China suppliers liquid sampler of closed loop liquid sampling system in petroleum industry

High quality closed loop gas sampling system

This is a new non-leaking, pollution free sampler which is used for sampling for all kinds of toxic, corrosive, explosive and flammable samples under low pressure, high pressure or medium pressure from petrochemical process pipe.

We can also design and manufacture sealed sampling device to meet special technical and safety requirements.

| Materials | 304, 304SS, 316SS |

| Cylinder Assembly | 500 ml cylinder |

| Needle Valves | |

| NPT Quick-connects | |

| Sampling Valve | Ball Valves: Seat and O-ring Max. Working Pressure: 103 bar @ 20 ℃ Temperature Range: -18℃ to 232 ℃ |

| Other Accessories | Metal Hoses |

| Pressure Gauge | |

| Conections | NPS 1/2 Flange |

1. Sampler needle desgined to prevent blocking ,ensure spacer intact seal in leakage environment.

2. Separated location for sampler needle and emitting needle ensure reliable,save discharge channel for gas medium.

3. Sampler needle designed to directly demount and fix ensures easily and easily maintenance, unnecessary removal valve and pipe.

4. Purge function ensure sampler needle clean and representative sampling.

1. Samplers for low pressure liquid.

2. Samplers for rust and dangerous liquid.

3. Sampling pipe line or at the top of reactive tank on the condition of the low pressure.

1. It is necessary to add a cooler, ensuring safety in gas sampling in high temperature.

2. Selecting Purge function in rust and dangerous environment, giving and additional safety in gas sampling.

3. In order to successfully collect gas sample, pre-heat is needed when it is under too low temperature or the media is sensitive to the low temperature.

4. Add a filter to extend life of equipment.

A. Liquid sampler bottle and sround

Optional sampler bottle: borosilicate bottle maximum heat-resistance 500 ℃.

Glass bottle:

Sampler bottle shroud gap would be used for viewing the liquid level.

B. Liquid sampler needle and gasket component

Needle and gasket design for protecting against blocking in liquid sampling process

Needle and accessory

1. Needle component designed to quip with two pieces of needle in the head.

The long needle is for sampling, the short one is for gas vent which is used to release the gas replaced by liquid or the mixture gas in liquid and vapor.

2. The valve shall not be set in vented openings in order to assure fluent exhaust passage. Checkvalve is suggested to fix in vent opening when the equipment is out of operation so as to prevent accidental gas from returning back to pipe systems.

1.robber

Rubber has well resilience and mechanical function but easily aged by exposing in scorching sunlight .

it apply to acid,alkaline and non-corrosive medium.

2.silica gel

silica gel has well resilience and mechanical function.it has best thermal -resistant and antioxidation without aging phenomenon ,and it shall not react with majority of chemicals except of fat .

3.polytetrafluoroethylene silica gel

TCS combines the advantages of polytetrafluoroethylene and silica gel. Its thermal -resistant and chemical inertness considered to be the best selection for high temperature sampling.

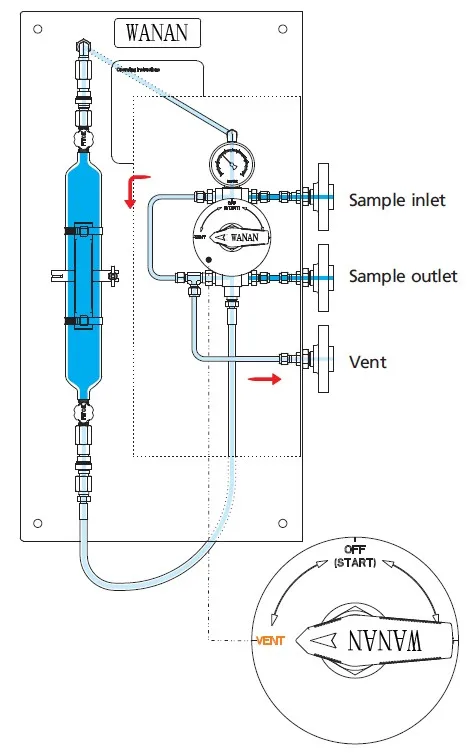

1- Preparation

Install the sample cylinder and connect the hose to bottom side of the cylinder. Open the needle valves at both ends of the cylinder.

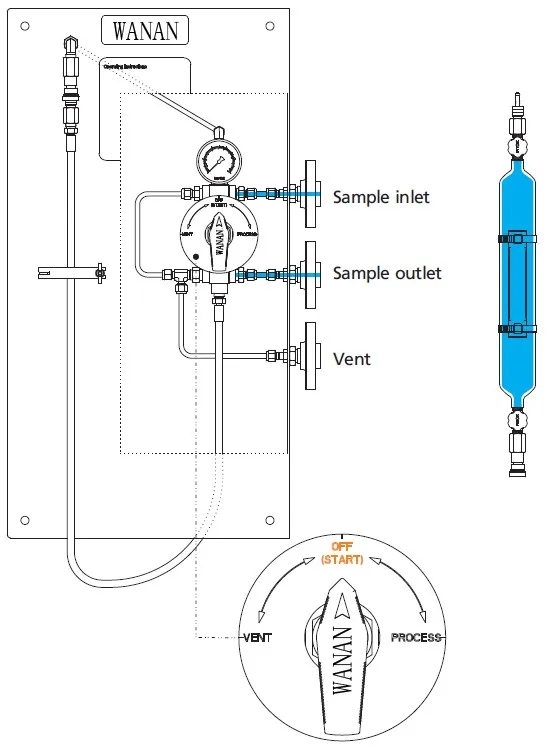

2- Sampling

Turn the handle to the “PROCESS” position, allowing the sample to flow continuously into and fill the cylinder. Hold for a period of time to ensure representative sampling.

3- Off

Turn the handle to the “OFF” position. Close the needle valves at both ends of the cylinder.

4- Depressurization/vent

Turn the handle to the “VENT” position, connecting the sampling line with the vent line to depressurize and discharge the residual sample.

5- OFF

Turn the handle to the “OFF” position and disconnect the hose. Remove the cylinder and connect the hose to the top quick connect to complete the sampling process.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.