CHINA FACTORY GT-1912TX (EpsonI3200-A1x12)1.9m Industrial High Speed Digital Sublimation Printer

- Model

- GT-1912 TX

- head printer

- I3200-A1X12

- colors

- CMYK

- Printing speed

- 1PASS-500SQM/H

- X-axis transmission

- Belt drive / maglev

- Print wide width

- 1900MM

- Ink cartridge Kind

- High-concentration heat transfer ink

- Ink cartridge Capacity

- 10 L

- Printing resolution

- 2400DPI

- Voltage

- AC220V±5% 16A 50Hz

- Power

- MAX 11KW

- RIP

- HOSONRIPRINT

- Machine size / weight

- 3734x1232x1588 mm / 850 kg

- Package size /weight

- 3860x1130x2000 mm / 890 kg

Other recommendations for your business

|

It adopts advanced board control technology, equipped with 15/16 i3200-A1 print heads and 3.5pl ink droplets. The industrial-grade design ensures the durability of the print head. The new automated production scheme, high-strength industrialdesign structure, can be equipped with 3000 meters of raw paper with performance, and the unattended automated production scheme can be fully realized, so that the productivity has been further improved. |

- Post-receiving device, A with a 3,000-meter whole roll of original paper carrying performance;

- High stability THK silent double guide rail, and improve the stability of printing to ensure high-quality continuous output;

- The air-guided suction platform makes the material run smoothly, the paper is not easy to bulge, improves the output quality, and the platform calibration and adjustment is more convenient;

- Multi-position guide roller material paper is more uniform, high-precision output, and it is not easy to have press wheel printing and paper wrinkle;

- The thickened wall panel structure is more stable for long-term high-speed operation, and can carry heavier materials;

- The front section + bottom multi-stage drying is more convenient for upper and lower materials, improves drying efficiency, and is more suitable for customers to print;

- Effectively solve the step deviation and speed difference caused by the diameter of different materials to ensure that the collection is neat;

- It can meet the needs of mass production, save loading and unloading time, and improve production efficiency;

|

|

|

|

|

Front + bottom drying device, stable and efficient, fast drying |

Independent adjustable lifting paper rubbing wheel effectively solves problems such as uneven media drumming during printing. |

Ink-deficient alarm beeping device provides customers with more intuitive and convenient services. |

Plue roller feeding system ensures that the material is more stable and neat. |

|

|

|

|

|

10L large ink barrel: Provide a stable ink supply system to ensure amazing continuous printing. |

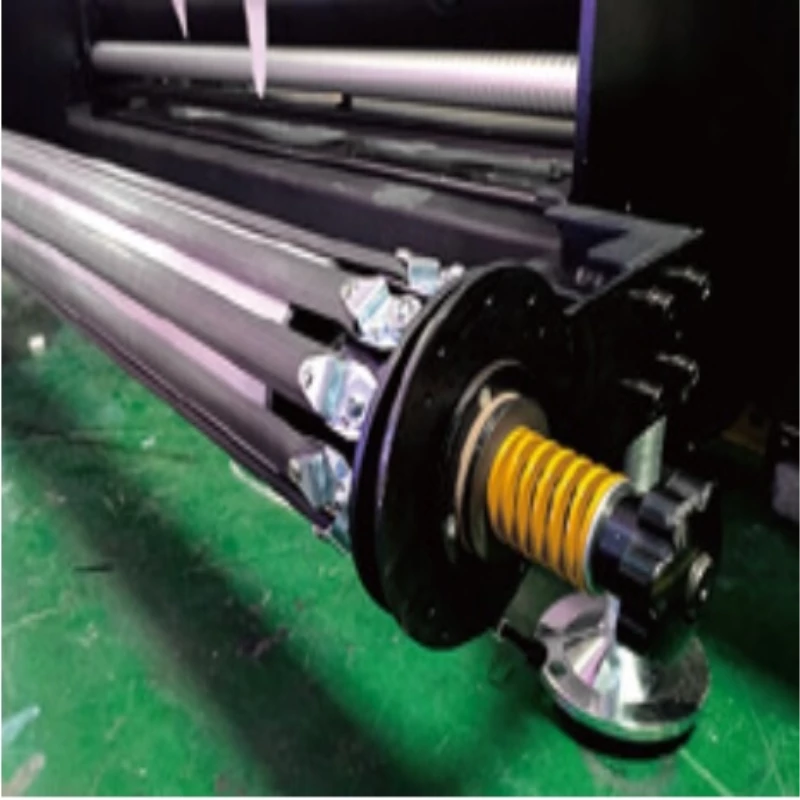

The AC servo motor is combined with a high-quality reducer to provide stable high-speed movement and smoother paper delivery. |

Equipped with widened and thickened beams and THK high-quality silent double rails, the equipment is more stable in high-speed printing. |

Two external infrared drying systems are used for drying control at the front end and bottom. |

Widely used: clothing, home decoration fabrics, T-shirt printing, canvas bags, cushions, scooters, flags, textile fabrics, etc Digital Sublimation Printer.

Supplier's popular products

Contact Supplier

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.