- Categories

- Electronics Product

- Beauty / Personal Care

- Furniture / Building Materials

- Automotive Machinery

- Ladies clothing

- Home Department Store

- International Logistic Service

Electronics Product

Electronics Product

Beauty / Personal Care

Beauty / Personal Care  Furniture / Building Materials

Furniture / Building Materials  Automotive Machinery

Automotive Machinery  Home Department Store

Home Department Store  International Logistic Service

International Logistic Service Description

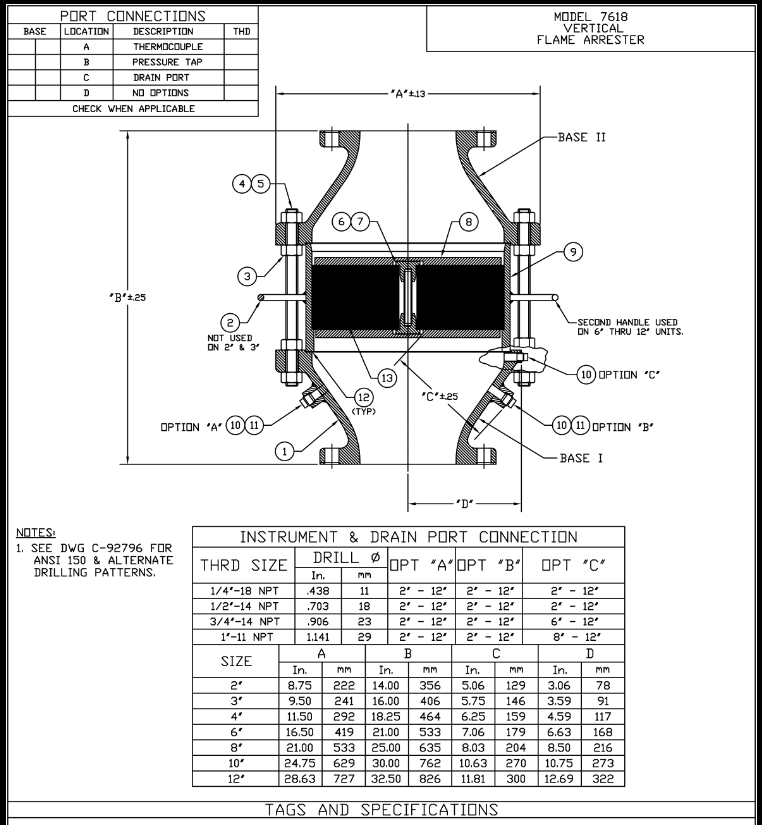

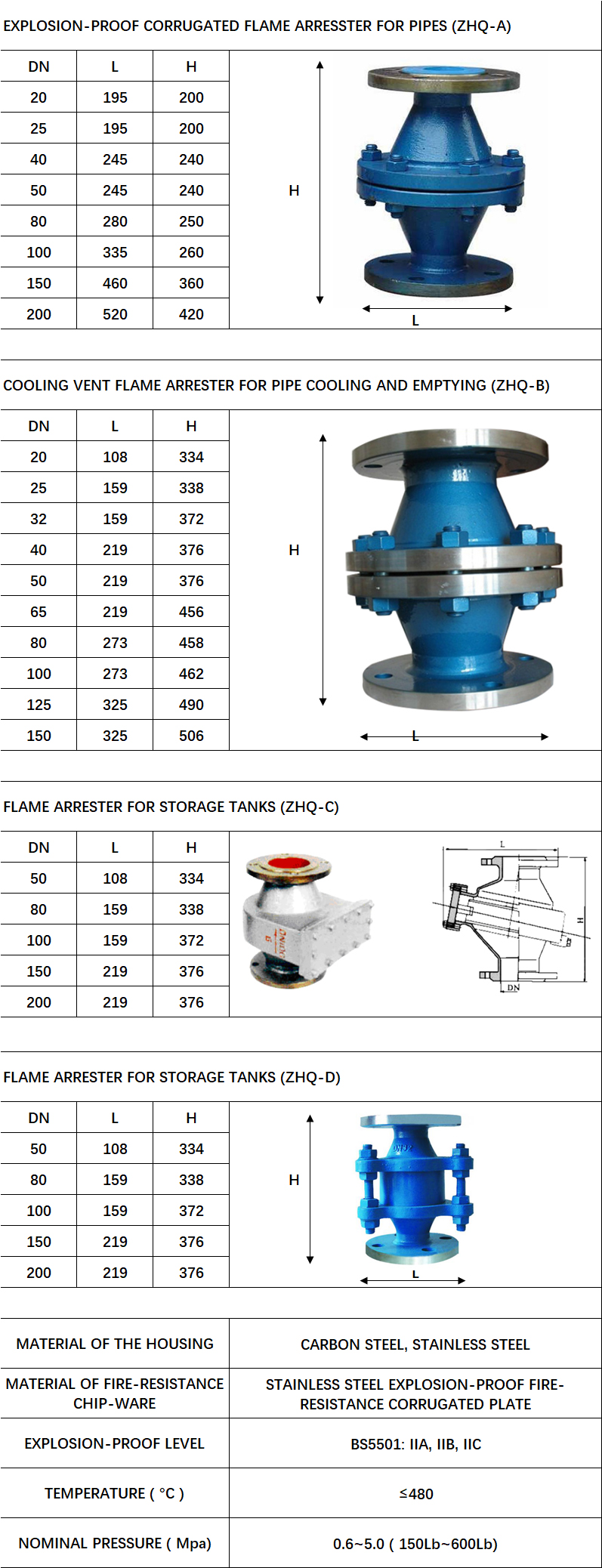

Flame arrester is safety device which stops flame of inflammable gas and liquid from spreading, and prevents backfire from causing explosion. It is usually installed on tanks or pipes which transport or discharge flammable and explosive gas, for instance, torches, Heating combustion system, Oil Gas Recovery System and other flammable and explosive gas system.

With the assistance of advanced technology from the UK and Germany, we developed the device with our progressive processing equipment and faultless testing equipment. The Corrugated Plate Flame Arrester we made is particularly applicable to many special mediums such as Hydrogen, oxygen, liquefied petroleum gas. And the following is the advantage of our device: compact structure, high reliability, explosion-proof and anticorrosion fire arresting chip-ware, strong water-resistance, easy cleaning etc.

Main Technical Parameters

Applicable to petrochemical products whose flashing point is lower than 60℃, such as Gasoline, kerosene, light diesel oil, toluene etc.

Temperature:≤480℃.

Material of the Housing: Carbon steel, aluminum alloy, stainless steel; SUS304, SUS304L, SUS316, SUS316L.

