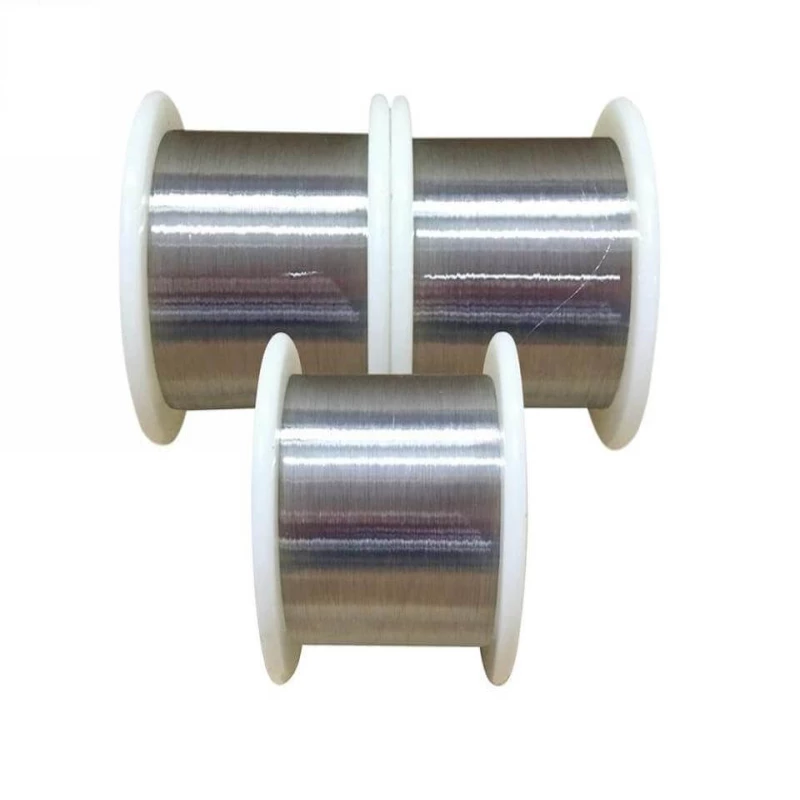

Medical Grade nitinol shape memory alloy wire,super elastic nitinol wire for sale

About Nitinol metal.

Highlight Features

Dia: 0.05-7 mm*10-10000 mmAF: 20~80 degree

Specification: ASTM F2063

Surface: Black, Polishing, Pickling

Application in Medical: (surgical, oral), Orthodontic wire, Guide wire, Guide pin.

Industry: Eyeglass Frames and Engineering Accessories, Springs, Pipe Joints and Fasteners, Super Elastic Anti-Loose,Components.

Nitinol wire Nitinol is a nickel-titanium alloy with superelasticity and shape memory properties. Shape memory refers to the

ability of Nitinol to undergo deformation at one temperature and then recover its original, under-formed shape upon heating above

its transformation temperature. Superelasticity occurs at a narrow temperature range just above its transformation temperature; in

this case, no heating is necessary to cause the under formed shape to recover, and the material exhibits enormous elasticity, some10-30 times that of ordinary metal.

| Product Name | Memory Nitinol wire |

| Standard | ASTM F2063 |

| Product Brand | OCEAN |

| Size | Dia(0.05-7) *L |

| Certification | ISO9001:2015 |

| MOQ | 5 kilograms |

| Surface | Polished picking rolled |

| Type | Straight , Spool ,Coil |

| Available Material | 55% Nickel and 45% Titanium. |

| Package | Plastic foam inside, wooden case outside as export standard |

| Lead time | 5-7 days after payment |

| Name | Grade | Transformation Temperature AF | Form | Standard |

| Shape Memory Nitinol Alloy | Ti-Ni-01 | 20 °C~ 40 °C | Wire, |

Customer specified or

Industry standard

|

| Ti-Ni-02 | 45 °C~ 90 °C | |||

| Superelastic Nitinol Alloy | TiNi-SS | -5 °C~ 5 °C | ||

| Low Temperature Superelastic Nitinol Alloy | TN3 | -5°C~ -15°C | ||

| TNC | -20°C~ -30°C | |||

| Medical Nitinol Alloy | TiNi-SS | 33 ± 3 °C | ASTM F2063 | |

| Narrow Hysteresis Nitinol Alloy | Ti-Ni-Cu | As-Ms ≤ 5 °C | Wire, bar | |

| Wide Hysteresis Nitinol Alloy | Ti-Ni-Fe | As-Ms ≤ 150 °C |

| Alloy |

Chemical

composition

|

Af

(Fully annealed)

|

Min. to failure [%] |

Max. Residual

elongation

after 6%

strain [%]

|

Main Applications | Specifications | |

|

Superelastic

Ni-Ti alloy

|

TiNi-SS | Ti-50.8at% | -5°C ± 5°C. | 10 | 0.1 | Eyeglass Frames, Cellular Phone Antennae, Bra Underwire | Q/XB1516.2 Q/XB1516.2 |

| TN3 TNC | TiNiVAl TiNiCr | -40°C ~50°C | 10 | 0.1 | |||

|

Body temperature

Ni-Ti alloy

|

TiNi-YY | Ti-50.7at%Ni | Functional Af=33 ± 3 | 15 | 0.1 | Implantable devices,Bone staples Vascular Stents | ASTM 2063 |

| Ti-Ni-01 | 55.6~55.8 wt%Ni | 20 - 40 | 15 | 0.1 | Guide wires, Stents Orthodontic Arches | Q/XB1516.1 | |

| High temperature Ni-Ti alloy | Ti-Ni-02 | 54.8~55.5wt%Ni | 45 - 95 | 10 | 0.1 | Implantable active devices, Surgical tools, Thermostats Coffeepots | Q/XB1516.1 |

| TiNiCu | TiNiCu | As-Ms ≤ 5 | 10 | 0.1 | |||

Nickel-titanium alloy is a shape memory alloy, which is a special alloy that can automatically restore its plastic deformation to its original shape at a certain temperature. The expansion rate exceeds 20%, and the fatigue life can reach the power of 1*10~7. Its damping performance is more than 10 times higher than that of ordinary springs, and its corrosion resistance is better than the current better medical stainless steel. It can meet various engineering needs. An excellent medical functional material. In addition to its unique shape memory function, memory alloys also have excellent properties such as wear resistance, corrosion resistance, high damping, and superelasticity.

