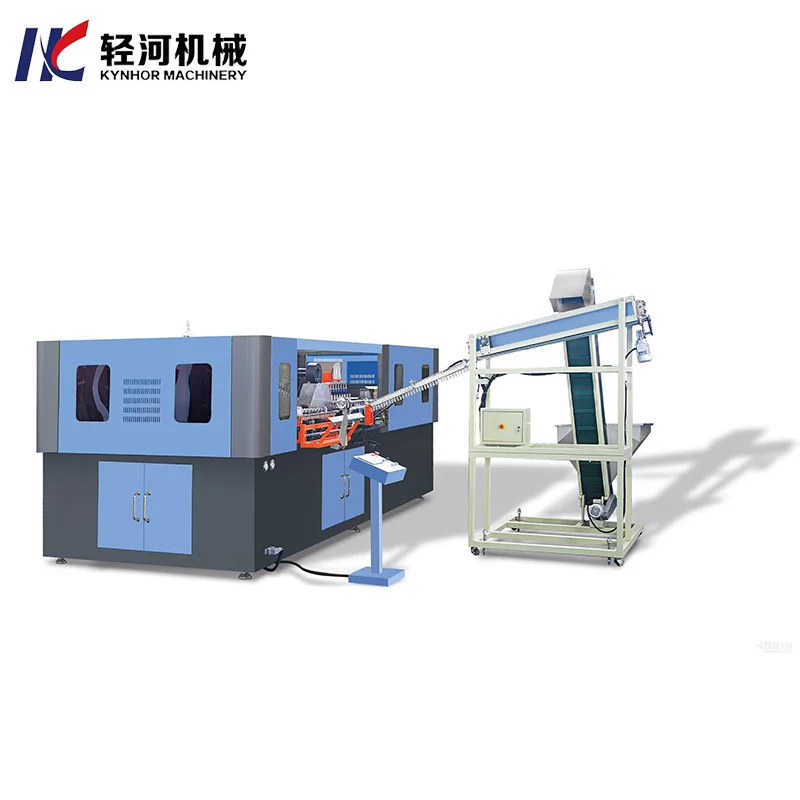

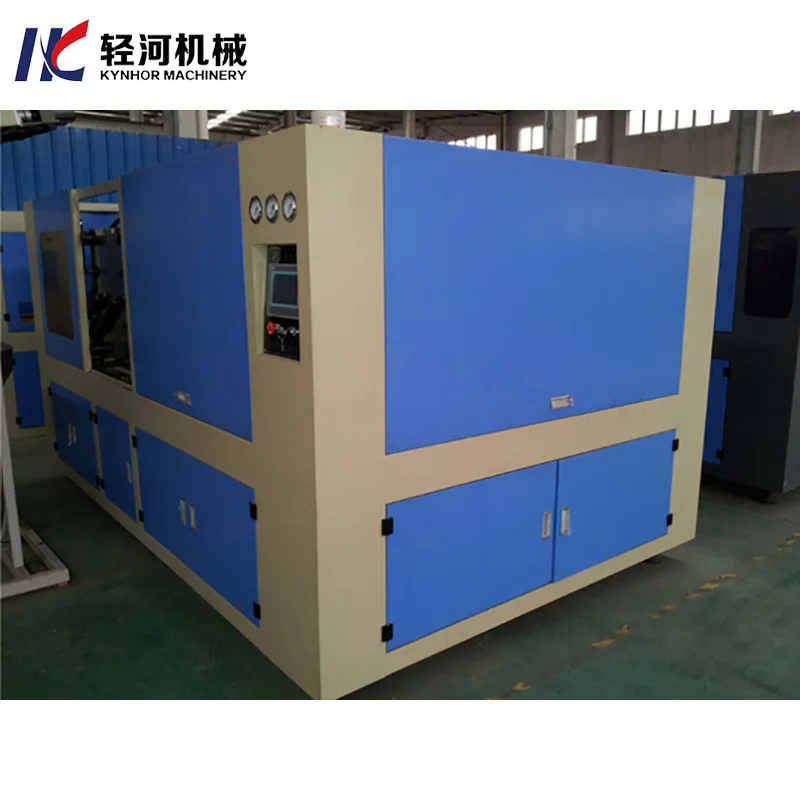

Hot sale pet plastic bottle blowing making machine in China

Craft Flow

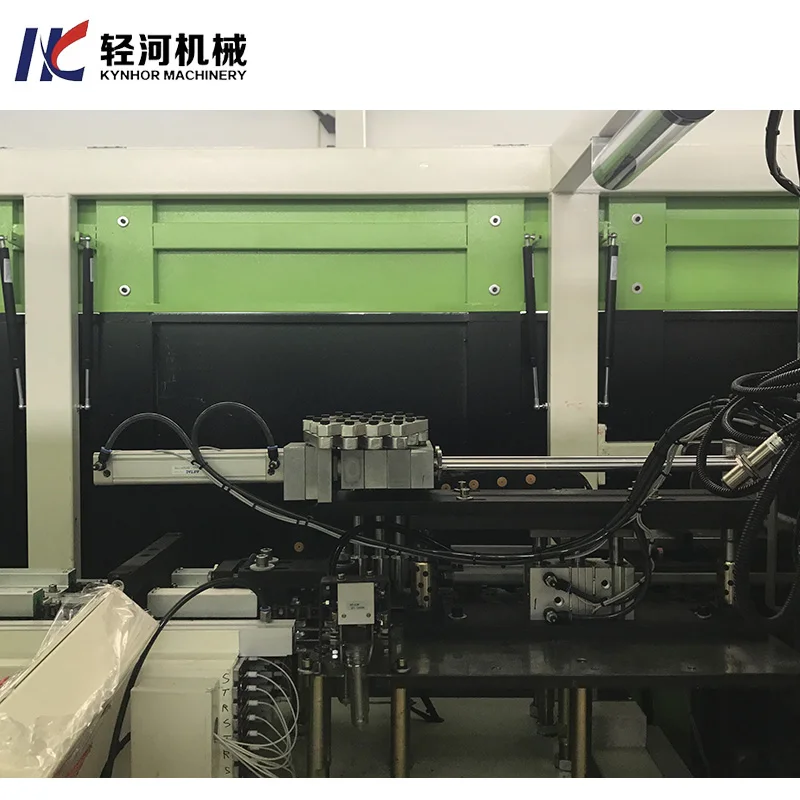

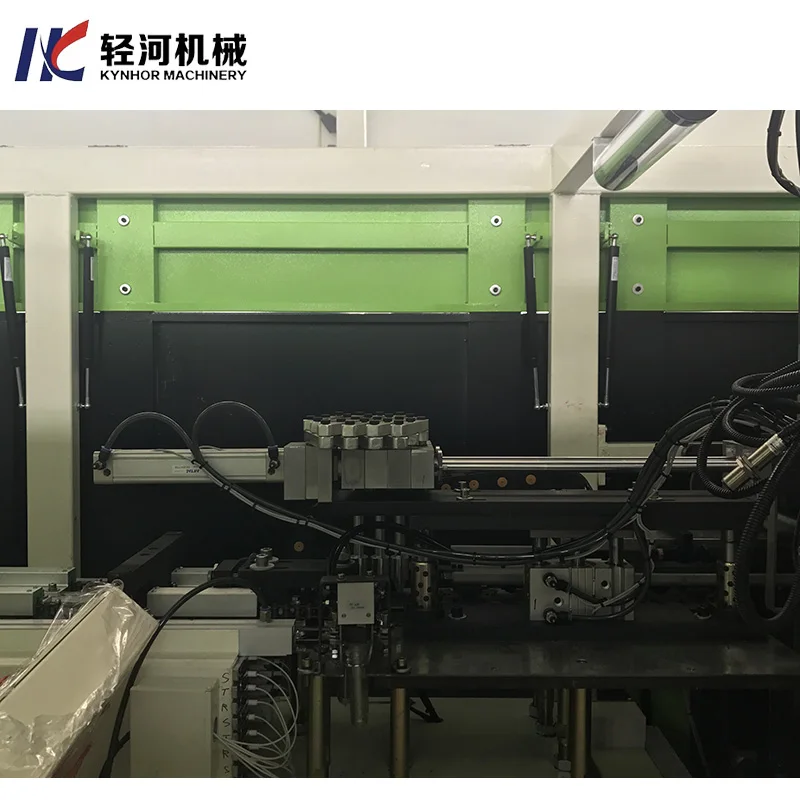

Preform→Preform storing parts→Preform heating(temperature adjustment) →(Pull stretch→Blow air→ Release Air→ Blow pin and mouth at same time→Close the blow mouth→Forming)→Finished

Brief Introduction

GR6-A Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used for producing the carbonated bottle, mineral water bottle, pesticide bottle, oil bottle, cosmetics bottle, wide-mouth bottle and hot filling bottle etc.

Settings:

1).PLC display: Siemens

2).Pneumatic and valve parts: SMC

3). Operating system: Siemens

4) Relay: OMRON

5).Other electric parts are all world-famous brand

Configurations:

Items | Brand | Origin |

air-break switch | Mitsubishi | Japan |

relay | Japan | |

option switch | Schneider | France |

green directive button | France | |

emergency stop switch | Schneider | France |

normally open contact | Schneider | France |

normally closed contact | Schneider | France |

photoelectric switch | OMRON | Japan |

travel switch | OMRON | Japan |

proximity switch | Japan | |

photoelectric switch | OMRON | Japan |

transducer | FULIN | China |

touch screen | Siemens | Germany |

PLC | Siemens | Germany |

Technical Parameter:

Model | OK2-A | |

Productivity | Depend on bottle design | 2000PCS/H |

Product type | Body diameter | ≤90mm |

Height | ≤310mm | |

Neck diameter | ≤30mm | |

