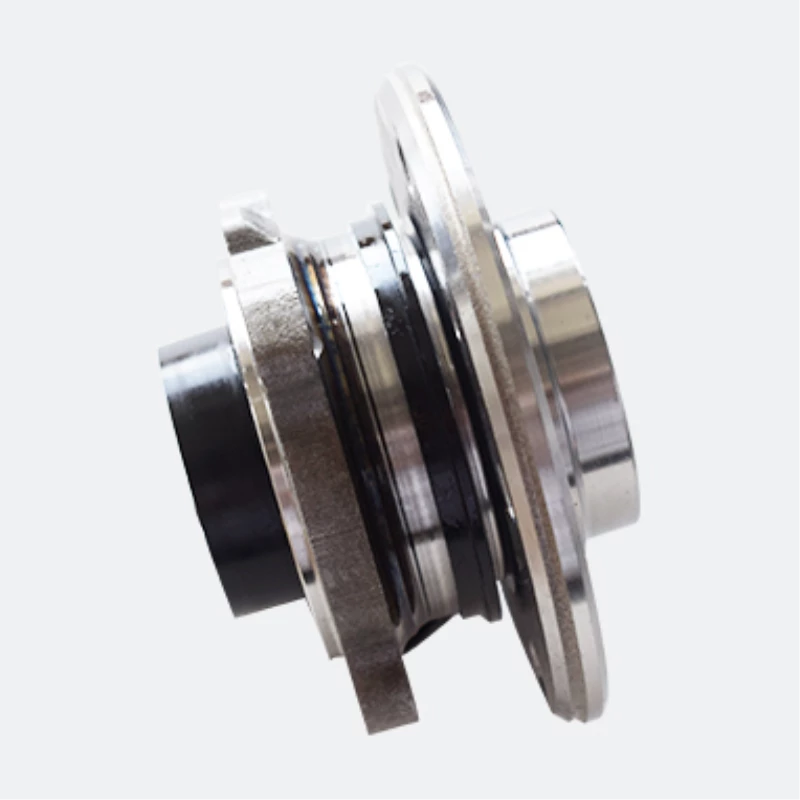

1. The working principle of wheel hub bearings According to the structure, wheel hub bearings are divided into first, second and third generation wheel bearings. The first generation of wheel hub bearings are mainly composed of inner ring, outer ring, steel balls, and cage. Its working principle is shown in Figure 1. The working principle of the first, second and third generation wheel bearings is similar to that of ordinary bearings. They all use steel balls to roll in the inner ring, outer ring or flange raceway, load and rotate relatively, so that the car can drive.

2. Abnormal sound of wheel bearing

1. Abnormal noise characteristics of wheel bearings

According to the working principle and force characteristics of the hub bearing, its abnormal noise has three important characteristics: ①The hub bearing rotates with the wheel, and the frequency of the abnormal noise is proportional to the wheel speed. As the vehicle speed increases, the abnormal noise of the wheel hub bearing continues to become stronger, and the abnormal noise generally does not occur only in a certain narrow speed section. ②The abnormal noise intensity of the wheel hub bearing is proportional to the load it bears. When the car is turning, the wheel hub bearing bears a relatively large load, and the abnormal noise is more obvious. ③The abnormal noise of the wheel hub bearing is easily confused with the abnormal noise of the transmission system such as tires, engines, transmissions, transmission shafts, and universal joints.

2. The form of abnormal sound of wheel bearing

The main abnormal noise manifestations of hub bearings are as follows:

(1) Buzzing sound

When the internal raceway of the wheel hub bearing has defects such as wear, peeling, and indentation, or the bearing is loose, it will continue to produce "grunting" and "buzzing" abnormal noises. As the vehicle speed increases, the periodic grunting gradually turns into a humming sound, and eventually turns into a high-frequency whistling sound when driving at high speed.

(2) Squeak

When the hub bearing seal fails and the amount of internal lubricating grease is insufficient, the grease cannot form an oil film on the surface of the channel and the steel ball, causing the channel and the surface of the steel ball to contact and rub, resulting in a sharp squeaking sound.

(3) Gaps

When there are bumps on the surface of the steel ball inside the bearing, the steel ball is chipped, or there is a hard foreign body inside the bearing, the steel ball crushes the abnormal part of the raceway during the driving process, causing a "gawking" abnormal sound.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.