Automatic Bottled Water Bottling Germany/Complete Drinking Bottle Filling Plant

Automatic Bottled Water Bottling Germany/Complete Drinking Bottle Filling Plant

The machine is a automatic multiple-funcition washing, filling and capping unit. It is used in washing, filling and sealing all kinds of no gas contained liquid, such as mineral water, pure water and fruit juice. The line has features of unique design, new style, complete functions, multi-purpose, convenient in operation, beautiful construction, high automaticity.

1. Automatic Bottling 3 in 1 Filling Machine adopt Rinsing / Filling / Capping 3-in-1 technology, PLC control, Touch Screen, it is mainly made of SUS304 or SUS316.

2. It is used for filling kinds of non-carbonated water, such as still water, drinking water. mineral water, spring water, flavored water.

3. Its usual production capacity is in 2000-15,000 bph, 0.3-2L PET bottle is available.

4. Pivotal electrical part use Mitsubishi, OMRON, SIEMENS.

5. Filling accuracy is more or less than 1%.

6. We can provide bottle blowing machine, bottle filling machine, labeling machine,wrapping packing machine etc. complete plant solution for PET bottle. with optional capacity from 2,000-15,000BPH.

Technical Data

| Model |

Washing heads | Filling heads | Capping heads | Capacity(B/H) | Motor power(KW) | Overall dimension(MM) |

| CGF8-8-3 | 8 | 8 | 3 | 2000-2500 | 1.2 | 2000*1400*2300 |

| CGF14-12-5 | 14 | 12 | 5 | 2000-4000 | 1.5 | 2100*1400*2500 |

| CGF16-16-5 | 16 | 16 | 5 | 5000-7000 | 2 | 2250*1600*2600 |

| CGF18-18-6 | 18 | 18 | 6 | 6000-8000 | 2.2 | 2460*1720*2650 |

| CGF24-24-8 | 24 | 24 | 8 | 8000-12000 | 3 | 3100*2100*2650 |

| CGF32-32-10 | 32 | 32 | 10 | 12000-15000 | 4 | 3500*2500*2650 |

| CGF40-40-10 | 10 | 40 | 10 | 16000-20000 | 7.5 | 4600*1800*2650 |

| CGF48-48-12 | 48 | 48 | 12 | 20000-24000 | 9.5 | 5200*4500*3400 |

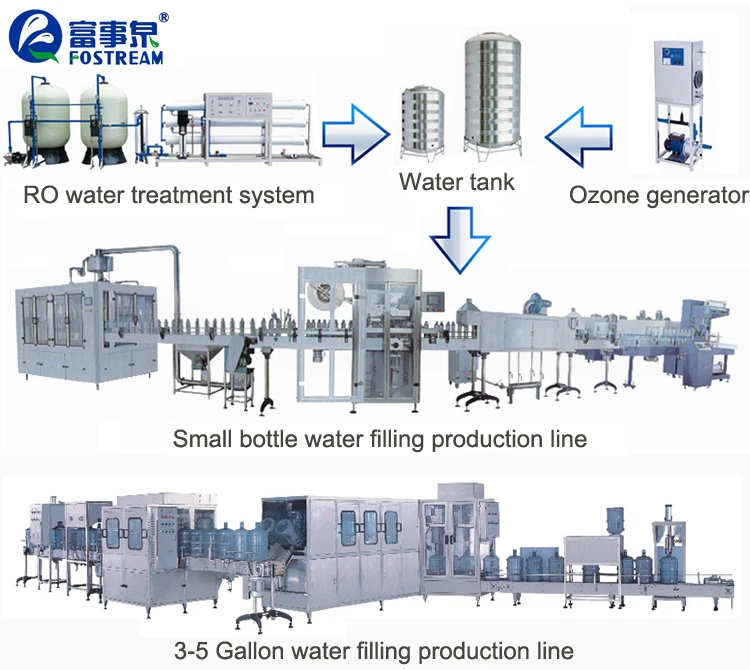

1).Full Automatic Small Bottle Filling Production Line

A.Bottle production line (PET Resin-Injection moulding machine-Bottle blowing machine-PET bottle)

B.Water treatment system (Raw water-Pump-Silica sand filter-Carbon filter-Water softer-Reverse Osmosis-UV sterilizer-Ozone generator-Finished water tank)

C.Filling&Packing part Bottle unscrambler-Air conveyor-Washing, filling, capping 3 in 1 machine-Light checker-Blow dryer-Dater printer-Labeling machine-Packing machine-Stock.