Mold | Cavity | 2cavities |

Main machine power | Electrical source power | 380v 3Phase 50HZ |

Rated Power | 30kw | |

Really use power | 12kw | |

Air source | LP air compressor | 2.0m3/MPa |

HP air compressor | 1.0m3/Mpa | |

|

| |

Air dryer | 2.0m3/Mpa 3.0MPa | |

Cooling water | Cooling water | 10L/min |

Size | L*W*H | 4000*2000*2200mm |

Weight | 3000kg | |

Auxiliary equipment(preform unscrambler) | L*W*H | 2300*1500*2480mm |

Weight | 350kg | |

Resin available |

| PET |

How to trust us!

1.Kynhor cooperates with Alibaba who will supply you a lot of service to protect you .

2.Kynhor is registered in the Chinese business administration and has the right to operate and sell it legally.

3.Kynhor has a professional engineer team who all have more than 15 years experience in beverage filling machine manufacturing .

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station or the airport near our city.

3.If we get the permission of the customer who has brought the machines from us,we can tell you our customers' contact information,you can go to visit their factory.

4.We provide you with free debugging .

Customized service

1.We can design the machines according your requirements(material,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

2. We can offer free technical support and consultation such as design your factory,draw the factory layout and so on.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty with spare parts free and life-long technical support .

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.