Gravure Printing Proofing Machine DAN-1400

printing Cylinder length | 200-1400mm (as your request) |

Printing Cylinder diameter | Diameter 85-400mm(as your request) |

Rubber roller diameter | 900mm (as your request) |

Rubber cylinder length : | 1400mm |

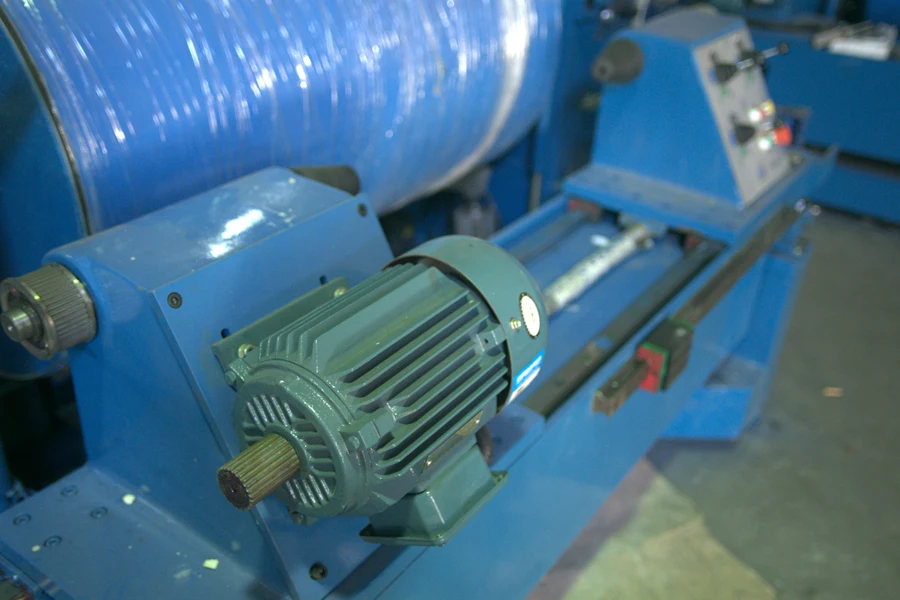

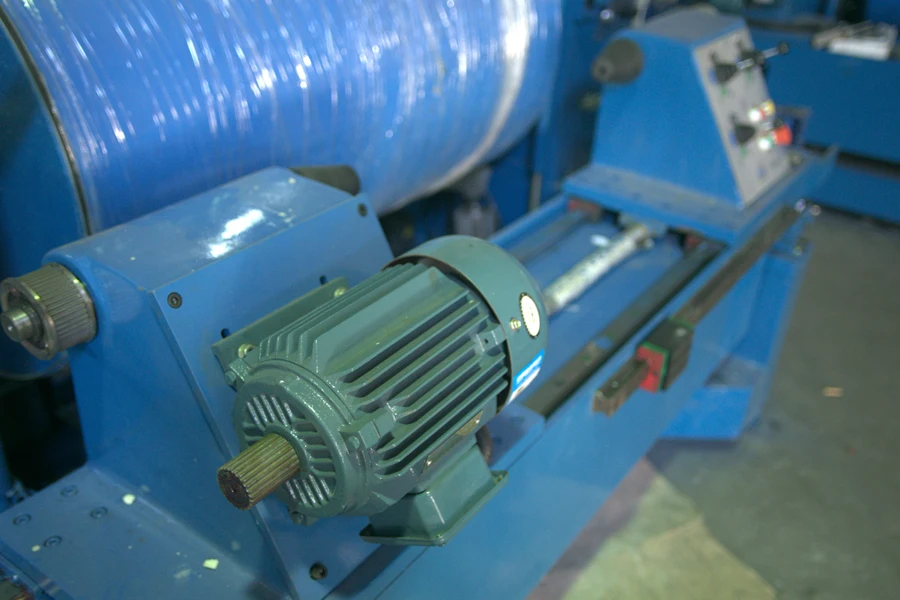

Drive power | 3kw |

Proofing Speed | 0-50M/min(adjustable) |

Power modes | hydraulic pressure |

Dimension (L xW x H)CM | 2400x1700x1600 |

Weight | About 4000KG |

install-nip type cylinder drive

1.Printing cylinder Using taper top tight top, top with a diameter of diameterd70mm and 110mm two kinds each set for a top tapered hole d50-100mm Diameter

2. Clamping is 0.37kw reducer tailstock move directly clamped.

3. Cylinder driven by 3kw motor frequency control

roller part

1. High-quality steel welding, precision grinding

2.Highly granular rubber

3. Starting position hydraulic top tight to ensure positioning accuracy

4. Automatic positioning device.

5. Precision linear guide

6. Front and back moving hydraulic top tight.

Lathe Frame

1. Welded steel frame, surface rust treatment

2. Precision V-shaped guide

3. Precision screw, wire mother.

4. High-precision, high-expansion magnifying glass.

5. High-resolution display

6. Adjustable Doctor Blade Device

Electrical apparatus

1.Main motor 3kw, ( frequency control)

2. Tailstock mobile 0.37kw turbine worm reducer

3.Doctor blade move hydraulic control vertical and horizontal directions.

Features: DAN-1400 proofer use the British proofer structure. British proofing structure is relatively more accurate than the Japanese proofer structure. Because British proofer use the big rubber tire drive gear , can effectively prevent the plate cylinder and rubber roller drive slip phenomenon, affecting the printing accuracy.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.