|

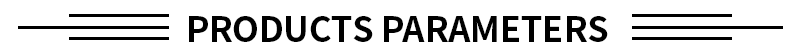

Specification (mm) |

Inner Diameter (mm) |

Outer Diameter (mm) |

Wall Thickness (mm) |

Positive and Negative Tolerance (mm) |

Hardness |

|

2*4 |

2 |

4 | 1 | 0.05 |

30-80A |

|

3*5 |

3 | 5 | 1 | 0.05 |

30-80A |

|

4*6 |

4 | 6 | 1 | 0.05 |

30-80A |

|

5*8 |

5 | 8 | 1.5 | 0.05 |

30-80A |

|

6*9 |

6 | 9 | 1.5 | 0.05 |

30-80A |

|

7*10 |

7 | 10 | 1.5 | 0.05 |

30-80A |

|

8*12 |

8 | 12 | 2 | 0.1 |

30-80A |

|

9*13 |

9 | 13 | 2 | 0.1 |

30-80A |

|

10*14 |

10 | 14 | 2 | 0.1 |

30-80A |

|

12*16 |

12 | 16 | 2 | 0.1 | 30-80A |

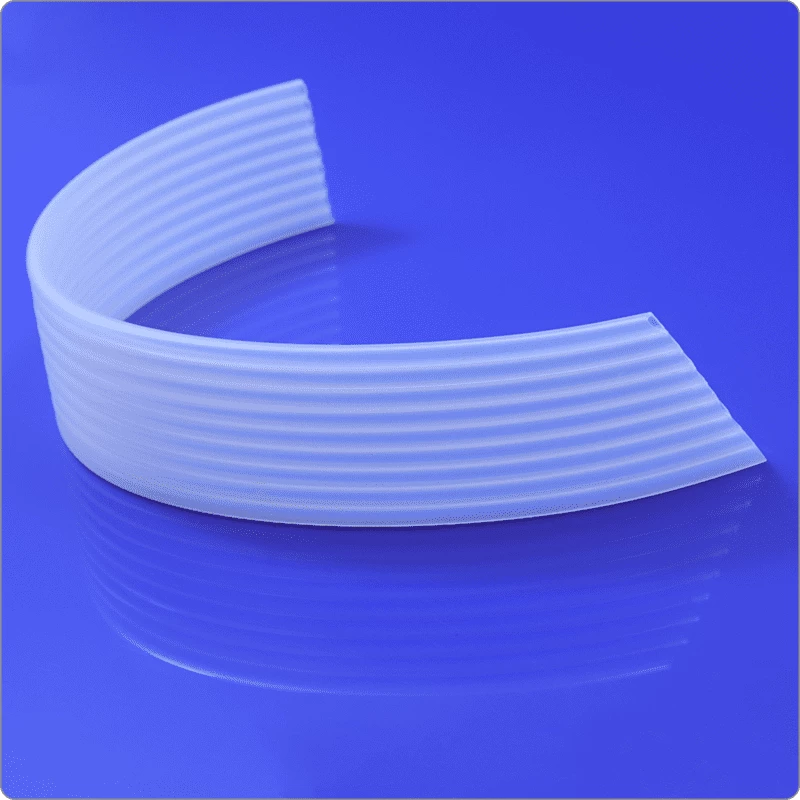

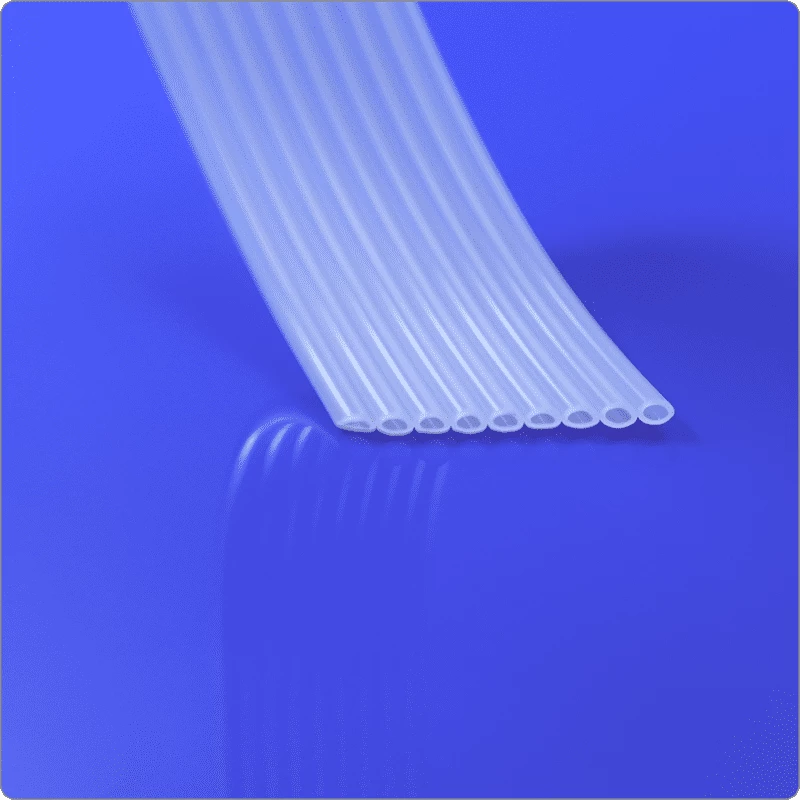

Multiple rows of silicone tubes:

The multi-row porous transparent silicone tubes connected together are produced by Shenzhen Jiajie by two production processes of silicone extrusion and molding. Extruded products include silicone sealing strips, silicone tubes, led silicone sleeves, etc. There