EVA Waterproof Board

- Thickness(MM)

- 1.2、1.5

- Width(M)

- 1.0、2.0、3.0、4.0

- Length(M/Roll)

- 20、30 or can be customized

- Square Meter(㎡/Roll)

- 20、40、60、80

Product Description

Product Description

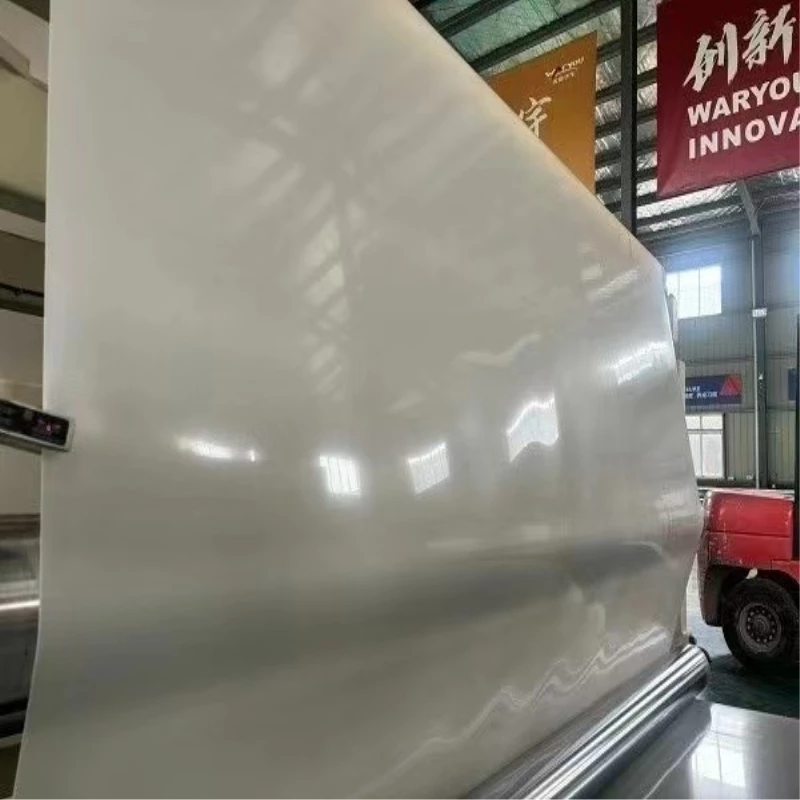

EVA plastic waterproof board is made from ethylene-vinyl acetate copolymer (EVA) as the primary raw material, with the addition of special additives and anti-aging agents. It is manufactured through processes such as melting, extrusion, calendering, molding, and coiling into a sheet material of a certain thickness. The appearance is generally semi-transparent white.

Product Specification:

|

Thickness(mm) |

1.2、1.5 |

|

Width(m) |

1.0、2.0、3.0、4.0 |

|

Length(m/roll) |

20、30 or can be customized |

|

Square Meter(㎡/roll) |

20、40、60、80 |

Product Performance:

|

Performance Name |

Technical indexes |

Typical value |

|

Tensile strength(23℃) |

≥16MPa2 |

18.8MPa2 |

|

Low Temperature Flexibility |

no crack -35℃ |

no crack -35℃ |

|

Tear strength |

≥60 KN/m |

122 KN/m |

|

Impermeability 30Min |

0.3MPa, no leakage |

0.3MPa, no leakage |

Product Features

1、 Optimal VA content for balanced high and low-temperature performance.

2、 No plasticizers or recycled materials, ensuring excellent product performance.

3、 Excellent physical and mechanical properties, high strength, tear resistance, high elongation, and good resistance to stress cracking.

4、 Resistant to corrosion from acids, alkalis, salts, and other media in concrete or soil, and resistant to mold.

5、 High adaptability to construction environments, good heat resistance, and low-temperature flexibility.

6、 Soft texture with good adhesion to the base layer, making installation convenient.

7、 Good workability, strong weldability, with lap joints welded using hot-melt welding. The welding parameters are adjustable, making construction simple, fast, and the waterproof layer reliably sealed.

How to Use

Construction Process: Clean the base layer → Lay the cushion layer → Lay the waterproof board → Handle lap joints → Deal with detailed node treatments → Quality inspection and acceptance → Rebar tying → Secondary lining construction

Construction Points:

1、 Base Layer Cleaning: The base layer should be flat, without sharp burrs, pipes, rebar, wire, etc. The corners of the base layer should be rounded or arc-shaped. Before laying the waterproof board, the base layer should be treated with cement mortar.

2、 Laying the Cushion Layer: The geotextile cushion layer should be laid as flat and naturally as possible, without being overly tight or forming large bumps at the corners. The cushion layer is fixed to the base layer with cement nails or expansion bolts and round washers mach with the waterproof board, arranged in a regular diamond pattern. The cushion layers are connected using a lap joint method, and the lap joints can be point-bonded.

3、 Laying the Waterproof Board: The waterproof board should be laid in the horizontal (circumferential) order of the station. Use the hot-melt method to fix the waterproof board onto the round washers, ensuring a secure bond to prevent the board from falling off during concrete pouring.

4、 Lap Joint Treatment: The lap joints are welded using a hot-melt double-seam welding method. The welding should be tight and without burning or puncturing.

5、 Quality Inspection and Acceptance: After welding, use an inflation method to test the welds. After laying the waterproof board, conduct a comprehensive inspection of its surface, and promptly repair any damaged areas. The patch should be cut with rounded corners, avoiding sharp angles such as triangles or squares. In case of any leak detected, the leaking welds should be fully manually rewelded.

Precautions:

1、 Operators must be trained before they can work on the site.

2、 Construction should not be carried out in rain, snow, or exposed to winds above level 5.

3、 The surface of the materials at the welding site must be wiped clean, free from water, oil, or dirt.

4、 Strictly inspect the welding quality, ensuring no missed or skipped welds.

5、 Protect the construction site during the process, and prohibit personnel wearing spiked shoes from entering the area where the waterproof board has been laid.

Product Application:

It mainly used for waterproofing projects in tunnels of railways and subways; waterproofing of culverts for roads and railways; and waterproofing, seepage prevention, and moisture-proof projects for various municipal engineering projects, sewage treatment pools, and civil air defense projects, among other underground construction projects.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.