Zhuohangxin Metal uses high-quality molybdenum powder to process it into slabs with excellent performance. It uses special rolling technology to produce a series of molybdenum plate (molybdenum sheet) products with the advantages of good processing performance and smooth surface.

MO1, MLa

Standard: ASTM B386-91,

Purity: pure molybdenum Mo1≥99.95%, molybdenum-lanthanum alloy MLa (lanthanum content 0.4-0.8%)

Density: ≥10.2g/cm3

Applicable environment and maximum applicable temperature: pure molybdenum within 1400℃, molybdenum-lanthanum alloy within 1800℃ under vacuum or inert gas protection environment.

Surface classification: 1) Hot-rolled alkali-washed surface 2) Cold-rolled bright surface 3) Polished surface

Supply state: hard or soft

Supply specifications:

Foil: thickness 0.025-0.09mm, width 30-100mm, length > 500mm

Sheet: thickness 0.09-0.5mm, width 30-600mm, length 30-2500mm

Plate: thickness 0.5-10mm, width 50-680mm, length 50-2500mm

Block: thickness > 10mm, width > 20mm, Length>20mm

Process flow: hot rolling blanking--stress relief annealing--warm rolling--stress relief annealing--alkali washing--first cold rolling--stress relief annealing--second cold rolling--stress relief annealing--finished product cold rolling annealing--cutting--inspection and storage

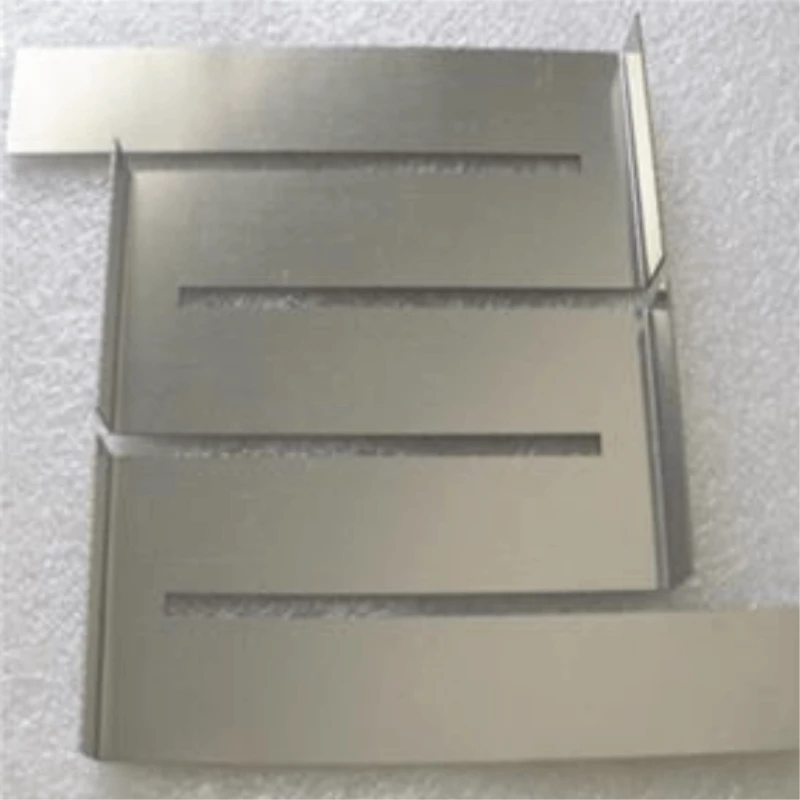

Application: After rolling processing with a deformation of more than 60%, the density of the molybdenum sheet is basically close to the theoretical density. Therefore, it has high strength, uniform internal structure and excellent high-temperature creep resistance. It is widely used in the production of reflective screens in sapphire crystal growth furnaces, reflective screens in cover vacuum furnaces, heating belts, connectors, sputtering targets for plasma coating, high-temperature boats and other products.

Cold-rolled thin plates are mainly used in electric vacuum and electric light source industries. Thin molybdenum plates are processed into products of various shapes and specifications through secondary forming processes such as deep drawing, drawing, and spinning, such as molybdenum crucibles, sintered boats, high-power emission anodes, and grid molybdenum cylinders. With the development of modern high-temperature ceramics and electronics industries, the demand for cold-rolled molybdenum plates has increased, and the quality requirements are very strict.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.