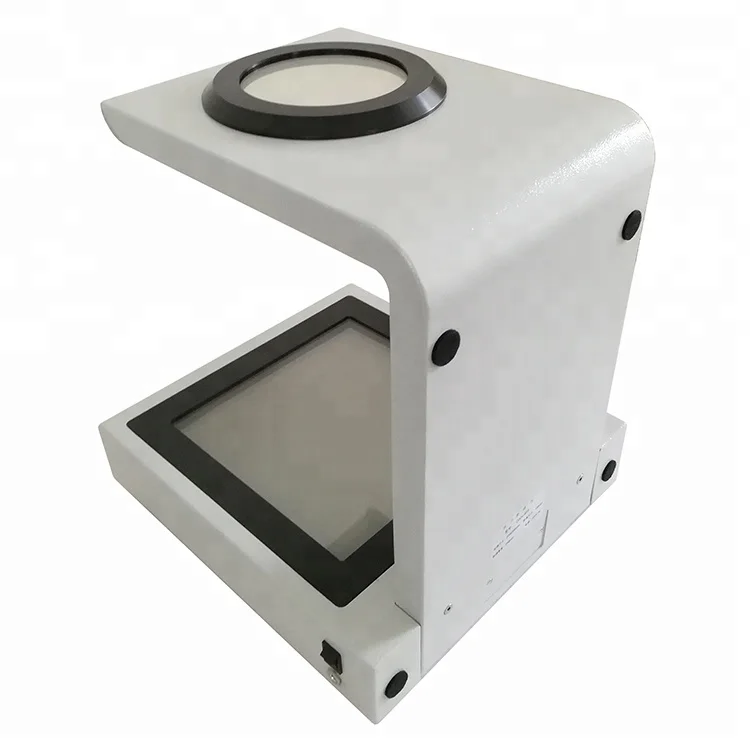

High Quality DAN 402 glass products Stress tester glass stress meter detector FREE SHIPPING

High Quality DAN 402 glass products Stress tester glass stress meter detector

Use and profile

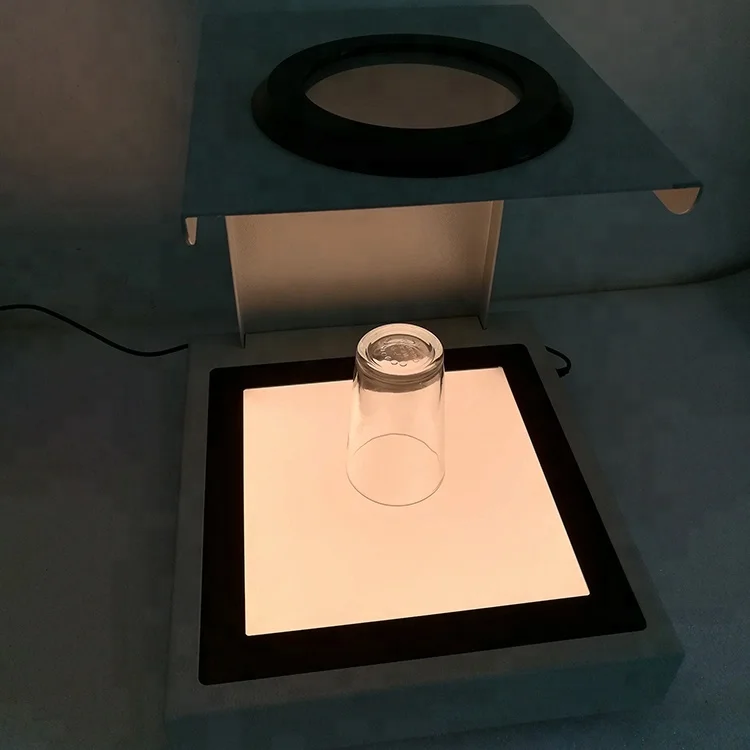

402 Glass Product Stress Tester is an instrument used to check the stress and distribution of stress in a transparent object. Through the measured transparent objects, the instrument can quickly and continuously analyze the glass or other transparent objects within the stress situation. 402 glass products stress tester can be horizontal or vertical angle of the glass and plastic accessories for testing, and more for quality control management testing. The measurement method is mainly measured by holding the measured object under polarized light. 402 have plenty of space to use for a variety of products to measure.

Technical Parameters

1. Polarizer: 200 x 200mm

2. Extender: diameter 100mm

3. Measuring height: 233mm

4. Product Size: 300 * 300 * 400mm

5. Light source: imported fluorescent lamp

Configuration

1,402 stress tester body has 2 pairs of rubber shock pad feet, easy to operate from the horizontal or vertical direction, the use of vertical placement. The

2, the standard configuration includes: a light source, a built-in full-wave plate, a quarter-wave with a parser, a polarizer with a quarter-wave plate.

Instructions

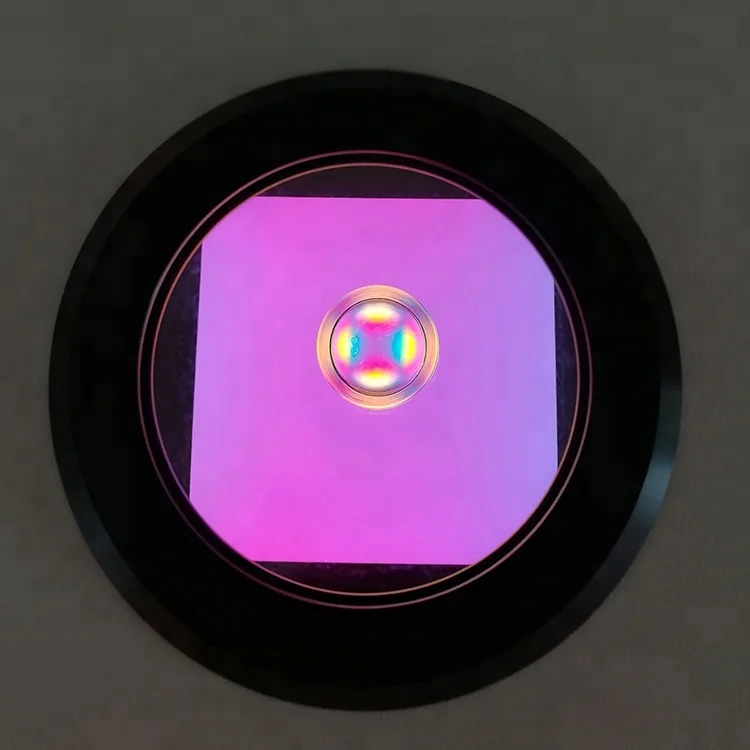

1, the stress of glass and plastic products has birefringence characteristics. The stress of such a product can be divided into different components of each light of the polarized light, which in turn produces an optical interference to produce a corrugated pattern. In the white light, this pattern consists of color ripples, from the measured sample pattern difference can be observed two main stress.

2,402 Through the observation of the pattern and color, to measure the glass products before and after the annealing stress, and then measure the work of the annealing equipment. Qualified standards are generally developed by the manufacturer.

3, the detection of plastic abrasive is more complex, stress generated by the irregular patterns. Glass products will be a similar situation, which is called the phenomenon of stress stretching.

4, the role of the whole disc or color wave plate: in the detection of glass samples, if not using the full disk, usually only see the black or gray pattern. The full disc is increased or decreased by a phase difference of the full wavelength, thus forming a color pattern, easier to reason and explain

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.