Material of Fire-resistance Chip-ware: Stainless steel corrugated plate.

Explosion-proof level: BS5501: ⅡA, ⅡB,ⅡC.

Standard for Manufacture and Testing: SY/T0512-1996.

Standard for Flange: HG/T20592-2009.

Please note in order contract if GB, SH, HGJ, JB, ANSI, JIS and other standards are required or there is a need for Pressure change.

EXAMPLE:

Ordering Information:

Choosing the proper flame arrestor is critical to the safety of equipment and personnel. Before ordering, please consult our technical team. And following basic information should be made clear before ordering:

Length of pipe between the arrestor and the ignition source without bends

Length of pipe between the arrestor and the ignition source with one 90° bend

Length of pipe between the arrestor and the ignition source with multiple bends

Flame stabilization at stoichiometric mixture and ambient temperature not to exceed 140°F (60°C)

Operating Pressure

Ordering Information:

Please make a safe product selection. When selecting products, the total system design must be considered to ensure safe, trouble-free performance, founction, material compatibility, adequate ratings, proper installation, operation and maintenance are the responsibilities of the system designer and user.

From quote to delivery, detail support can be offered.

1.CAD drawing

2.P&ID

3.Component selection

4.Bill of material

5.Professional services such as bending and welding

6.Testing to guarantee the system

7.Professional packaging and delivery

Standard packing or as customer request.

Within 7 days if instock, or according to the Order QTY and we'll detail you the date of shipment.