Manufacturer steel braided corrugated flexible metal hose

Metal hoses are an indispensable part of modern technology with its high demands on piping systems for a wide variety of media and temperatures, like water, steam, hot oil and gas. High flexibility and highest pressure and temperature resistance characterize our product program and allow their use in many areas, notably in heating, plumbing systems, in the oil and gas industry, in the chemical industry, in machine and equipment construction.

Flexible metal hoses may be strengthened by double braiding in order to increase their resistance to pressure and environmental conditions. It is also possible to reinforce them by springs with different wire thicknesses or by strip wounds to lengthen their service life for more severe environmental conditions.

Reasons for the use of metal hoses rather than a solution with rigid tubes

• Stresses in the pipe system

Due to stresses in the pipe system may occur

- assembly inaccuracies

- thermal expansion

- vibrations

- pressure variations

To compensate for these unwanted stresses, a metal hose assembly provides the following advantages:

- no pipe ruptures due to fatigue

- no leaky flange connections

- no difficulty in replacing pipes having been deformed by high temperatures.

• Savings in assembly/ disassembly

- prefabrication of pipes requires less precision

- no adjustment work needed on the hose

- assembly inaccuracies are easy to correct

- only part of the line must be removed

- flexible elements are easier to remove and especially to re-install.

This results in:

- significant savings in assembly and disassembly of pipe systems

- higher flexibility in designing the pipe guides and in case of any modifications.

Name | Material Specifications | Operating Conditions |

Hose | AISI 316L-304L-321 S.Steel |

|

Braid Wire | AISI 304 Stainless Steel |

|

Connections | Carbon Steel-Stainless Steel | Flange /threaded/quick coupling/welding neck connection |

Working Pressure |

| 6bar to 25 bar |

Reinforcement Spring |

| -196℃ to +600℃ |

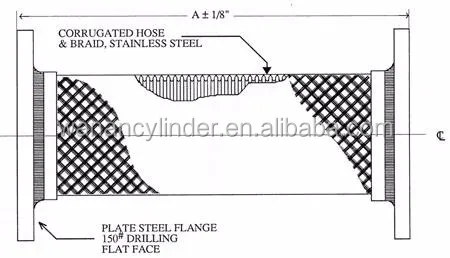

Construction of Flexible Metal Hose

Inner Core: Corrugated Stainless Steel

♥ Flexible metal hose stainless steel core strengths are available in 304, 321 and 316L stainless steel

♥ Stainless steel tubing formed into corrugations parallel to one another

♥ Helical / Convoluted option available upon request

Outer Core: Braided Stainless Steel Layers

♥ Purchase corrugated core hose with no layers, single or double braided

♥ Flexible metal hose outer braid layers made from 304 stainless steel

1. Metal bellows to absorb large axial displacement between straight tube and support frame, and small horizontal displacement;

2. To resolve minor deviation because of piping connection and eliminate the pipeline residual stress;

3. All of our metal bellows are easy to clean and maintenance.

4. The mesh is braided by 10 shares 304 ss wire, make its structure compacted, and acquire excellent torsion tension ability and high working pressure up to 1.6 Mpa.

1. Chemical analysis for material

2. Mechanical property testing for material

3. NDT will be carried out on all products

4. Pressure testing

5. Painting testing

6. Dimension and appearance quality inspection

7. Package inspection

To properly design a metal hose assembly for a particular application, the following design parameters must be determined.

1. Temperature:

You should provide us this information as the temperature to which the assembly is exposed a proper fit.

2. Size:

The diameter of the connections in which the assembly will be installed is needed to provide.

3. Media:

This is important since you must be sure that the assembly's components are chemically compatible with the media going through the hose as well as the environment in which the hose is installed.

4. Pressure:

Identify the internal pressure to which the assembly will be exposed. This information is important to determine if the assembly is strong enough for the application.

5. Identify the necessary end fittings.

This is required since fittings for the assembly must be chosen to properly fit the mating connections.

Q: How to pay express charges if order samples?

A: For those customers, who have DHL, FEDEX, TNT, UPS account, can give us your account and we will send the samples by freight collected. For those customers, who do not have an express account, we will calculate the express freight charge for you and you can pay the freight charge directly to our company account. Then we will deliver the samples of flexible metal hose by prepaid.

Q: How to pay sample charges?

A: You can pay to our company account. When we received the sample fee, we will arrange to make the samples for you. The prepare time for sample of flexible metal hose will be 3-7 days.

Q: How to order your items?

A: If you have the drawings of products like flexible metal hose, send them to us, we can production the items according to your drawings perfectly! If you not have drawings, please tell us the size, material, quantity, pressure, medium of the item you want, then our technical section will provide drawings for you to confirm the right specification. Finally make you satisfied!

Q: What’re services can you offer?

1. We offer OEM service and Free Sample.

2. We can design the right hose according to your application.

3. As manufacturer, we can offer reliable quality and reasonable price.

4. Accept small quantity order or trial order.

5. Good service before and in order and after sale.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.