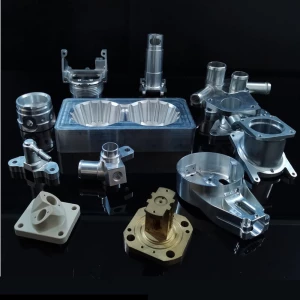

Our facility features a variety of CNC turning machines of different sizes and capabilities to meet pretty much any manufacturing requirements. In addition, we have a team of highly qualified engineers and machinists who work with our quality control experts, ensuring that our products are always done right and satisfy the required standards and regulations. a wide range of material options for CNC turning contains Stainless steel, steel, brass, bronze, copper, aluminum, iron, alloy, and plastic POM,PTFE,PC,PEEK,PET,PEI,PA6..., etc

Why CNC Turning?

CNC turning is ideal for creating cylindrical shapes or parts that are symmetrical near their axis, for example, a chess pawn, bolts, rivets, ball bearings, and washers. CNC turning also solves some of the manufacturing challenges associated with CNC milling. For example, it allows you to create undercuts or relief grooves easily, whereas CNC milling machines require specialty cutting tools to achieve this. CNC turning machines also allow cutting operations to occur along 3-, 4-, or 5-axis, allowing you to perform taper turning, knurling, threading, and parting, among other operations. This subtractive manufacturing process is particularly suited for rapid prototyping and low volume production. Nevertheless, CNC turning can be used in tandem with CNC milling to create high-quality parts accurately while meeting tight tolerances.

Advantages of Brightstar’s CNC Turning Services

Our highly qualified engineers and machinists work with our dedicated quality control team to ensure that products are done right the first time and satisfy customers’ requirements and standards. Our engineers and machinists utilize best-in-class software, including SolidWorks, MasterCAM, AutoCAD, and PRO-E to create 3D CAD models that satisfy the design for manufacturing (DFM) criteriaㅡwhich mean we design parts for ease of manufacturing. We are the best at providing high-quality CNC turning services while offering competitive prices, allowing you to complete your product development project cost-effectively. We are experts in rapid prototyping, and our low-volume CNC turning services can act as a bridge between the prototyping and final stages of your product development process. We adhere strictly to the requirements of several industrial, quality, and environmental systems standards, and our facility is ISO 9001:2015,and ISO 9001:2016 certified.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.