full automatic hard confectionery candy production line / double color hard candy production line/kopiko candy making machines

FUDE CGD series advance hard candy depositing line

Advantage of the servo driven compare with the mechanical driven

1. All the controls and operations are available in the PLC and touch screen.

2. Deposited candy weight can be set or adjusted in the touch screen easily.

3. More accurate for depositing quantity control.

4. Operate, maintenance and CIP service will be easier.

5. More steady Running and less vibrating, less noise.

6. High efficiency working can gain more benefit and save the man power, prolong the machine life.

7. Simple structure makes the operation and maintenance easier. Etc….

FEATURES:

The processing line is a compact unit which can continuously produce various kinds of hard candies under a strict sanitary condition. It is also an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied.

1) PLC /computer process control available;

2) An LED touch panel for easy operating;

3) The standard production capacity is300/450kgs/h;

4) The main parts is made of hygienic Stainless Steel

5) Syrup masses flowing controlled by Frequency inverters ;

6) In-line injection, dosing and pre-mixing techniques for the proportional addition of liquid;

7) Dosing pumps for the automatic injection of colors, flavors and acids;

8) Use AUTOMATIC STEAM CONTROL SYSTEM instead of manual steam valve which controls a stable steam supply to the microfilm cooker;

9) “two-color stripe depositing”, “two–color double layers depositing”, “central filling”, “clear” hard candies and etc. can be made.(option)

10) Moulds can be made according to the candies samples provided by the customer.

Technical parameters:

Model | CGD150S | CGD300S | CGD450S | CGD600S | CGD1200S |

Output(kg/h) | 150 | 300 | 450 | 600 | 1200 |

Candy weight | As per the candy size. | ||||

speed | 55~60 n/min | 55~60 n/min | 55~60 n/min | 55~60 n/min | 55~60 n/min |

Steam consumption Steam pressure | 150kg/h, 0.5~0.8MPa | 300kg/h, 0.5~0.8MPa | 400kg/h, 0.5~0.8MPa | 500kg/h, 0.5~0.8MPa | 1000kg/h, 0.5~0.8MPa |

Compressed air consumption Compressed air pressure | 0.2m3/min, 0.4~0.6MPa | 0.2m3/min, 0.4~0.6MPa | 0.25m3/min, 0.4~0.6MPa | 0.3m3/min, 0.4~0.6MPa | 0.45m3/min, 0.4~0.6MPa |

Electric power needed | 18kW/380V | 27kW/380V | 34kW/380V | 42kW/380V | 68kW/380V |

Total length(m) | 17 | 17 | 17 | 17 | 19 |

CANDY SAMPLES MADE ON CGD MACHINES:

Striped candies/fruit flavour Clear candy Butter Scotch / Milk Candy

Central-filled Scotch with chocolate filled

Candy mould:

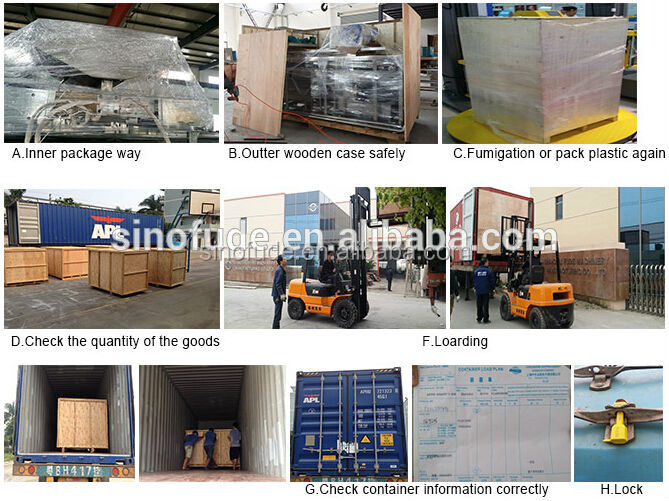

1.Wa are factory so all the machine can be customized and price will be more competitive .

2.All parts contact with food are stainless steels.

3.Free plant layout design, assembling and installation,engineer can go to local for team training and instal/ start-up.

4.The seller guarantees the quality of the products for 12 months since the date of installation.

5.Good and detailed pre-sale services and forever after-sales.

I promise bring the best service to every customer,and forever after-sales.

Shanghai fude machinery factory

www.sinofude.com

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.