are mainly kinds of display screen sealing rings and foamed silicone products, but foamed silicone strips, foamed silicone tapes and other products belong to extrusion process type, and foamed silicone pads and foamed silicone sheets belong to molding process products.

Multi-row silicone tube performance:

1. Non-toxic, tasteless, high transparency;

2. Strong resilience, resistance to compression and permanent deformation;

3. Excellent high temperature and low temperature resistance, good physiological stability;

4. Soft, arc-resistant and corona-resistant, various specifications can be customized according to customer requirements

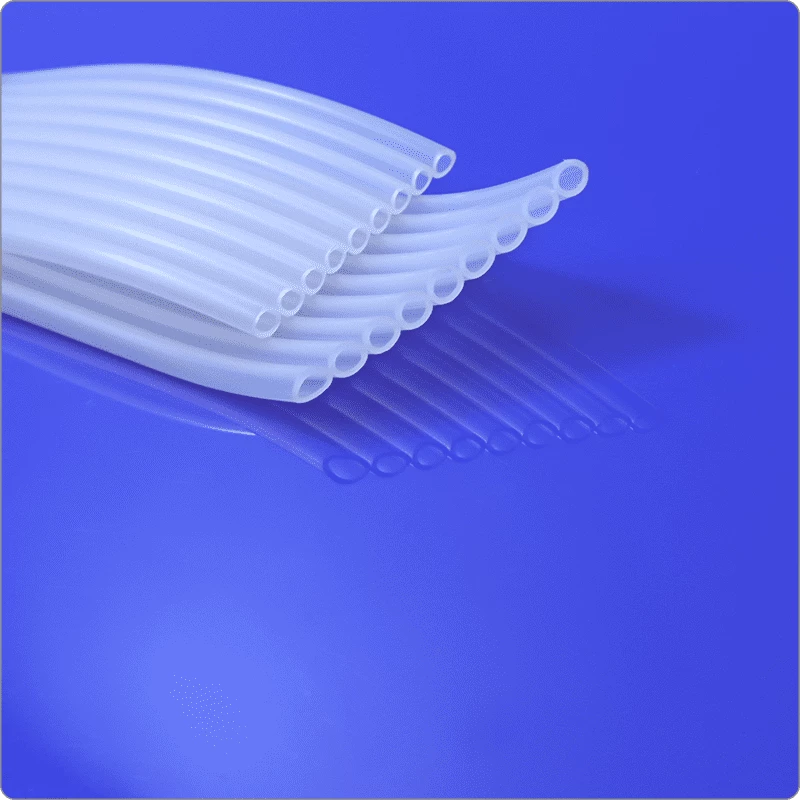

Multi-row silicone tube application:

Oxygen pipes, water flow pipes, various medical pipes, drainage pipes, transportation, industrial applications of silicone rubber, instruments, and instrumentation industries, etc.

![]()

.jpg)

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.