Nitinol with special properties

1. Shape memory feature (shape memory) means that when a parent phase of a specific shape is cooled from a temperature higher than Af to a temperature lower than Mf to form martensite, it deforms and is heated to a temperature lower than Af. The material automatically restores its shape on parent and on reverse phase transition. In fact, the shape memory effect of Nitinol is a thermally induced phase transition process.

2. Superelasticity (superelasticity) The so-called superelasticity refers to the phenomenon that the specimen undergoes a strain far greater than its elastic limit under the action of an external force, and the strain energy automatically recovers when it is unloaded. That is, in the parent phase state, stress-induced martensitic transformation occurs due to the effect of external stress, so the alloy has mechanical behavior different from that of general materials. Its elastic limit is much larger than that of general materials, and it no longer conforms to the K law. Superelasticity is immune to the thermal effects of the shape memory effect. Superelasticity means that the stress does not increase with the increase of strain within a certain deformation range. Hyperelasticity can be divided into linear hyperelasticity and nonlinear hyperelasticity. The stress-strain relationship is close to linear on the original stress-strain curve. Nonlinear hyperelasticity refers to the result of stress-induced martensitic transformation and its reverse transformation during loading and unloading within a certain temperature range. So nonlinear hyperelasticity is also called phase transition pseudoelasticity. The phase change pseudoelasticity of nickel-titanium alloy can reach about 8%. The superelasticity of Nitinol varies with heat treatment conditions. Above 400°C, after the arch wire is heated, the superelasticity begins to decrease.

3. Sensitivity to oral temperature changes: The orthodontic force of stainless steel wire and CoCr alloy orthopedic wire is basically not affected by oral temperature. The corrective force of the superelastic nickel-titanium alloy orthopedic wire varies with the oral temperature. When the amount of deformation is constant. The correction force increases with temperature. First, it speeds up the movement of the teeth. As changes in the temperature of the mouth stimulate the cessation of blood flow caused by the orthodontic appliance, the repairing cells are adequately nourished as the tooth moves. maintain its vitality and normal function. Additionally, orthodontists cannot accurately control and measure orthodontic forces in the oral environment.

4. Corrosion resistance: Studies have shown that the corrosion resistance of nickel-titanium wire is similar to that of stainless steel wire.

5. Anti-toxicity: Nickel-titanium memory alloy has a special chemical composition, such as nickel-titanium, which contains about 50% nickel. Nickel has carcinogenic and cancer-promoting effects. Typically, the titanium oxide surface layer acts as a barrier, making the alloy biocompatible. TiXOy and TixNiOy on the surface can inhibit the release of nickel.

6. Mild orthodontic force: The orthopedic wires currently used in the market include austenitic stainless steel wire, cobalt-chromium-nickel alloy wire, nickel-chromium alloy wire, Australian alloy wire, gold alloy wire and titanium alloy wire. The load-displacement curves of such orthodontic wires in tension and three-point bending were studied. Nitinol had a lower unloading curve plateau with a higher plane, indicating that it provided the longest-lasting, softest correcting force.

7. Good shock absorption performance: the greater the vibration of chewing and molars at night, the greater the damage to the root and periodontal tissue. The test results show that the amplitude of the stainless steel wire is larger than that of the superelastic NiTi wire. The initial amplitude of the superelastic nickel-titanium archwire is only half that of the stainless steel wire. Oral health is important, and traditional arch wires, such as stainless steel wires, tend to increase root resorption.

The clinical application of nickel-titanium alloy wire:

1. It is used for early correction of the patient's dentition. Due to its superelasticity, shape memory properties, and low stress-strain curve, nickel-titanium alloy arch wires are often included in therapeutic systems and become the initial stage of clinical application. Thereby greatly reducing the discomfort of the patient. In the case of a variety of different correction technologies, the MBT technology recommends the use of 0.016-inch heat-activated nickel-titanium alloy arch wire (HANT wire), and the DEMON self-locking bracket technology recommends the use of copper-containing nickel-titanium produced by Omcro. Using O-PAK correction technology, the phase transition temperature of the 0.016-inch super-elastic nickel-titanium alloy arch wire is about 40 degrees, which is used for early alignment and straightness.

2. Nickel-titanium spring: Ni-titanium spring and extended spring are all springs for orthodontics. They are very resilient and can be used in orthodontic treatment to open gaps between teeth and pull teeth in different directions. When the nickel-titanium coil spring is pulled out about 1mm, it can generate about 50g force. Nickel-titanium coil spring is a highly elastic coil spring that can produce a soft, stable continuous force in a stretched state. The attenuation of this force is small, which can generate an ideal orthodontic force and meet the needs of clinical tooth movement. Meet physiological requirements. Nitinol wire tension spring has high elasticity and low deformation rate. The released correction force is 3.5-4 times that of stainless steel wire with the same diameter. When applying orthodontic treatment, patients not only have less pain, but also feel soft and durable, which can shorten the follow-up time, shorten the course of treatment, and improve the curative effect. This is a new type of mechanical equipment for orthodontic treatment.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.