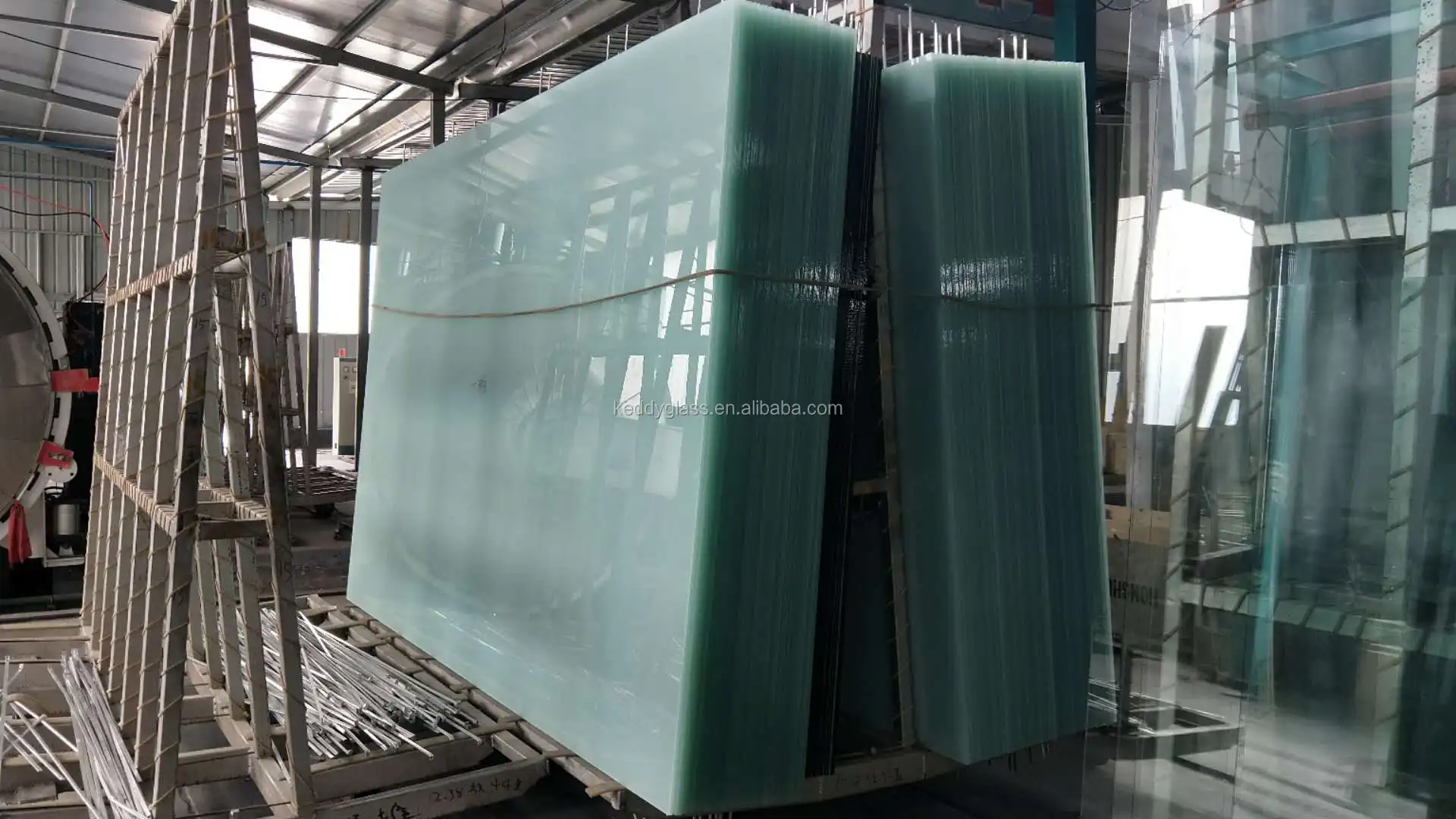

Laminated Glass is the construction of two lites of glass bonded together by an adhesive material--typically Polyvinyl Butyrol (PVB). This invisible PVB layer is designed to keep the glass integral to the structure upon breakage, rather than allowing the glass to shatter into otherwise large, sharp, and dangerous pieces. PVB also dulls the edges of broken shards of glass, significantly lowering the risk of injury. After undergoing a series of heating and pressing, the two lites of glass and PVB interlayer become one solid, durable glass construction.

