KTC-838AC Automatic tension controller Tapper tension controller

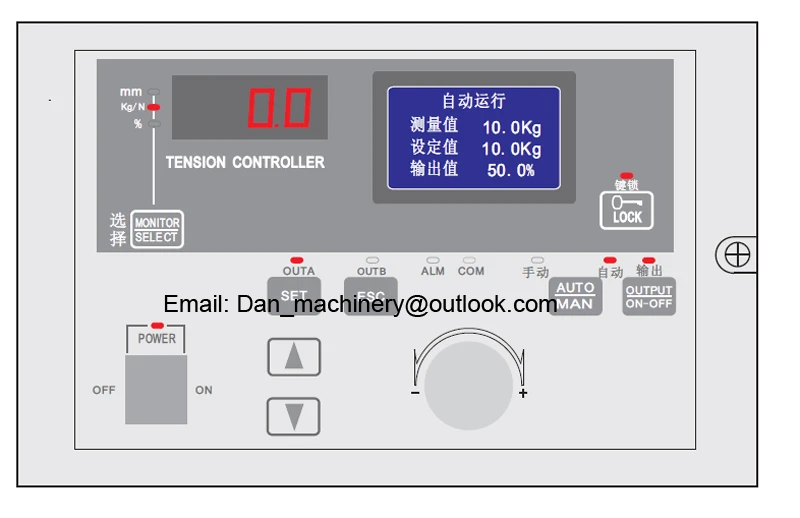

KTC838AC adopts the sketch liquid crystal display which shows the Chinese and English more clearly

and send out 0~24V/4A to drive the magnetic clutch/brake, or output 0~5V, 0~10V voltages signal to control

the frequency converter, servo motor or other actuators so as to perform the highly accurate control. It is

widely used in the industries of paper-making, printing, packing and textiles printing, etc.

KTC838AC can be set as full-automatic tension controller or radius tension controller. It is full-automatic

tension controller when system's mode [28]is set as automatic tension control and can be formed as a

closed-loop tension control system with installing tension transducer. It is radius tension controller when

system's mode [28]is set as radius tension control, it just needs to install the proximity switch/encoder to

measure the coiled materials' radius and perform the tension control according to the radius.

Chapter 4 mainly introduces the debugging and operation of full-automatic tension controller while

Chapter 5 mainly introduces the debugging and operation of radius tension controller.

FEATURES:

1.Adopt the 128X96 sketch liquid crystal displayer with choice of Chinese/English display and user friendly

operational interface.

2.Function of full-automatic tension controller or radius tension controller choosing.

3.Full-digital design, no adjustable , simple process of tension calibration, the tension

measurement is highly accurate, stable and reliable.

·Can receive the input signal of one-way/two-way transducer, adjust various tension transducer as input

signal

A.can choose the micro-displacement specialized tension transducer ( input signal range +-300m V,

5V power supply).

B.can choose strain gauge tension controller ( input signal range +-20m V, 10V power supply).

4.Adopt the proximity switch to measure the radius can realize the function of taper tension control.

5.Can choose the function of serial communication , also can choose the communication port of RS485 or RS232 to connect with PLC, PC to make up the distribution system.

6.Adopt no-overshot PID algorithm, guarantee no-over shot of tension during the process of system's

distributed control system.

7.Have the function of two-axel switching and acceleration/deceleration control.

8.Switch of automatic/manual control without interference.

9.Protect the password parameters, avoids mis-operation.

10 Adopt the switch power supply with strong adaptability (185~264V), guarantee long-term stable

operation.

potentiometer

11.[1]parameters of controller, the number in[]indicates the order number of the parameters, all the

parameters are indicated in this form.

Technical parameters:

|

Power supply |

AC165-264VAC 50/60Hz |

|

Input |

Single/double tension sensor signals ,single/double tension sensor signals Spindle pulse signal (compatible decoder signals and control contacts signal (MC1-MC6) Two input 0-10V analog voltage

|

|

Output (Control the output) |

Two output DC0-24V / A, for magnetic clutch / brake Two analog output 0-10V (or 4-20mA) Tension alarm output RS485, the standard Modbus communication interface |

|

Output (Auxiliary power supply) |

Tension sensor power supply (DC5V or DC9V) Proximity switch or coder power (DC24V) AIN1, AIN2 two analog input channel power (DC10V) |

|

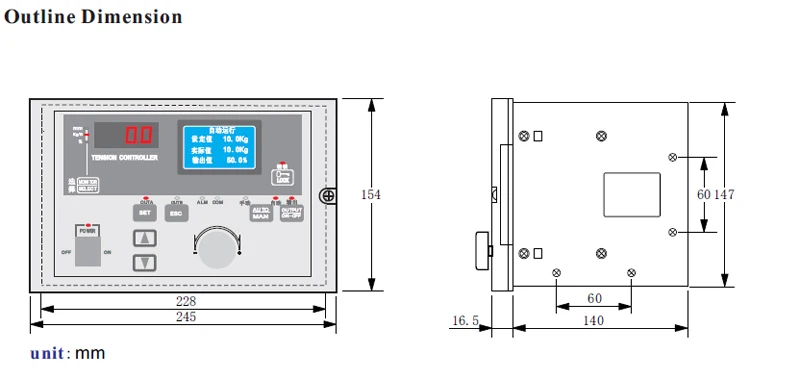

Dimension |

245(W) x 154(H) X 156.5 (D) mm |

Application

It is widely used in the industries of printing, packing, paper-making, cable, rubber, electron battery and textiles printing.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.