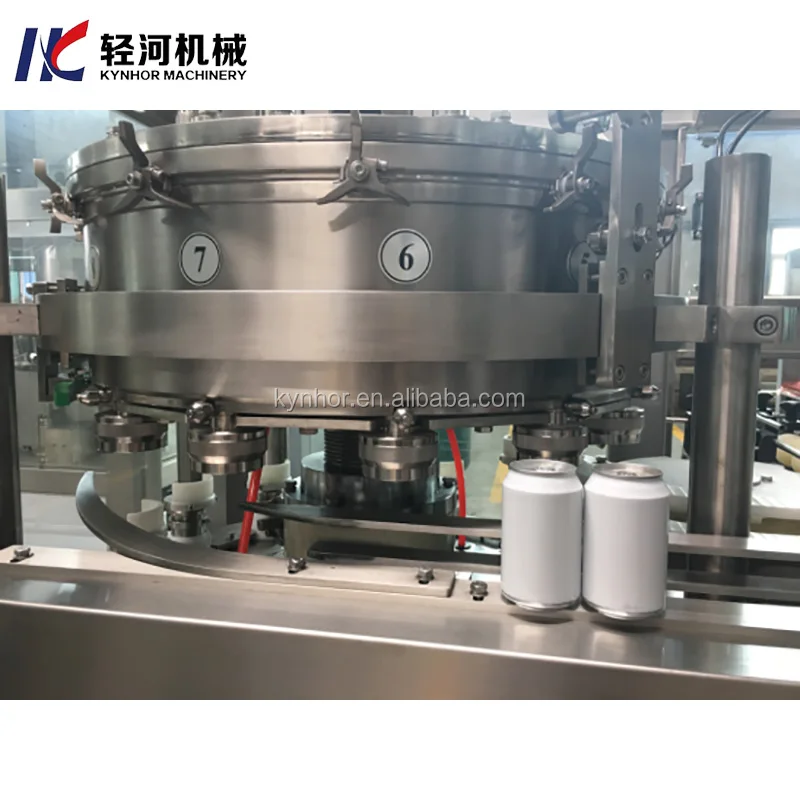

Automatic PET can/Aluminum can filling machine for beer/soda/energy drink/juice

Automatic PET can/Aluminum can filling machine for beer/soda/energy drink/juice

Products Introduction

1.The iso-pressure (iso-barometric) filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others.

2.Besides using photo-electronic detectors to detect the running of every important sub-process, it employs PLC from OMRON for automatic control of the whole process and new type air-channel for bottle-loading featuring speediness and damage-free of bottle. The handing-over of bottles between two linking structures is fulfilled by applying clamping-bottle-neck method. For bottle of different shape only a few parts need to be changed and the substituting is simple, which shows the machine is of good adaptability.

High automation and easy operation make it an ideal option for beverage companies.

Excellent Quality automatic PET can/Aluminum can filling machine for beer/soda

Characteristics:

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Model | Capacity | Motor power (kw) | Dimension (L*W*H) | Weight |

BGF6-6-1 | 400-500 | 2kw | 1800*1800*2200 | 2500 |

BGF14-12-4 | 1200-1800 | 2.2kw | 2000*1800*2200 | 3000 |

BGF18-18-6 | 3000-4000 | 3.7kw | 2460*1720*2650 | 3500 |

BGF24-24-8 | 5000-6000 | 5.5kw | 3100*2100*2650 | 4500 |

BGF32-32-10 | 7000-8000 | 6.5kw | 3500*2500*2650 | 5600 |

BGF40-40-12 | 8000-90000 | 7.5kw | 4600*3300*2650 | 6800 |

BGF50-50-12 | 13000-15000 | 11kw | 5300*4500*3400 | 7600 |

BGF60-60-15 | 18000-20000 | 15kw | 6500*4500*3400 | 9800 |

How to trust us !

1.Kynhor cooperates with Alibaba who will supply you a lot of service to protect you .

2.Kynhor is registered in the Chinese business administration and has the right to operate and sell it legally.

3.Kynhor has a professional engineer team who all have more than 15 years experience in beverage filling machine manufacturing .

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station or the airport near our city.

3.If we get the permission of the customer who has brought the machines from us,we can tell you our customers' contact information,you can go to visit their factory.

4.We provide you with free debugging .

Customized service

1.We can design the machines according your requirements(material,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

2. We can offer free technical support and consultation such as design your factory,draw the factory layout and so on.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty with spare parts free and life-long technical support .

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.