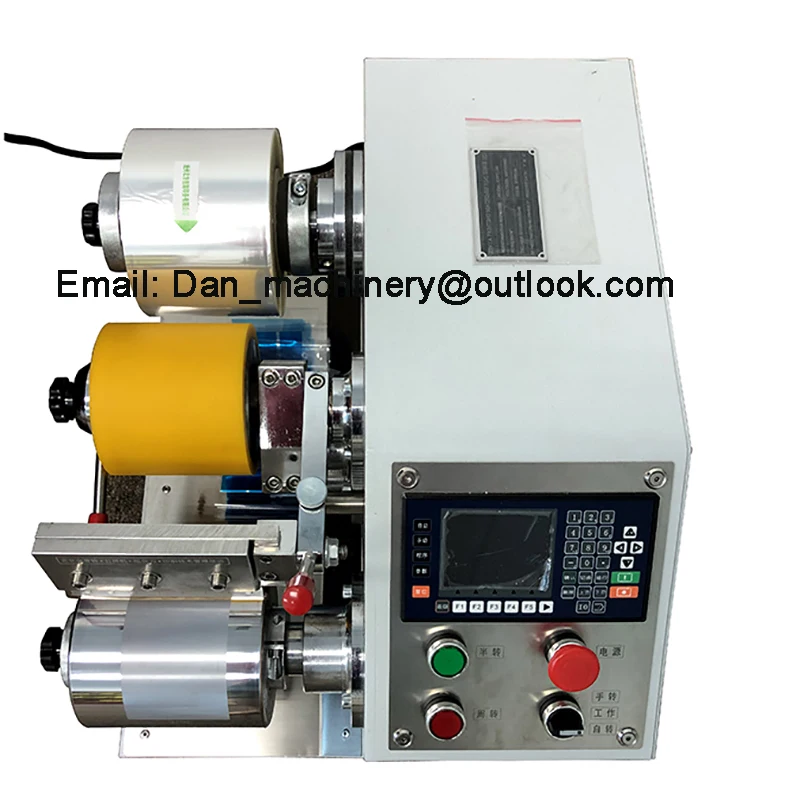

Ink Printing proofer for gravure and flexo printing

The proofing machine adopts LCD display, CNC motor drive, integrated structure of

control system, synchronous belt drives the plate roller spindle mechanism, all

control parameters and measurement data can be displayed and adjusted on the

LCD screen in real time, and it has reliable accurate repeat positioning And

other functions.

Main technical parameters

1. The voltage is 220V±10%.

2. Maximum speed: 300 rpm

(adjustable).

3. The designated number of

rotations: 1/2 or arbitrarily settable.

4. Rotation accuracy: 0.1 degree.

5. Liquid crystal display content:

technical indicators such as speed, lap accumulation, etc.

6. Host weight: about 90Kg.

7. EPDM (silicone

roller/polyurethane etc./optional) hardness 65 degrees.

8. Packing size of proofing machine:

650*550*450mm

The working conditions of the proofing

machine

1. In the room temperature range of

10℃-35℃, the relative humidity

is not more than 80%.

2. On a stable foundation or

workbench, correctly install and check the levelness.

3. In a vibration-free environment.

4. There is no corrosive medium

around.

5. The fluctuation range of 220V

power supply voltage should not exceed ±10% of the rated voltage.

5. Institutional introduction

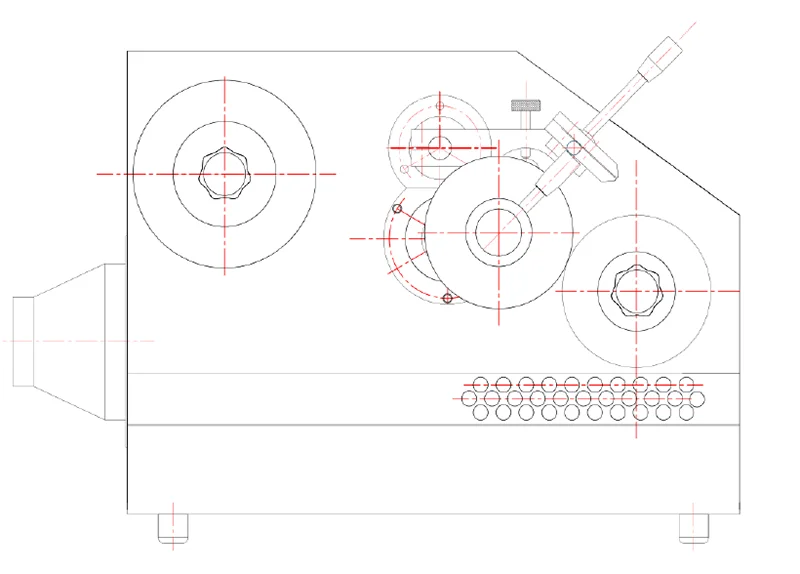

The proofing machine is composed of

a host, an electrical controller and accessories, see the attached drawings for

details

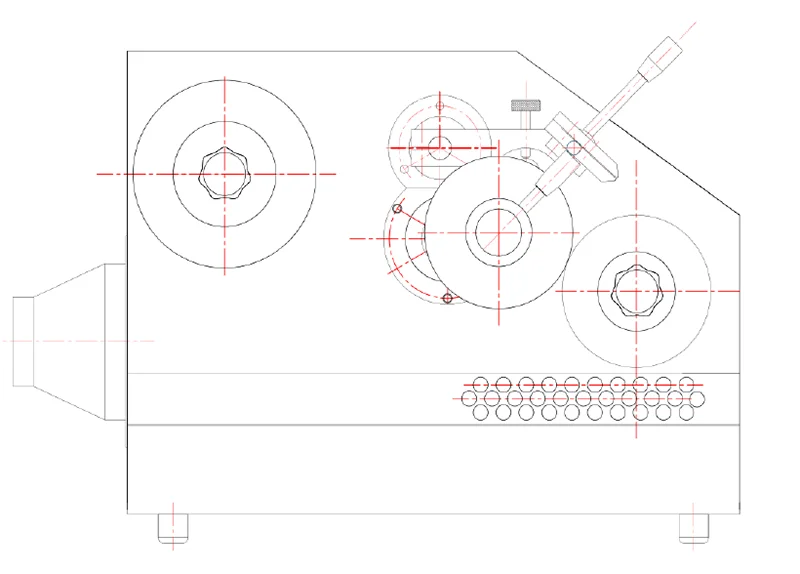

1. Host part

The main machine is divided into

five parts: unwinding part, pressure roller part, ink scraping part, plate

roller part, exhaust gas centralized storage and discharge part.

A.

The unwinding part adopts the combination of friction plate and spring to form

an effective constant tension to ensure that the unwinding tension can be

adjusted and maintained

B.

The pressure roller part adopts silicone rubber roller, which effectively

extends the life of the rubber roller.

C.

The squeegee part adopts the perfect combination of aluminum alloy splint, Swiss

imported combined knife holder and Swiss ZOC-LL long-life small gold knife,

which reduces the loss of squeegee and improves the convenience of squeegee

assembly and disassembly.

D. The plate roller part adopts

customized high-precision plate roller and professional layout design, which

highlights the professional level and craftsmanship of the enterprise.

E.

The exhaust gas centralized storage part uses a high-speed fan to effectively

store and discharge the solvent during sampling, and it can be connected to the

exhaust pipe

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.