2).Semi Automatic Washing-Filling-Capping Machine

(For Pure Water, Carbonated Beverage,Fruit Juice Filler)

3).3-5 Gallon Water Fillng Production Line

Installation and commissioning

After the equipment arrived buyer's , workshop, the buyer should take it's place for each equipment according to the supplied ; layout; the seller l will d send the experienced technician to guide the installation and debugging and trail ,production, and fulfill the designed capability within the designed time. The installation, debugging and g training is about 7 days.

Training

The seller will supply technical training to the buyer. The training is includes: equipment structure and maintenance, control and operation. After training, the technicians of the buyer will grasp relevant operation and maintenance skills, and could adjust the technologies more skilled, and can deal with all kinds of malfunction in time.

After-sales services

1.After qualified of the equipment, the seller will supply one year guarantee, control system one year guarantee, free charge for wearing parts, and other spare parts with cost price.

2.Within guarantee period, the technicians who accepted training should strictly obey the requirements asked by the seller to operate the equipment and maintenance, to find the common malfunctions and fault clearing in time;

3.If the technicians of the buyer couldn't solve the problems themselves, the after-sales department will supply long range guide service by phone;

4.If relevant measurements couldn't solve the problems, the seller will send the technicians to the buyer factory, clear the fault or relevant technical problems on site, the charges will reference to the installation and debugging charges.

5.After guaranteed, the seller will supply widely favorable technical support, after-sales service for the lifetime: favorable price for the wearing parts and other spare parts.

Packaging & Shipping

Packaging: International standard export package;

Terms: T/T, 30% down payment, and the balance 70% prior to the delivery out of factory.

Shipping: 30 working days after receiving 30% deposit of total amount of contract or irrevocable L/C at sight.

Company Management

Our company has different departments to finish different things, the sales in our company has been trained about the machines ,they are professional to help you.

Quality Control

We have the single quality department,that make sure the material of the raw materials is good,and ensurethe machine running smoothly.

Export market

Our machine has been sold to more than 30 countries,almost of the customers are satisfied with the machines and our service.

Q1.Are you a factory or trading company?

A1.We are a professional water treatment and filling equipment manufacturing factory that set up for 20 years.We always pay attention to the development of the industry !.We can give a discount according to the quantity of machine you purchase.

B1.At the same time,we take effective measures to control the production process for ensuring the quality of products.

Our products are certified.And we can supply SGS, BV, TUV, ISO9001, ISO14001, OHSAS18001, CE certification.

C1,Website: http://www.jmangel.com Website on alibaba: http://jmangel.en.alibaba.com

Q2.Where is your factory located? How can I visit there?

A2:Our factory is located in No.141-143 plant, Qingnian Road, Chaolian Town, Pengjiang District, Jiangmen, Guangdong, China, All our clients, from home or abroad, are warmly welcome to visit us!

Q3:All of your products are made by your self or compacted via purchasing the others?

A3: We have independent technical team who focus on making machines, all the products are made by our technical team for packing plant.

Q4.What products does your company offer by yourself?

A4:We are specialized in RO water treatment machines,UF water treatment machines,small bottle filling machines and 5 gallon filling machines etc.

Q5: How can I know your machine works well?

A5: Before delivery, we shall test the machine working condition for you.

Q6: Do you have technical support after we purchased your machines?

A6: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q7.What’s your warranty?

A7:Our warranty is 1 year. But normally, our machine can work 5 years before repair.

Company Name:Jiangmen Pengjiang Angel Drinking Water Equipment Co., Ltd.

Operational Address:No.141 to 143 plant,Qingnian Road,Chaolian Town,Pengjiang District,Jianmen City,Guangdong Province,China.

Zip Code: 529090

Tel:+86-750-3723390

Mobile Phone:+86 15322663825

Email:jmangel(at)jmangel.com

Website:http://www.jmangel.com

Website on alibaba.com: jmangel.en.alibaba.com

| Related Products | ||

| ||

| Barrel Water Filling Machine Production Solution | ||

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.