Product | 3-19mm | Laminated glass | |||||

Glass thickness | 2440*6000mm | 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm | |||||

Glass color | Clear, Ultra clear, French green, Dark green, Euro grey, Dark grey, Ford blue, Dark blue, Ocean blue, Euro bronze, Dark bronze, Golden, Pink, Yellow, etc. | Clear, ultra clear, bronze, grey, blue, green, black, etc | |||||

PVB thickness | Tempered glass, Heat strengthened glass, Tempered glass with heat soak, Bent tempered glass | 0.38mm, 0.76mm, 1.14mm, 1.52mm | |||||

PVB color | Worthy export wooden crate, with plastic paper between each glass, suitable for export | Clear, green, blue, milk, gray, bronze, red, etc | |||||

Size | windows and doors in architecture | Min size: 200*200mm Max size: 2440*3660mm. | |||||

Feature | 1. Extremely high safety 2. Energy-saving building materials 3. Create aesthetic sense to buildings 4. Sound control 5. UV protection | ||||||

Application | 1. Windows,doors, 2. Skylights and canopies, 3. Glass stairs,balustrades, 4. Automotive windshield, 5. Facades and curtain walls | ||||||

Payment | 30% deposit, 70% after B/L copy | ||||||

Package | Sea worthy wooden crate with interlayer paper | ||||||

Delivery time | 15 days | ||||||

- 1.To ensure safe shipment, our glass will be taken good care of by this way.

2. Paper and Cork liner will be put between every two glass to prevent them hurt each other.

3. Glass will be put in suitable wooden crate with Corner Protectors.

4. Under wooden crate there will be legs for forklift easy loading and unloading.

- 1.To ensure safe shipment, our glass will be taken good care of by this way.

- 1.12 years experiences on toughened glass manufacturing and exporting.

2.We have strong technical support and production capacity.

3.Our factory close to the sea port, transportation is very convenience.,CAN DO DOOR TO DOOR

4.Professional sales team, offering personalized and dedicated services

5.Unique designed strong wooden cases and container fixed method can solve the problems of breakage.

6.Top quality toughened glass with CE, ISO9001,CCC,SGCC,ANSIZ97.1-2015,AS/NZS 2208 Certificate.

7.OEM is feasible, and welcome to visit our factory.

8.Favorable price and reasonable payment terms;

9.We can guarantee the delivery time.

GB15763.3,Chinese standard.

EN12543,European standard

EN12600,European standard.

ANSI Z97.1,American standard.

AS/NZS 2208,Australian standard.

Q1: How to judge the quality of float glass?

A1: Flatness, transparency, colorless, impurities, bubbles, etc.

Q2: How to reduce the self-implosion?

A2: The high quality float method is used for hot dip treatment, edge treatment and proper stress intensity. Pay attention to avoid side collision of glass during installation.

Q3: Scope of use of toughened glass?

A3: Safety is not involved in some parts of the building, but it is necessary to install toughened glass to improve the compressive strength and explosion-proof capacity,not to endanger the person safety

Q4: When toughened glass is broken, is the grain smaller the better?

A4: No, the smaller the particle, the easier it is to explode.

Q5: Can toughened glass and semi-toughened glass be made into laminated glass?

A5: Can't. The national standard stipulates: the glass that stresses the difference cannot make laminated glass, because in use process, the pressure that two pieces of glass bears is different.

Q6: Whether the laminated glass can fire, can the sound insulation?

A6: No, the smaller the particle, the easier it is to explode.

Q7: How many uv low-e glass can reduce?

A7: It is not fireproof glass, but has certain fireproof ability, also can soundproof, laminated glass is inside whole sound wave frequency range, in control noise is very good.

Q8: Does the air in the insulating glass do not oxidize the membrane?

A8: No, because there is a molecular sieve in the insulating glass, and the molecular sieve always keeps the air dry, so the membrane is not oxidized.

Q9: How much ultraviolet radiation can low-e glass reduce?

A9: It can reduce uv by 14% compared to heat reflecting glass. That's a 25 percent reduction in uv radiation compared to white glass.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.