working principle

SLA is an abbreviation for "Stereo lithography Appearance", that is, stereo photocuring.

Focusing on the surface of the photocurable material with a laser of a specific wavelength and intensity, from point to line, from line to surface solidification, complete a level of drawing operation, then move the lifting table vertically in the height of a layer, and then solidify On another level, such layers are superimposed to form a three-dimensional entity.

crafting process

SLA is the first practical rapid prototyping technology, using liquid photosensitive resin raw materials. The process is to first design a three-dimensional solid model through CAD, use a discrete program to slice the model, design the scan path, and the generated data will precisely control the motion of the laser scanner and the lifting platform; the laser beam is controlled by the numerical control device. The surface of the liquid photosensitive resin is irradiated according to the designed scanning path to cure a layer of resin in a specific area of the surface. When a layer is processed, a section of the model is formed; then the lifting platform is lowered by a certain distance, and the solid layer is cured. Covering another layer of liquid resin, and then performing a second layer scanning, the second solidified layer is firmly bonded to the previous solidified layer, so that the layers are superposed to form a three-dimensional workpiece prototype. After the prototype is taken out of the resin, the final curing is carried out, and then the desired product is obtained by polishing, electroplating, painting or coloring.

| SLA light curing laser 3D printer equipment parameters | |||||

| Technology type: laser curing, layered manufacturing | |||||

| Material Type: Photosensitive Resin | |||||

| Number of lasers:Variable laser 1 pc | |||||

| Laser system | |||||

| Laser type: solid state laser Nd:YVO4 | |||||

| Wavelength: UV λ = 355nm | |||||

| Lowest power: forming power 350mw (actual) | |||||

| Optical scanning system: spot (diameter @1/e 2 ) 0.10-0.12mm | |||||

| Scanning form: RTC4 Scancube14 (import) | |||||

| Part scanning speed: recommended 6.0m/s | |||||

| Part jump speed: 10.0m/s recommended | |||||

| operating system | |||||

| Industrial computer operating system Windows 7 and above | |||||

| Control Software Slice Software: Materialise 15.0 (optional) | |||||

| Control system: Storm4.0 | |||||

| Data format: STL file | |||||

| Dongle: 1 copy | |||||

| Coating system | |||||

| Coating method: intelligent positioning vacuum adsorption coating | |||||

| Normal layer thickness: 0.1mm | |||||

| Quickly make layer thickness 0.125mm | |||||

| Precision production layer thickness 0.075mm | |||||

| Lifting system | |||||

| Vertical resolution 0.0002mm | |||||

| Repeat positioning accuracy ±0.01mm | |||||

| Maximum production part weight 55 kg | |||||

| Resin tank | |||||

| Resin heating PTC heating | |||||

| Installation condition | |||||

| Power supply 200-240VAC 50/60Hz, single phase, 15Amps | |||||

| Ambient temperature 20-26oC | |||||

| Relative humidity below 40%, no frost knot | |||||

| Equipment size | |||||

| 1220mm (W) × 1297mm (D) × 1898mm (H) | |||||

| The weight of the equipment is about 550kg | |||||

| Warranty | |||||

| Laser 5000 hours or 12 months (whichever occurs first) | |||||

| The whole machine starts from the installation date for 12 months. |

- Packaging Details

- Sponge+specification+parts+Honeycomb Cardboard Box+Carton+wood pallet

.

- Delivery Time

- 3~15days

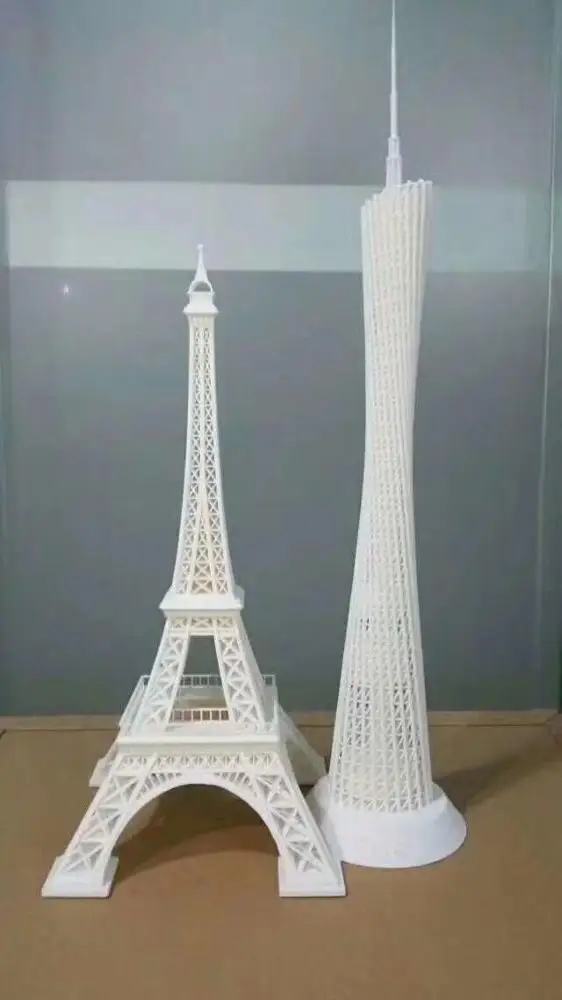

- Gallery(Pictrue by moble hpone)

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Contact us

Contact: Cicie Wong

Mobile: 0086 17351972197

Email: bairen3datqq.com(at means@)

What'sapp: 17351972197

Please feel free to contact us if any question.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.